Perlite polyphenylene compound filling block, method for preparing same and filled floor plate construction method

A construction method and filling block technology, which can be used in manufacturing tools, building materials, ceramic molding machines, etc., can solve the problems of heavy floor filling materials, flammable and easily deformed, difficult to handle pipelines, etc., so as to save the amount and cost of positioning steel bars. Low cost and the effect of reducing the amount of rebar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

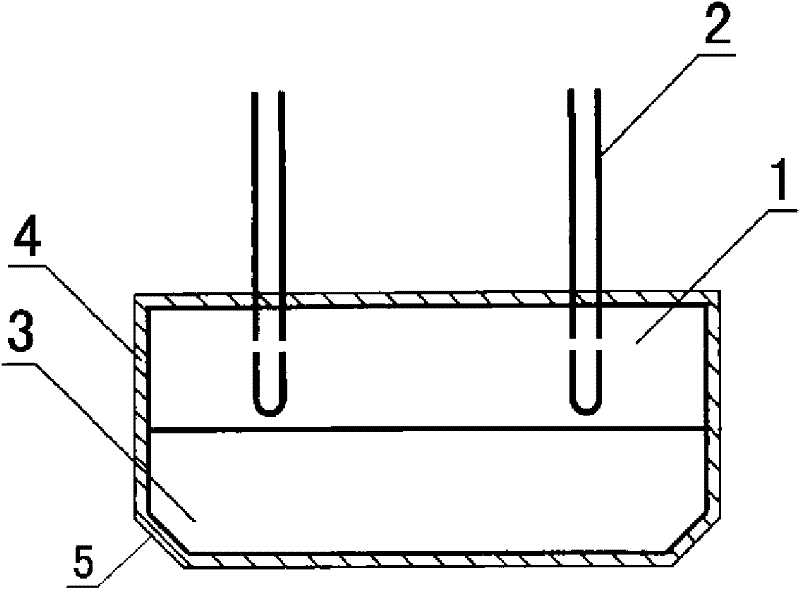

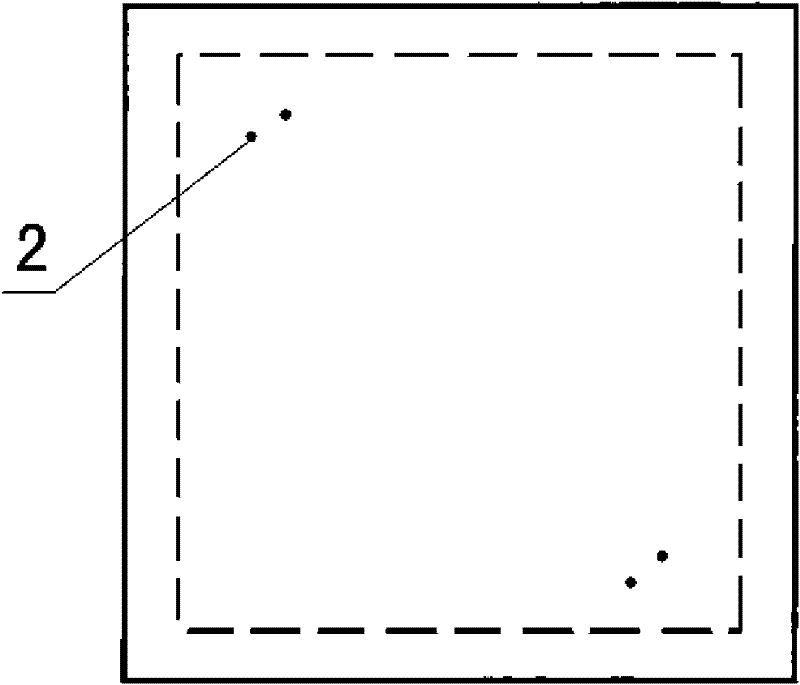

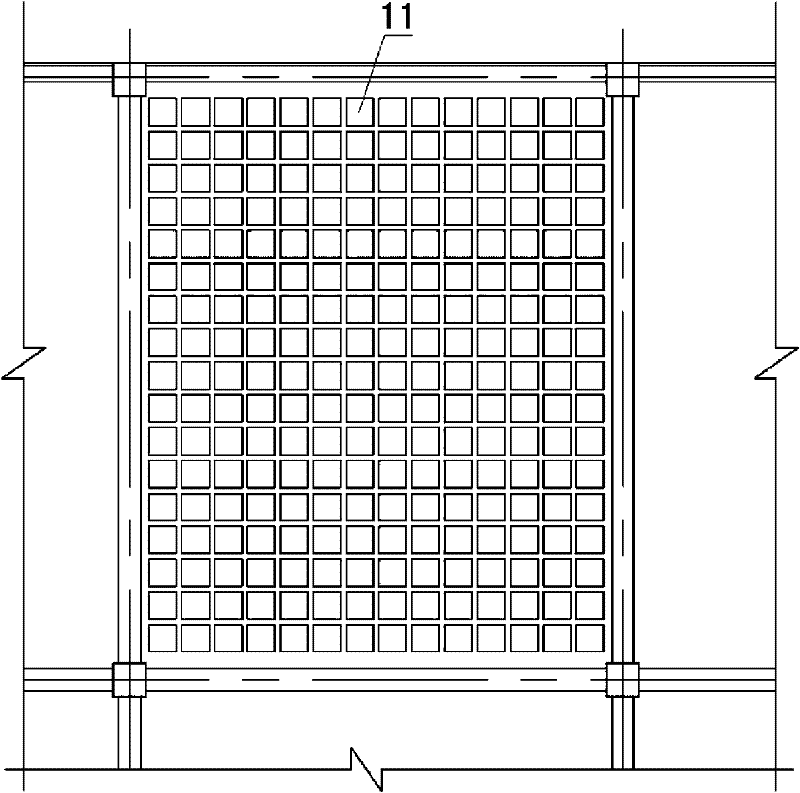

[0044] For examples of perlite polystyrene composite packing blocks see figure 1 , figure 2 As shown, it is a straight parallelepiped with a rectangular top surface, which is characterized in that: the block is formed by superimposing a rectangular expanded perlite aggregate block 1 and a polystyrene board 3 up and down, and the outer surface of the block is wrapped with a plastic tape 4, wherein A positioning metal wire 2 is pre-embedded in the expanded perlite agglomeration block 1, the bottom of the positioning wire 2 is U-shaped, and the two ends of the positioning wire 2 pass upward through the expanded perlite agglomeration block 1 and extend to the bottom of the plastic tape 4. outside. The junctions between the bottom surface of the straight parallelepiped and the four vertical surfaces are sloped or arc-shaped surfaces, and the four bottom corners are all eight-character chamfers 5 or arc angles. This embodiment is a cuboid. The length of the block 1 is 200-800 mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com