Production method of atmospheric-corrosion-resistant high-strength extra-thick Q390GNH steel plate

A technology that is resistant to atmospheric corrosion and production methods, applied in the field of wide and thick plate production, can solve problems such as high sensitivity to welding cracks, unstable quality, and long process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

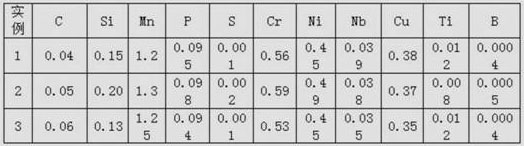

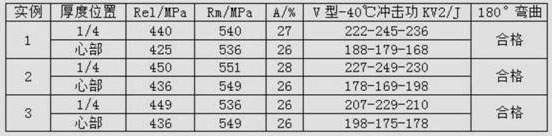

[0030] Through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling, heat treatment and other processes, the 120mm extra-thick and atmospheric-resistant steel with the chemical composition described in Table 1 below is obtained. The high-strength steel plate Q390GNH is corroded, and the process parameters and mechanical properties are shown in the following tables 1 and 2.

[0031] Table 1 Chemical composition (Wt%) of 120mm extra-thick atmospheric corrosion-resistant high-strength steel plate Q390GNH

[0032]

[0033] Table 2 Mechanical and mechanical properties of 120mm extra-thick atmospheric corrosion-resistant high-strength steel plate Q390GNH

[0034]

[0035] It can be concluded from the above examples that the steel plate produced by the present invention meets the design requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com