Preparation method and application of improved tin-based perovskite thin film

An improved perovskite technology, which is applied in the field of preparation of improved tin-based perovskite thin films, can solve problems such as excessively fast crystallization of tin-based perovskite, low performance of solar cells, and non-dense thin films, and achieve excellent crystallization Sexuality and vertical orientation, suppression of surface defects, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of an improved tin-based perovskite film and solar cell:

[0034] Step 1: Cut the ITO conductive glass into square pieces with a side length of 2.5cm, and ultrasonically in 2% (volume ratio) Triton X-100 ultrapure aqueous solution, absolute ethanol, ultrapure water, and absolute ethanol Wash for 30 minutes each. After purging with nitrogen, it was cleaned with UV-ozone for 20 minutes. The PEDOT:PSS solution was dropped on the above-mentioned ITO conductive glass, spin-coated at 5000rpm for 45s, and annealed at 135°C for 20 minutes to obtain an ITO substrate containing a hole transport layer.

[0035] Step 2: 298mg (0.80mmol) stannous iodide, 117mg (0.68mmol) formamidine hydroiodide, 30mg (0.12mmol) phenethylamine hydroiodide and 52mg (0.40mmol) 1,3-dimethyl The imidazolidine-2-thione was dissolved in a mixed solvent composed of 800 μL N,N-dimethylformamide and 200 μL dimethyl sulfoxide to obtain a perovskite precursor solution containing cyclic thione.

...

Embodiment 2

[0042] Preparation of an improved tin-based perovskite film:

[0043] Step 1: Same as in Example 1 above.

[0044]Step 2: 298mg (0.80mmol) stannous iodide, 117mg (0.68mmol) formamidine hydroiodide, 30mg (0.12mmol) phenethylamine hydroiodide, 47mg (0.36mmol) 1,3-dimethyl A mixture consisting of imidazolidine-2-thione and 5 mg (0.04 mmol) 1,3-dimethylimidazoline-2-thione dissolved in 900 μL N,N-dimethylformamide and 100 μL dimethyl sulfoxide solvent to obtain a perovskite precursor solution containing cyclic thioketones.

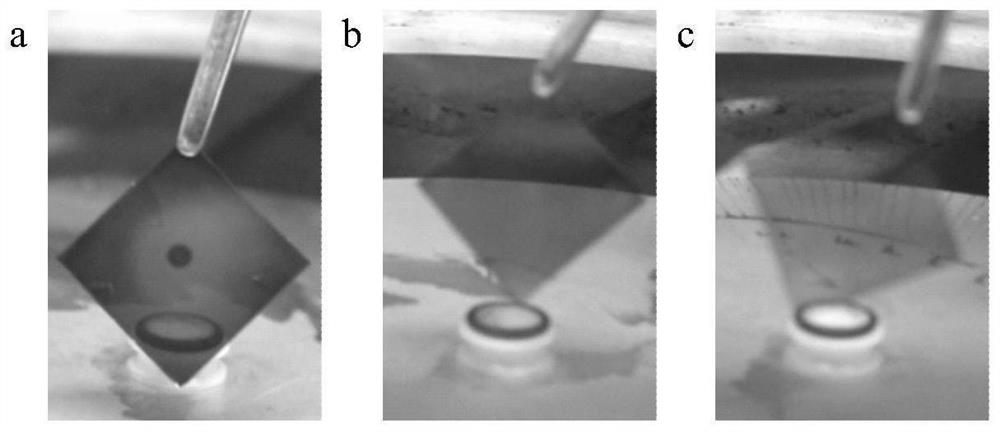

[0045] Step 3: Add the precursor solution prepared in step 2 onto the ITO substrate obtained in step 1 under nitrogen atmosphere. First spin coating at 1000rpm for 10s, then spin coating at 5000rpm for 34s, during which 600μL of toluene was injected to form a light brown transparent film layer, as figure 1 as shown in c. After the spin coating, it was annealed at 80° C. for 10 min to obtain a perovskite film containing 1,3-dimethylimidazoline-2-thione.

...

Embodiment 1

[0048] Preparation of a tin-based perovskite thin film and solar cell:

[0049] Step 1: Same as in Example 1 above.

[0050] Step 2: Dissolve 298mg (0.80mmol) stannous iodide, 117mg (0.68mmol) formamidine hydriodide, 30mg (0.12mmol) phenethylamine hydriodide in 800μL N,N-dimethylformamide and 200 μL dimethyl sulfoxide to obtain a perovskite precursor solution without thione compounds.

[0051] Step 3: Add the precursor solution prepared in step 2 onto the ITO substrate obtained in step 1 under nitrogen atmosphere. First spin coating at 1000rpm for 10s, then spin coating at 5000rpm for 30s, injecting 600μL of toluene during this period to form a dark brown, rough and whitish film, as figure 1 as shown in a. After the spin coating, it was annealed at 70° C. for 10 min to obtain a tin-based perovskite film without thioketone compound.

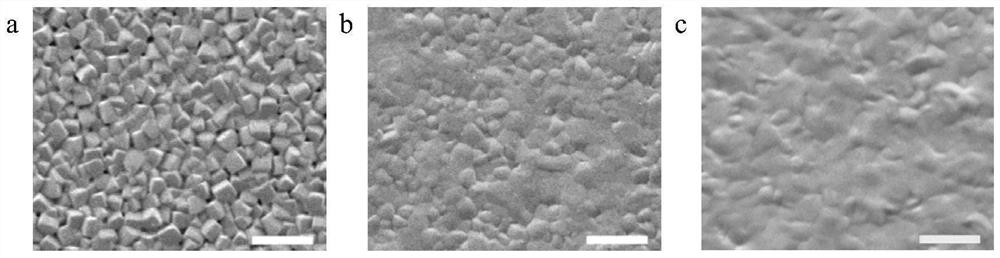

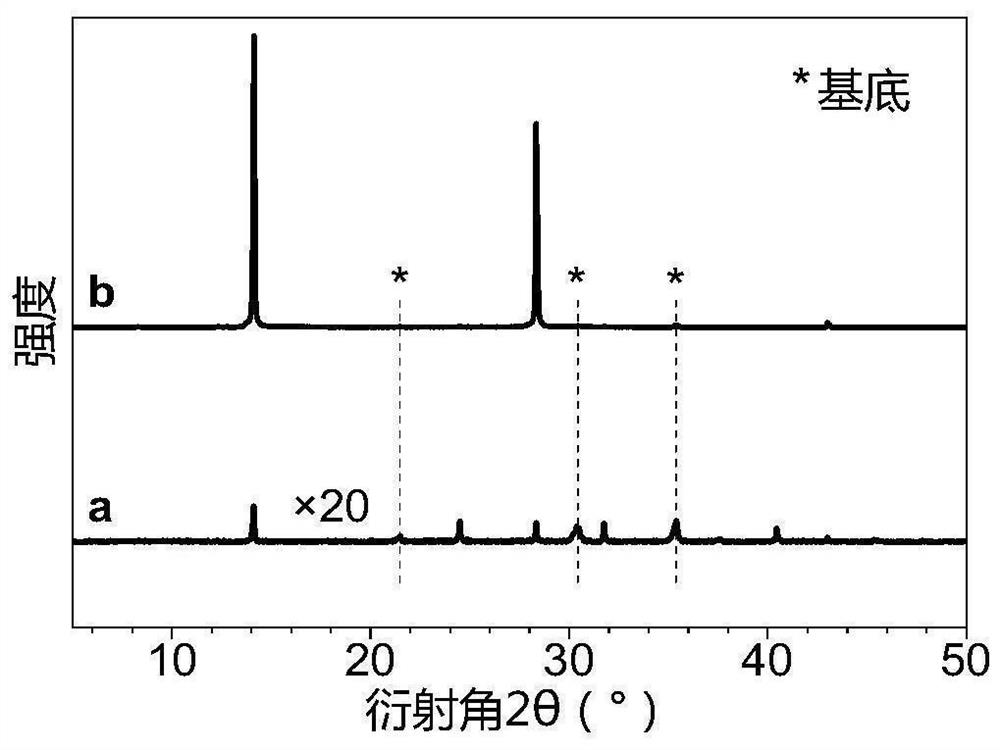

[0052] The scanning electron microscope results of the tin-based perovskite thin film prepared above are as follows: figure 2 As shown in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com