Ti-Al-C MAX phase coating and low-temperature phase forming preparation method thereof

A ti-al and coating technology, which is applied in the field of low-temperature phase formation preparation of Ti3AlC2MAX phase coating, can solve the problems of unsatisfactory synthesis conditions, long diffusion coefficient, high synthesis temperature, etc., and achieve a denser, smoother, rougher surface Low density, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

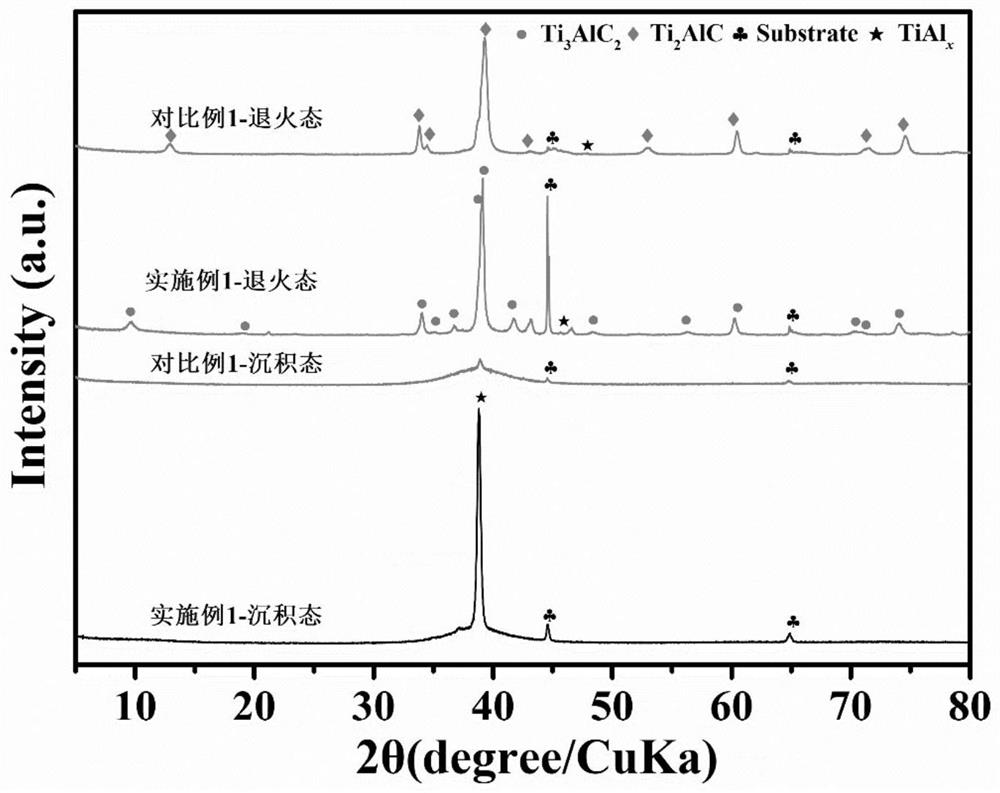

Embodiment 1

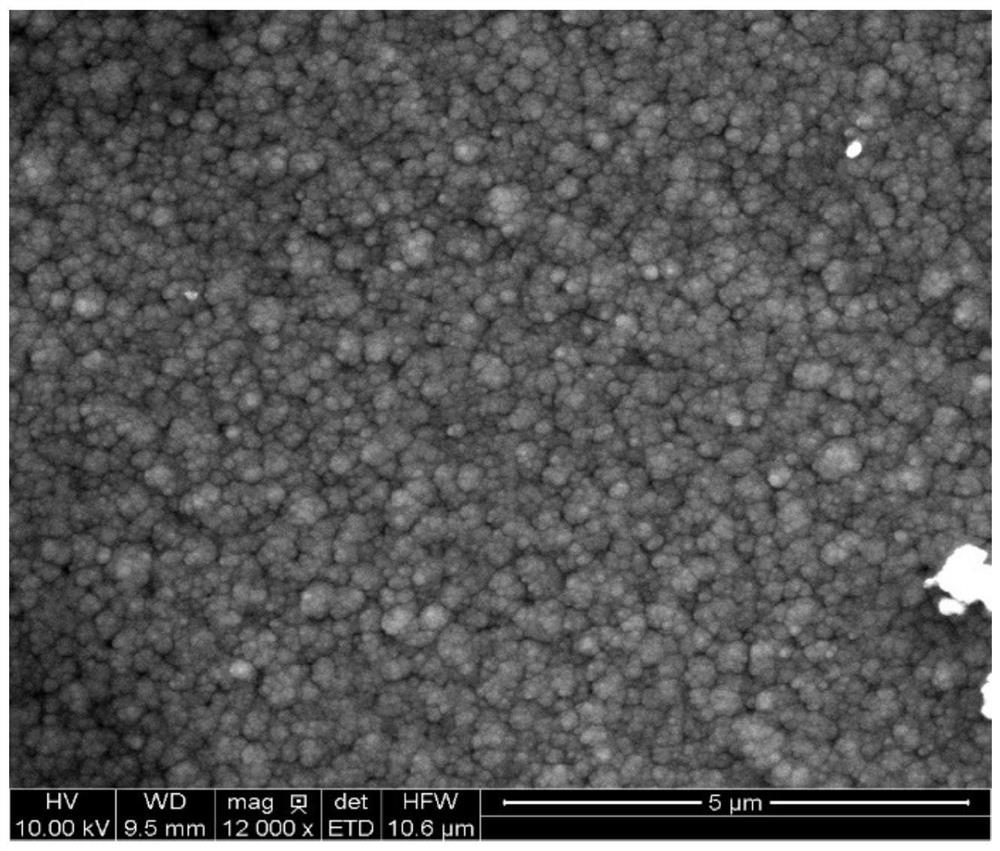

[0035] In this embodiment, the base material is 1Cr11Ni2W2MoV stainless steel, and the Ti on the base surface 3 AlC 2 The specific preparation steps of the MAX phase coating are as follows:

[0036] Step 1: Use 400#~2000# SiC sandpaper to polish the surface of 1Cr11Ni2W2MoV stainless steel in sequence, and then use diamond abrasive paste to polish for 20 minutes;

[0037] Step 2: Place the ground and polished 1Cr11Ni2W2MoV stainless steel substrate in acetone for 10 minutes of ultrasonic cleaning, then dry it with cold air and paste it on the sample holder with conductive adhesive for later use.

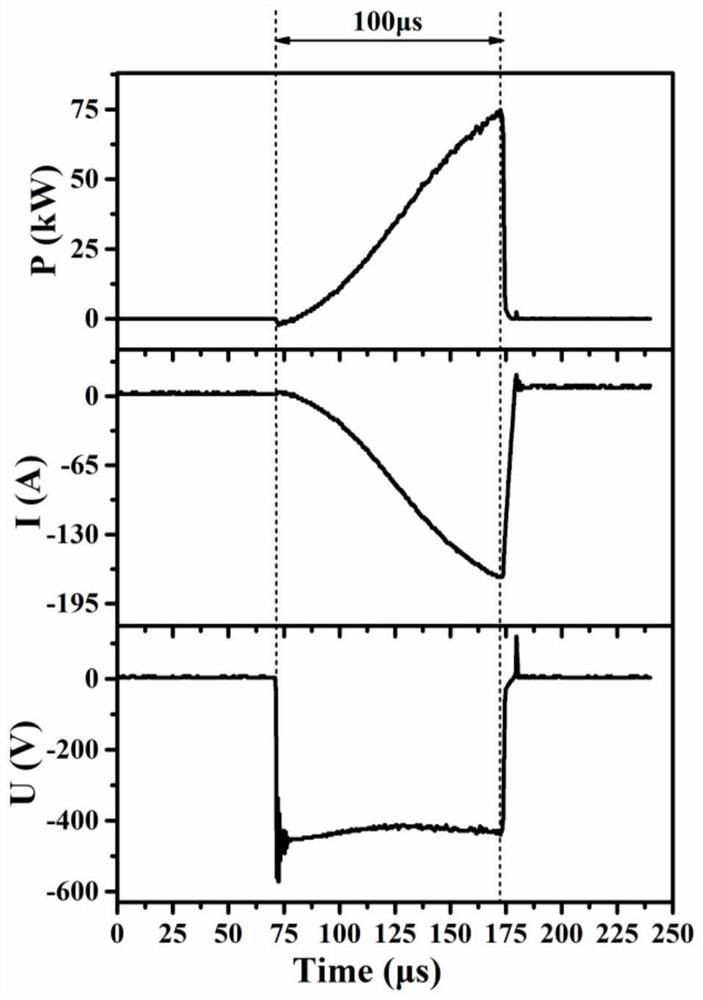

[0038]Step 3: Place the sample holder pasted with the substrate in the deposition chamber, and wait for the mechanical pump and the molecular pump to evacuate to 3×10 -5 Below Pa, set the chamber temperature to 100°C, feed 34sccm high-purity argon gas into the vacuum chamber, set the linear anode ion source current to 0.2A, and the substrate bias to -200V to etch the surface of th...

Embodiment 2

[0048] In this embodiment, the base material is TC4 titanium alloy, and the Ti on the base surface 3 AlC 2 The specific preparation steps of the MAX phase coating are as follows:

[0049] Step 1: Use 400#~2000# SiC sandpaper to polish the surface of TC4 titanium alloy in sequence, and then use diamond abrasive paste to polish for 20 minutes;

[0050] Step 2: Place the ground and polished TC4 titanium alloy substrate in acetone for 10 minutes of ultrasonic cleaning, then dry it with cold air and paste it on the sample holder with conductive adhesive for later use.

[0051] Step 3: Place the sample holder pasted with the substrate in the deposition chamber, and wait for the mechanical pump and the molecular pump to evacuate to 3×10 -5 Below Pa, set the chamber temperature to 100°C, feed 34 sccm of high-purity argon gas into the vacuum chamber, set the linear anode ion source current to 0.2A, and the substrate bias to -200V to engrave the surface of the TC4 titanium alloy subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com