Ultrafast laser grinding wheel dressing device and method based on Bessel beams

A Bessel beam and grinding wheel dressing technology, which is applied in the field of ultrafast laser grinding wheel dressing devices, can solve the problems of grinding wheel precision and efficiency, achieve high peak power density, concentrate beam energy, and improve dressing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

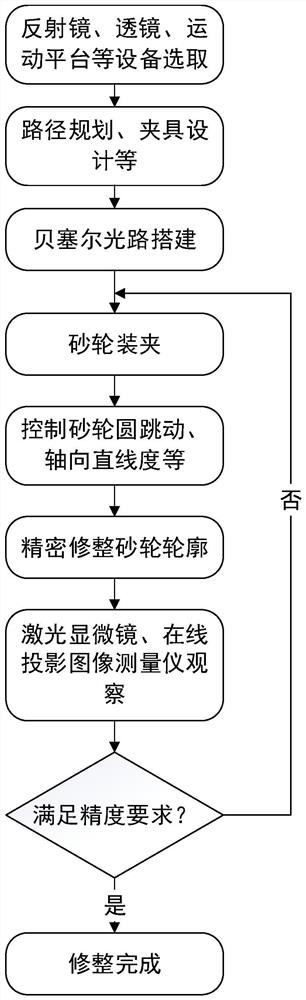

Method used

Image

Examples

Embodiment

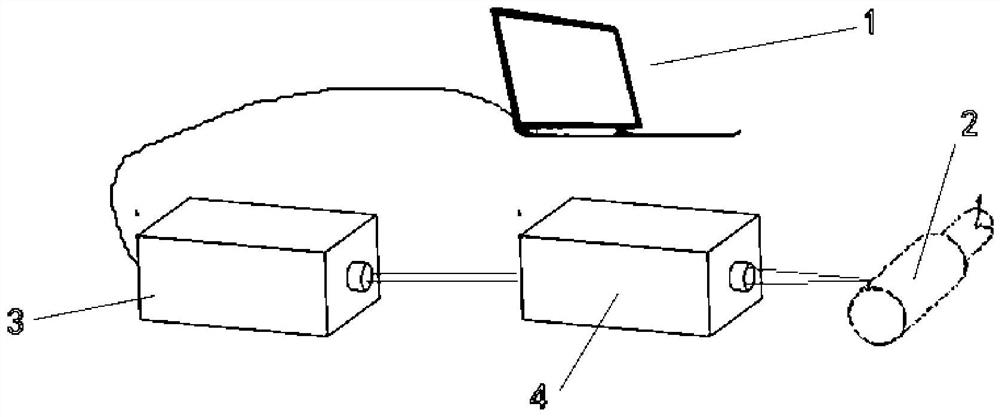

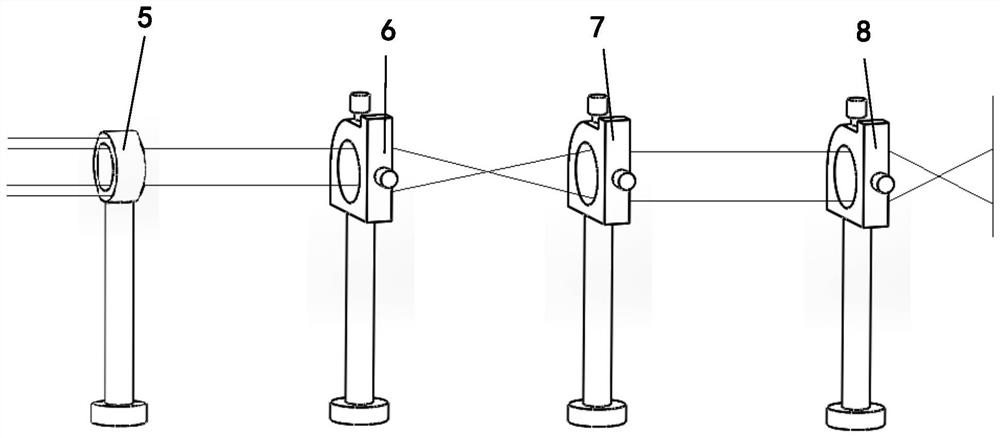

[0048] Ultrafast femtosecond pulsed laser is used, and the specific parameters are: near-infrared light with a wavelength of 800nm, a pulse width of 35fs, and a pulse frequency of 1kHz.

[0049] Install the bronze bonded diamond grinding wheel on the special fixture, adjust the position of the outer circular surface of the grinding wheel relative to the focal point of the Bessel beam spot, and scan the grinding wheel with the laser beam. Laser process parameters for tangential dressing test of diamond grinding wheel, laser power range 0.5 ~ 5W, shaft speed range 2000 ~ 5000° / min, axial scanning speed range 0.05 ~ 1mm / min, scan times The value range is 1 to 10 times, and the "Zigzag" shape trimming method is adopted. Laser power, scanning speed and number of process parameters have a great influence on the effect of grinding wheel dressing. Therefore, these process parameters are respectively subjected to single-factor tangential dressing experiments to determine the optimal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com