Production method for smelting F55 dual-phase steel in intermediate frequency furnace

A production method and technology of an intermediate frequency furnace, which are applied in the field of steelmaking, can solve the problems of low power consumption and investment in smelting time, difficulty in deoxidation, and high inclusion content, and achieve the effects of good power saving, improved smelting efficiency and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

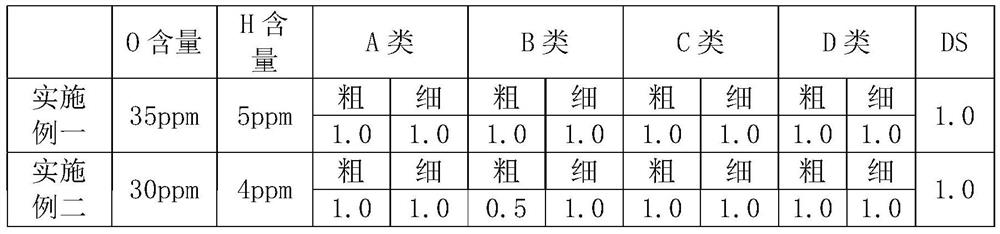

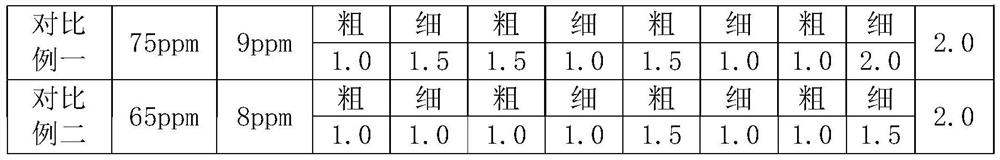

Embodiment 1

[0027] The production method of intermediate frequency furnace smelting F55 dual-phase steel comprises the following steps:

[0028] S1. Prepare molten steel according to the following mass fractions in the intermediate frequency furnace: 0.022% C, 0.5% Si, 0.45% Mn, 0.0197% P, 0.014% S, 25.0% Cr, 7.0% Ni , 3.5% Mo, 0.273% N, and the balance is Fe;

[0029] S2. Add 20kg of molten steel bottom slag into the intermediate frequency furnace and melt it; the bottom slag is composed of CaO and CaF 2 Composition, CaO and CaF 2 The mass ratio is 7:3;

[0030] S3, adding 0.5kg of Si-Ca wire after melting to carry out deoxidation;

[0031] S4. After adding the Si-Ca wire for 10 minutes, remove the slag, and then add the slag material, which is high alumina refractory brick fragments and CaF 2 Create new slag; among them, the composition of high alumina refractory bricks is Al 2 o 3 and SiO 2 , Al 2 o 3 The mass fraction is 60%, SiO 2 The quality score is 40%;

[0032] S5. Add...

Embodiment 2

[0037] The production method of intermediate frequency furnace smelting F55 dual-phase steel comprises the following steps

[0038] S1. Prepare molten steel according to the following mass fractions in the intermediate frequency furnace: 0.022% C, 0.5% Si, 0.45% Mn, 0.0197% P, 0.014% S, 25.0% Cr, 7.0% Ni , 3.5% Mo, 0.273% N, and the balance is Fe;

[0039] S2. Add 30kg of bottom slag to the intermediate frequency furnace and melt it; the bottom slag is composed of CaO and CaF 2 Composition, CaO and CaF 2 The mass ratio is 7:3;

[0040] S3, adding 2kg of Si-Ca wire after melting to carry out deoxidation;

[0041] S4. After adding the Si-Ca wire for 10 minutes, remove the slag, and then add the slag material, which is high alumina refractory brick fragments and CaF 2 Create new slag; among them, the composition of high alumina refractory bricks is Al 2 o 3 and SiO 2 , Al 2 o 3 The mass fraction is 60%, SiO 2 The quality score is 40%;

[0042] S5. Add the deoxidizer of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com