Ionization modified ethylene-acrylic acid copolymer and preparation method thereof, and ionic polymer intermediate membrane and application thereof

A technology of ionic polymers and copolymers, applied in chemical instruments and methods, films/sheets without carriers, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the present invention, the preparation method of the ion-type polymer intermediate film comprises the following steps: extruding, stretching, pelletizing and flow-forming the ionized modified ethylene-acrylic acid copolymer described in the above technical solution in sequence film extension to obtain the ionic polymer intermediate film.

[0041] In the present invention, the thickness of the ionomer intermediate film is preferably 0.35-2.5 mm, more preferably 0.75-1.5 mm.

[0042] The present invention also provides the application of the ionic polymer intermediate film described in the above technical solution in laminated safety glass.

[0043]The present invention also provides a laminated safety glass. The laminated safety glass comprises the ionomer interlayer and a glass layer, and the glass layer is arranged on both sides of the ionomer interlayer.

[0044] In order to further illustrate the present invention, the ionized modified ethylene-acrylic acid copol...

Embodiment 1

[0054] Get commercially available ethylene-methacrylic acid copolymer, wherein the content of methacrylic acid structural unit is 15wt%, makes intermediate film 1 after forming film through extrusion casting process, the thickness of gained intermediate film 1 is 1.2mm, pulls The tensile strength is 23.7Mpa. Combine the above-mentioned interlayer film 1 with two pieces of glass, and then use vacuum bag degassing to prepare laminated safety glass through a lamination furnace process to obtain sample 1, and further test the light transmittance, haze, impact resistance and hydrothermal resistance of sample 1 , and the results are listed in Table 1.

[0055] Get above-mentioned ethylene-methacrylic acid copolymer, wherein the content of methacrylic acid structural unit is 15wt%, add zinc oxide powder (the amount of the added zinc ion is 15% of the molar content of carboxylic acid functional group), place in kneader, Mix at 20°C for 0.5h, heat up to 115°C for ionization reaction, ...

Embodiment 2

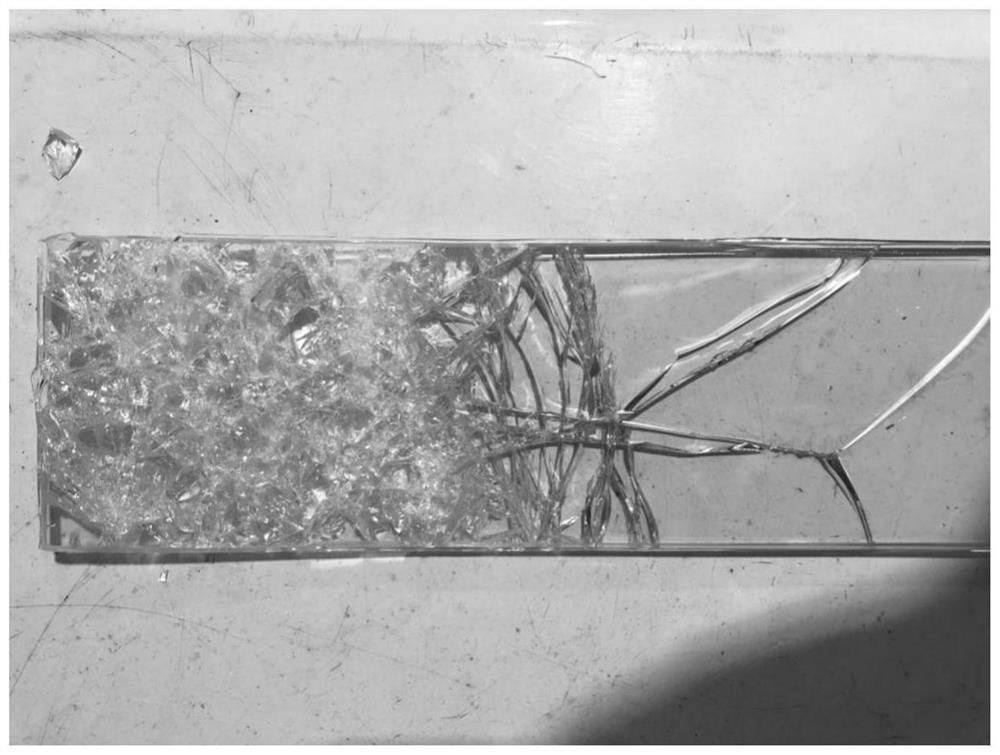

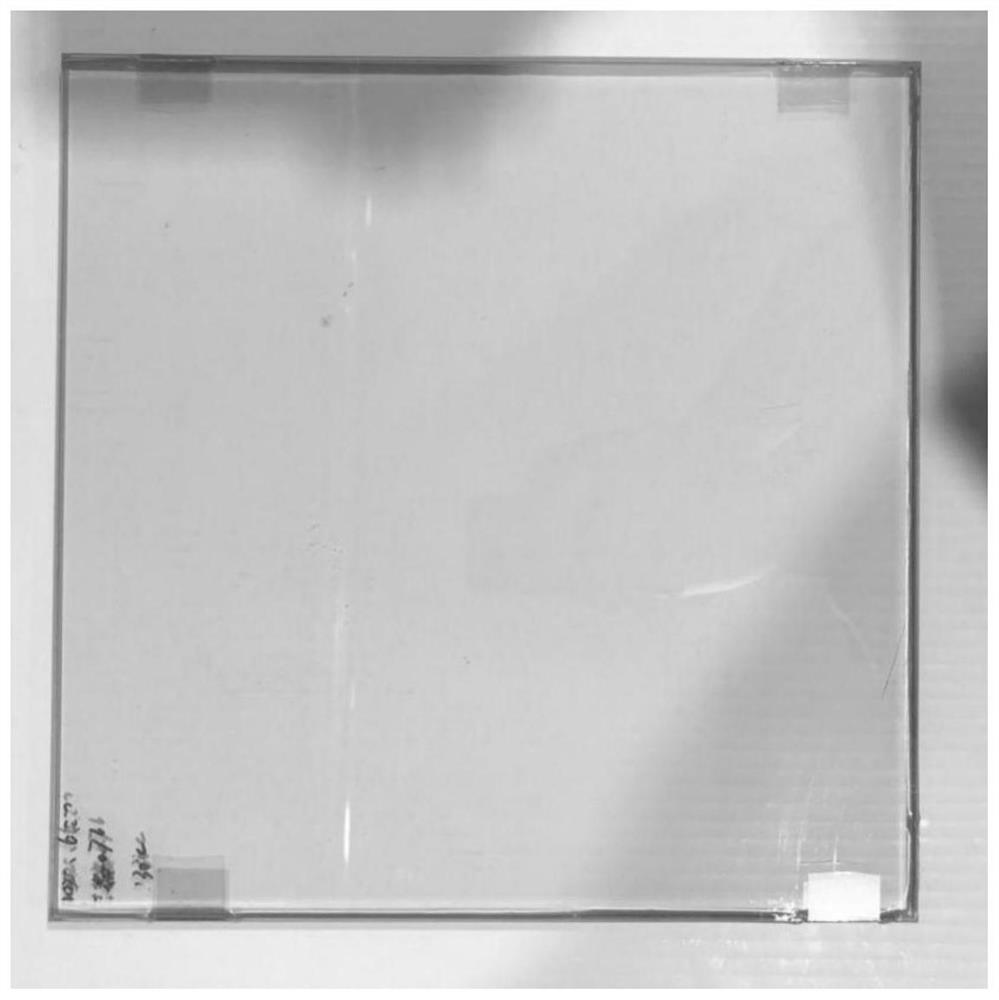

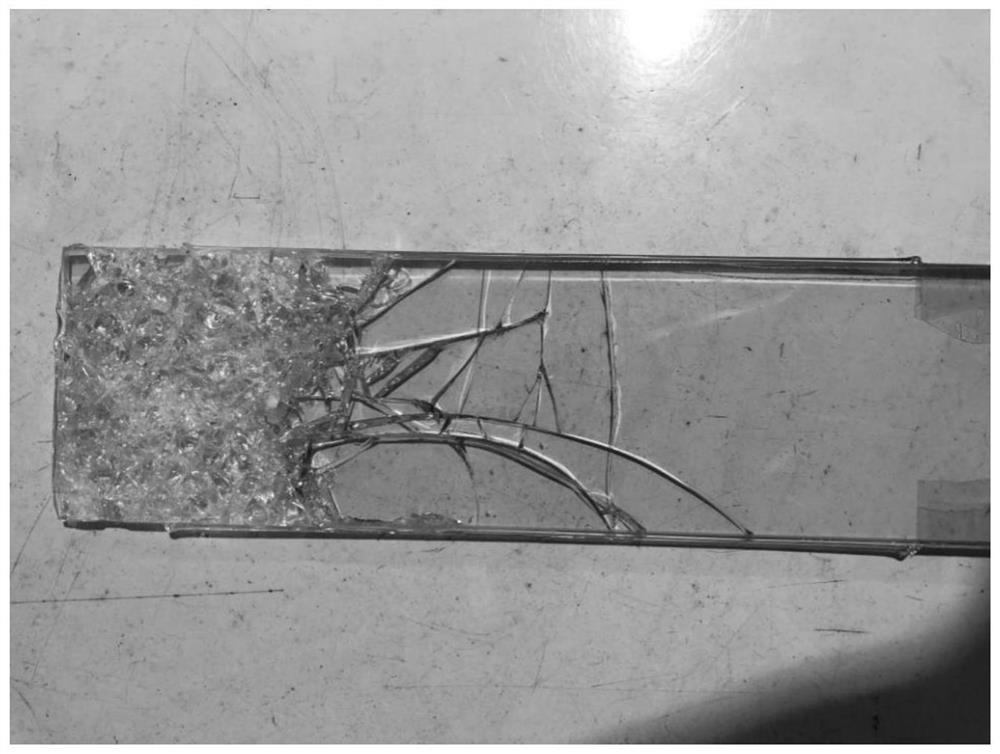

[0071] Get commercially available ethylene-methacrylic acid copolymer, wherein the content of methacrylic acid structural unit is 7.0wt%, add zinc acetylacetonate (the amount of zinc acetylacetonate added is 5% of the molar content of carboxylic acid functional group), place kneading In the machine, mix at 20°C for 0.5h, heat up to 140°C and melt, add zinc hydroxide powder (the amount of zinc ions added is 30% of the molar content of carboxylic acid functional groups), carry out ionization reaction, react for 5h, extrude and pelletize , after being further formed into a film by extrusion casting process, the thickness of the obtained interlayer film is 1.2mm, and the tensile strength is 31.1MPa. After being combined with two pieces of glass, the laminated safety glass is prepared by vacuum bag degassing and lamination furnace process. , the sample is smooth and free of bubbles, its light transmittance reaches 90.4%, and its haze is 1.05%. figure 1 This is a photo of the impact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com