Self-healing gel leakage-proof agent while drilling under covalent bond-non-covalent bond composite action and preparation method and application thereof

A non-covalent bond and composite effect technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of weak pressure bearing capacity, low applicable temperature, and weak bonding of self-healing gel plugging materials and other problems to achieve the effects of saving drilling time, strong pressure bearing capacity, excellent mechanical properties and healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

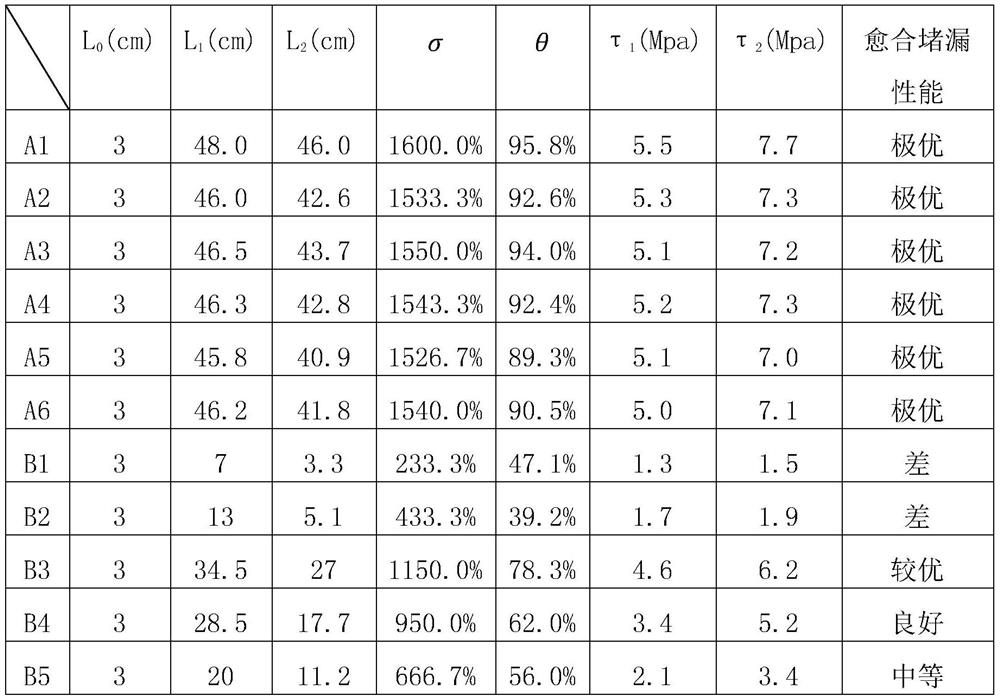

Embodiment 1

[0055] A covalent-non-covalent bond self-healing gel plugging agent, comprising the following raw materials in parts by weight, 28 parts of the first comonomer, 15 parts of the second comonomer, 0.2 part of the initiator, the first 3.2 parts of a linking agent, 2.5 parts of a second cross-linking agent, 2.3 parts of a hydrogen bond enhancer, and 48.8 parts of an aqueous acetic acid solution with a concentration of 0.5 mol / L.

[0056] Among them, the first comonomer is a combination of sodium alginate and xylan, and the mass ratio of sodium alginate and xylan is 1:5; the second comonomer is polyvinyl alcohol; the initiator is oxidation- A reduction initiator, the oxidant in the initiator is potassium persulfate, the reducing agent is sodium bisulfite, and the mass ratio of potassium persulfate to sodium bisulfite is 0.6:1; the second crosslinking agent is borax; the first crosslinking agent The agent is a combination of glutaraldehyde and diisocyanate, and the mass ratio of glu...

Embodiment 2

[0066] A covalent-non-covalent bond self-healing gel plugging agent, comprising the following raw materials in parts by weight, 28 parts of the first comonomer, 15 parts of the second comonomer, 0.2 part of the initiator, the first 2.6 parts of a linking agent, 2.3 parts of a second crosslinking agent, 2 parts of a hydrogen bond enhancer, and 49.9 parts of an aqueous acetic acid solution with a concentration of 0.4 mol / L.

[0067] Wherein, the first comonomer is xylan; the second comonomer is polyvinyl alcohol; the initiator is an oxidation-reduction initiator, the oxidizing agent in the initiator is potassium persulfate, and the reducing agent is sodium bisulfite , the mass ratio of potassium persulfate and sodium bisulfite is 0.6: 1; the second crosslinking agent is borax; the first crosslinking agent is the combination of glutaraldehyde and diisocyanate, and the mass ratio of glutaraldehyde and diisocyanate is 3:1; the hydrogen bond enhancer is melamine.

[0068] The prepa...

Embodiment 3

[0070] A covalent-non-covalent bond self-healing gel plugging agent, comprising the following raw materials in parts by weight, 20 parts of the first comonomer, 11 parts of the second comonomer, 0.2 part of the initiator, the first 2.5 parts of a linking agent, 2.3 parts of a second crosslinking agent, 2 parts of a hydrogen bond enhancer, and 62 parts of an aqueous acetic acid solution with a concentration of 0.3 mol / L.

[0071] Wherein, the first comonomer is a combination of chitosan and xylan, and the mass ratio of chitosan and xylan is 1:2.5; the second comonomer is a combination of polyvinyl alcohol and dipropylene glycol , the mass ratio of polyvinyl alcohol and dipropylene glycol is 2:1, the initiator is an oxidation-reduction initiator, the oxidizing agent in the initiator is ammonium persulfate, and the reducing agent is sodium bisulfite, potassium persulfate and bisulfite The mass ratio of sodium is 0.5:1; the second crosslinking agent is borax; the first crosslinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com