Manufacture of ball of ball valve

A manufacturing method and ball plug technology, applied in the field of ball plug manufacturing of ball valves, can solve problems such as high difficulty, poor structural strength, difficulty, etc., and achieve the effects of low processing difficulty, rapid manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific structure of the present invention is given in detail by the following examples and accompanying drawings. The specific structure, features and functions of the method for manufacturing the ball plug of the ball valve according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

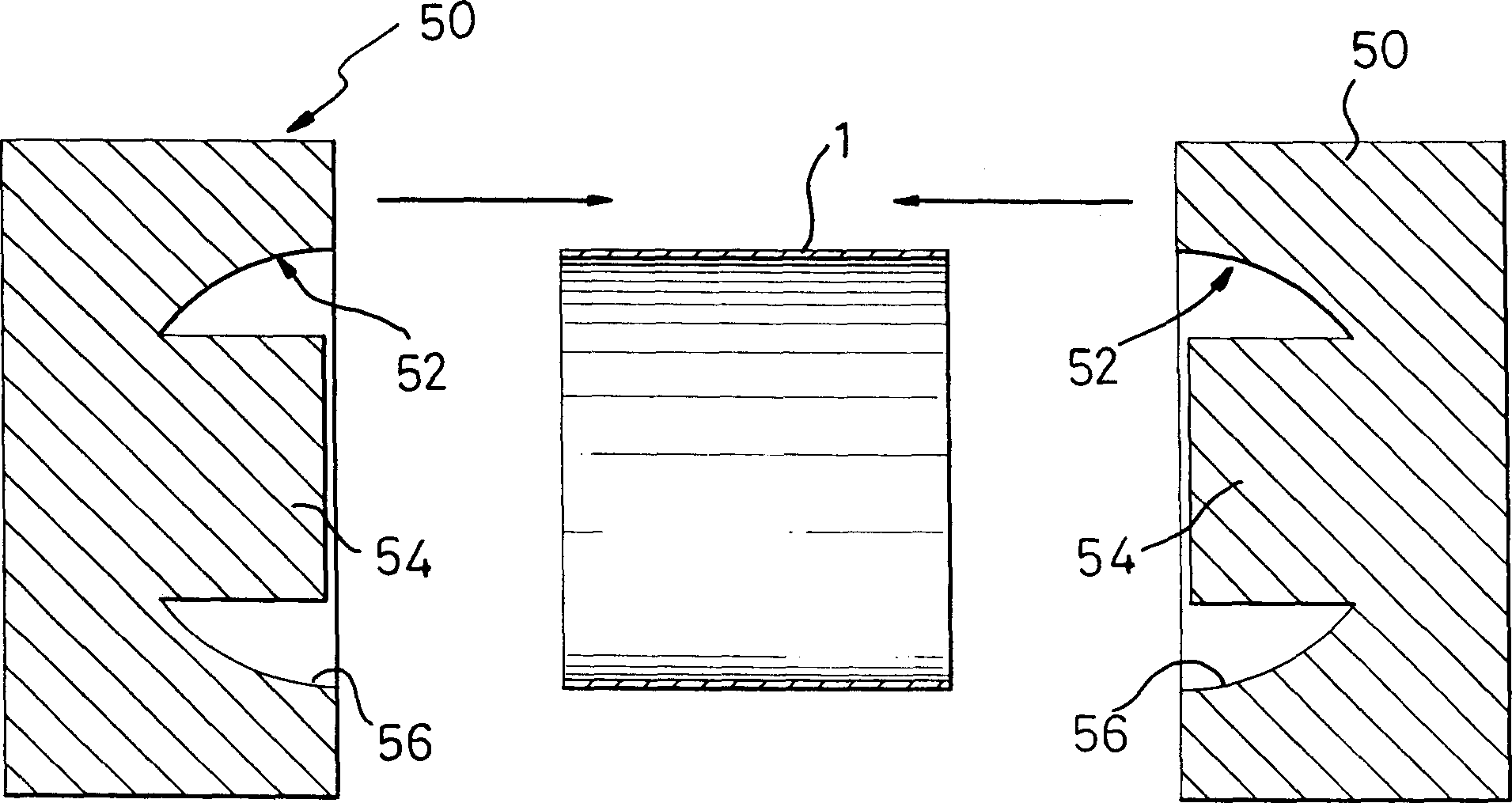

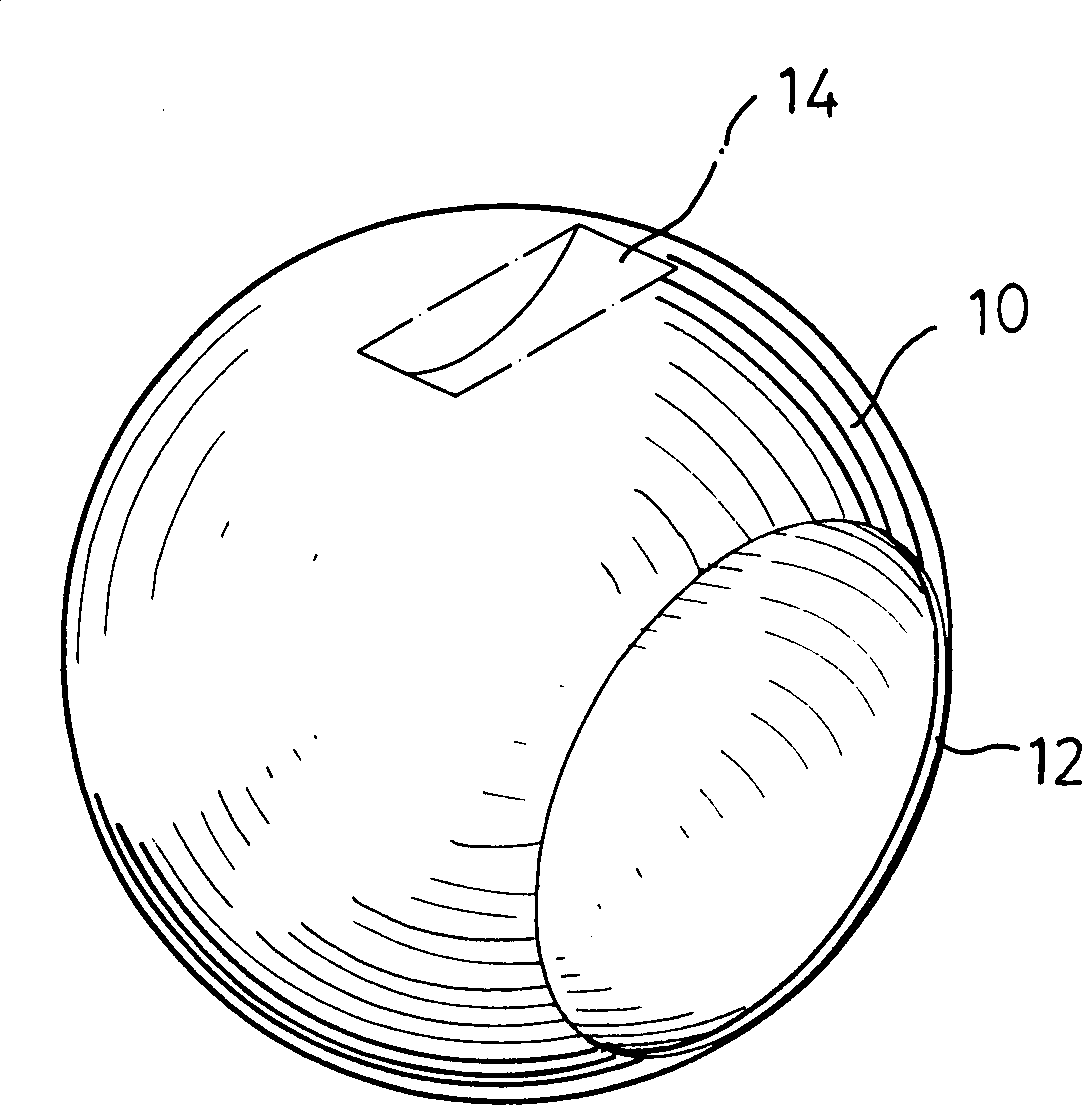

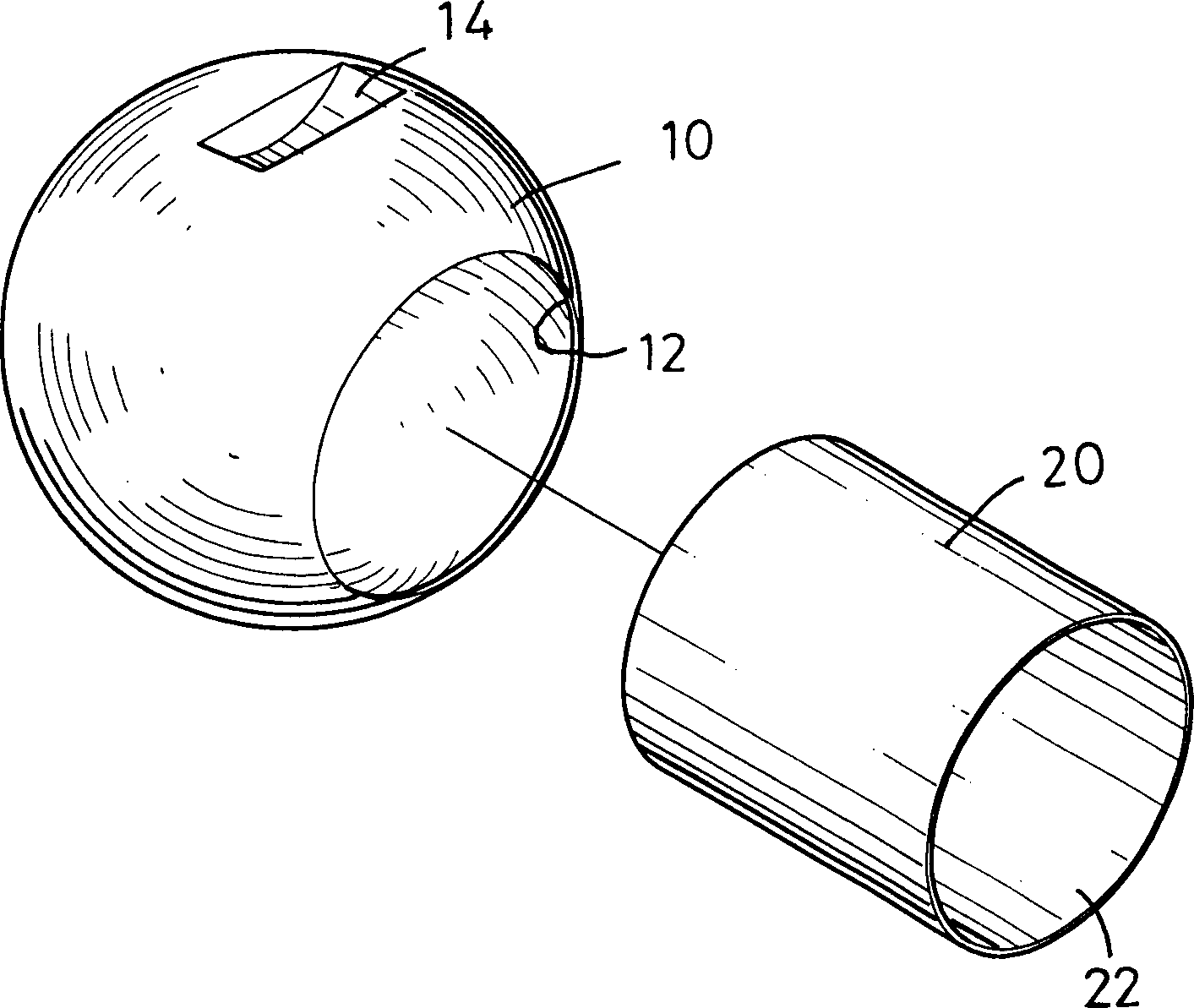

[0031] see figure 1 , figure 2 As shown, the manufacturing method of the ball plug of the ball valve of the present invention is an innovative manufacturing method applied to the ball plug of the ball valve. First, a circular pipe 1 with an appropriate specification and shape is selected. The circular pipe 1 can be a stainless steel pipe Or metal pipes such as copper pipes, its caliber and pipe length can be adjusted slightly according to the difference in material and thickness, as long as the circular pipe 1 can be stamped into a spherical shell 10 with circular openings 12 on both sides, generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com