A kind of multiple non-covalent bond synergistic self-healing gel plugging agent and its preparation and application

A technology of non-covalent bonding and gelation, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of plugging material formula and preparation process complex, weak pressure bearing capacity, low applicable temperature, etc. Achieve good healing effect, strong pressure bearing capacity and high applicable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

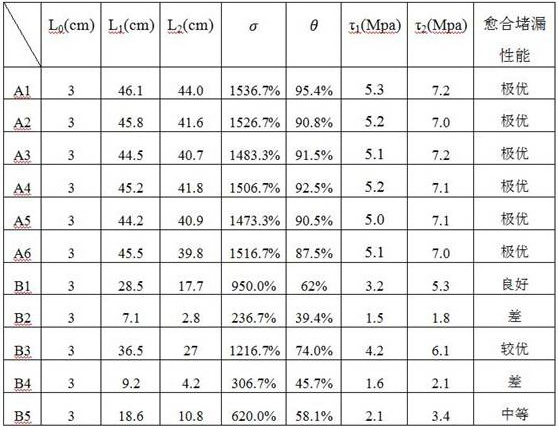

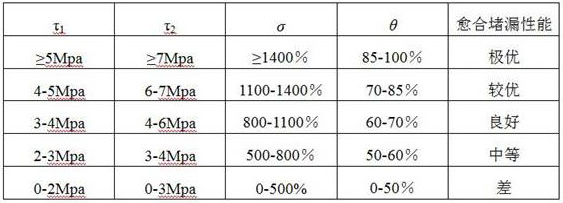

Examples

Embodiment 1

[0066] A non-covalent bond synergistic self-healing plug, including 27 parts by weight of the raw material, 27 parts of the first copolymerized reaction monomer, 23 parts of the second copolymerizer, 3 surfactants, 0.2 initiator 2.4 parts of the first crosslinking agent, 2.8 parts of the second crosslinking agent, 0.15 parts of the promoter, 41.45 parts of a sodium chloride solution of 0.9 mol / L.

[0067] Among them, the first copolymerization monomer is a combination of xanthan gum and chitosan, which is a mass ratio of xanthan gum and chitosan is 3: 1; hydrophilic monomer in the second copolymerized monomer is acrylamide. The hydrophobic monomer is a stearate of methacrylate, the mass ratio of hydrophilic monomer and the hydrophobic monomer is 12: 1; the surfactant uses sodium sulfate sulfate; the initiator is selected from potassium sulfate; The combination of the calcium sulfate and the mexyphenol of dihydrate, the mass ratio of calcium sulfate and the amphidenphenol is 2: 1...

Embodiment 2

[0076] A non-covalent bond synergistic healing gel plug, including 26 parts by weight of the raw material, 1000 copolymerized monomer, 17 parts of the second copolymerizer, 1 surfactant, 0.2 initiator 2.3 parts of the first crosslinking agent, 2.3 parts of the second crosslinking agent, 0.17 parts of the promoter, 51.03 parts of the aqueous solution of 0.9 mol / L of the sodium chloride solution.

[0077] Among them, the first copolymerization monomer is a combination of sodium alginate and xanthan gum, which is a mass ratio of sodium alginate and xanthan gum is 1: 2; the hydrophilic monomer in the second copolymerized monomer is acrylamide. Combination with methacrylic acid, the mass ratio of acrylamide and methacrylic acid is 1: 1, the hydrophobic monomer is a stearate of methacrylate, the mass ratio of hydrophilic monomer and the hydrophobic monomer is 13: 1; surface The active agent uses sodium dodecyl benzene sulfonate; the initiator uses ammonium sulfate; the first crosslink...

Embodiment 3

[0080] A non-covalent bond synergistic healing gel plug, including 26 parts by weight of the raw material, 1000 copolymerized monomer, 17 parts of the second copolymerizer, 1 surfactant, 0.2 initiator 2.3 parts of the first crosslinking agent, 2.3 parts of the second crosslinking agent, 0.17 parts of the promoter, 51.03 parts of the aqueous solution of 0.9 mol / L of the sodium chloride solution.

[0081] Among them, the first copolymerization monomer is a combination of sodium alginate and xanthan gum, which is a mass ratio of sodium alginate and xanthan gum is 1: 2; the hydrophilic monomer in the second copolymerized monomer is acrylamide. With the combination of methacrylic acid, the mass ratio of acrylamide and methacrylic acid is 1: 1.5, the hydrophobic monomer is a hexadalkyl acrylate, the mass ratio of hydrophilic monomer and the hydrophobic monomer is 11: 1; Surfactants are used in dodecyl sulfate; the initiator is selected from potassium sulfate; the first cross-sulfate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com