Ultra-high performance concrete based on composite cementing material system

A composite cementitious material, ultra-high performance technology, applied in the field of building materials, can solve problems such as inability to deploy design, complicated preparation process, slow down the progress of the project, etc., to achieve the effect of rapid hardening and early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

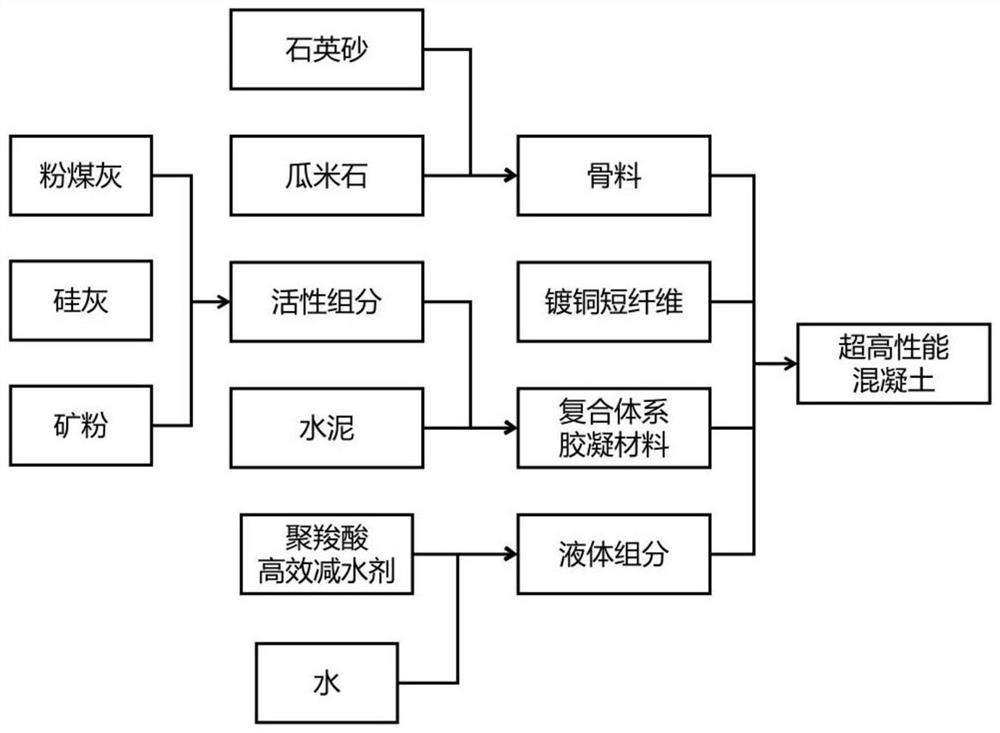

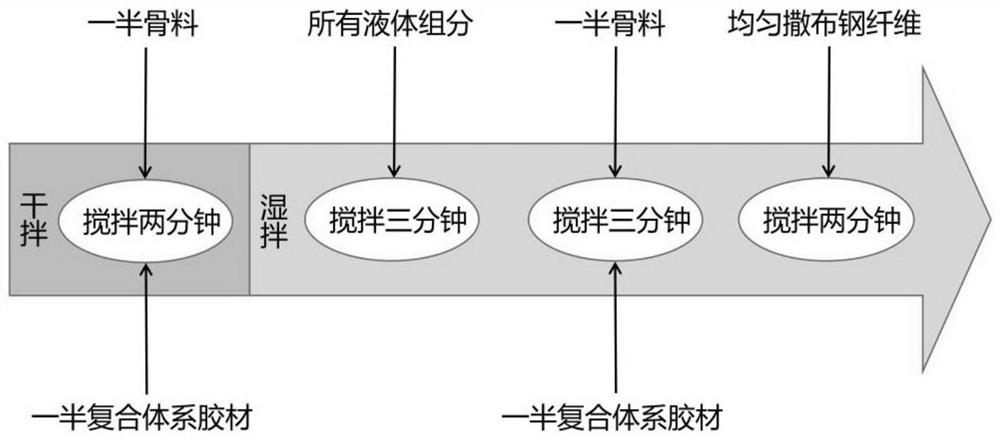

[0036] see figure 1 As shown, select raw materials according to the following list: P·Ⅱ 52.5 Portland cement, 42.5 sulphoaluminate cement, fly ash microbeads (active material), silica fume (active material), mineral powder (active material), Quartz sand, copper-plated short fibers, polycarboxylate superplasticizer, water.

[0037] Among them, P·Ⅱ 52.5 Portland cement, 42.5 sulfoaluminate cement, fly ash microbeads, silica fume, and mineral powder are the components of the composite cementitious material system, according to SiO 2 :Al 2 o 3 The molar ratio is 7.6, SiO 2 : Na 2 The molar ratio of O is 132.5, SiO 2 : Molar ratio of CaO is 1.1, SiO 2 : SO 3 The molar ratio was 169.9, and the material was weighed to prepare a gelled material.

[0038] Water is weighed according to the water-cement ratio of 0.18, and quartz sand is weighed according to 90% of the mass of the cementitious material. The mass ratio of fine sand: medium sand: coarse sand is 2:4:3, and copper-pla...

Embodiment 2

[0051] see figure 1 As shown, select raw materials according to the following list: P·Ⅱ 52.5 Portland cement, 42.5 sulphoaluminate cement, fly ash microbeads (active material), silica fume (active material), mineral powder (active material), Quartz sand, copper-plated short fibers, polycarboxylate superplasticizer, water.

[0052] Among them, P·Ⅱ 52.5 Portland cement, 42.5 sulfoaluminate cement, fly ash microbeads, silica fume, and mineral powder are the components of the composite cementitious material system, according to SiO 2 :Al 2 o 3 The molar ratio is 6.4, SiO 2 : Na 2 The molar ratio of O is 121.4, SiO 2 : The molar ratio of CaO is 1.1, SiO 2 : SO 3 The molar ratio was 82.2, the material was weighed and the gelled material was prepared.

[0053] Water is weighed according to the water-cement ratio of 0.18, and quartz sand is weighed according to the mass of 90% of the cementitious material, of which the mass ratio of fine sand: medium sand: coarse sand is 2:4:3...

Embodiment 3

[0077] see figure 1 As shown, select raw materials according to the following list: according to P·Ⅱ 52.5 Portland cement, 42.5 sulphoaluminate cement, fly ash microbeads (active material), silica fume (active material), mineral powder (active material) , quartz sand, melon stone, copper-plated short fiber, polycarboxylate superplasticizer, water.

[0078] Among them, P·Ⅱ 52.5 Portland cement, 42.5 sulfoaluminate cement, fly ash microbeads, silica fume, and mineral powder are the components of the composite cementitious material system, according to SiO 2 :Al 2 o 3 The molar ratio of SiO is 8.3, 2 : Na 2 The molar ratio of O is 203.8, SiO 2 : The molar ratio of CaO is 0.9, SiO 2 : SO 3 The molar ratio is 281.7 Weigh the material and prepare the gelled material.

[0079] Water is weighed according to the water-cement ratio of 0.19, and quartz sand is weighed according to the mass of 78% of the cementitious material, wherein the mass ratio of fine sand: medium sand: coar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com