Fluoride-doped high-capacity Gd-Mg-Ni-based composite hydrogen storage material and preparation method thereof

A hydrogen storage material and high-capacity technology, applied in the field of hydrogen storage materials, can solve the problems of slow kinetics and practical application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

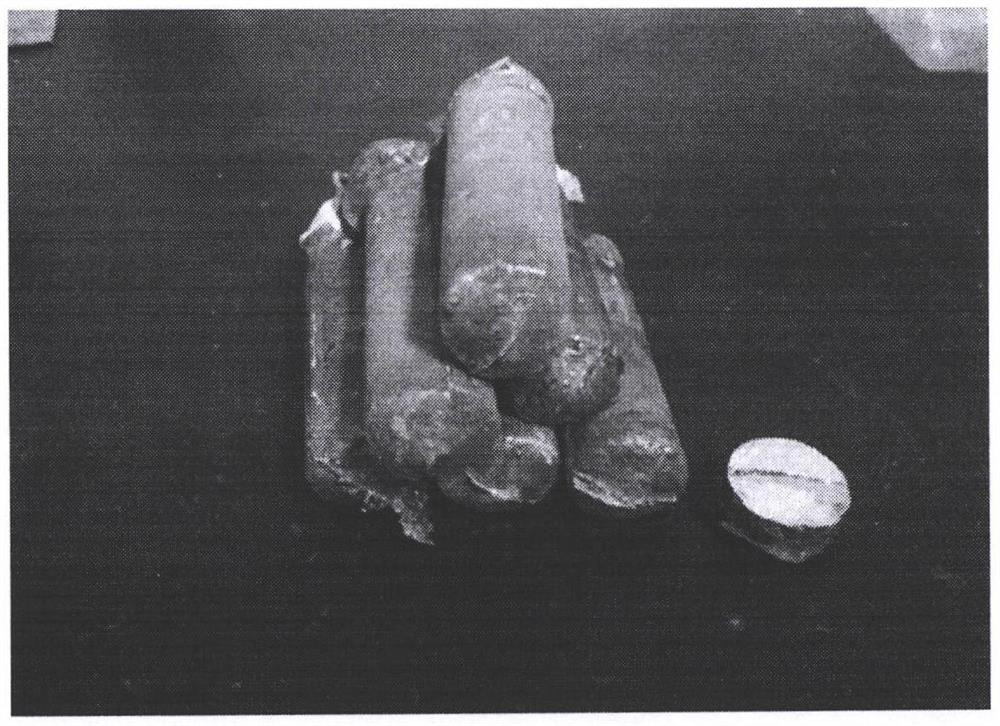

Image

Examples

preparation example Construction

[0019] The preparation method of high-capacity hydrogen storage material in the present invention comprises the following steps:

[0020] a. Ingredients: Gd according to the chemical formula x Mg 100-x-y Ni y Carry out the matching ratio, in the formula, 1≤x≤9, 5≤y≤20. Since the metal will be burned during the smelting process, 5wt.% of rare earth elements and 8wt.% of Mg should be added to reduce the amount of burning loss. The metal purity of the raw material is >99.5%.

[0021] b. Preparation of matrix alloy: Place the prepared raw materials evenly in the crucible, then turn on the power, start the vacuum induction melting furnace, and evacuate to 1×10 -2 -5×10 -5 Pa, through 0.01-0.1MPa helium as protective gas. The metal is heated and melted, kept warm for 15 minutes, then poured into a mold, and then slowly cooled with the furnace to obtain an alloy ingot with a diameter of 30mm.

[0022] c. Mechanical ball milling treatment: the alloy ingot obtained by vacuum ind...

Embodiment 1

[0025] Example 1: Gd 5 Mg 85 Ni 10 +2wt.%TiF 3

Embodiment 2

[0026] Example 2: Gd 5 Mg 85 Ni 10 +5wt.%TiF 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com