Beryllium-copper alloy battery probe for new energy automobile and processing technology thereof

A new energy vehicle, beryllium-copper alloy technology, applied in metal material coating technology, secondary batteries, battery pack components, etc., can solve problems such as poor conductivity, unstable battery power supply, etc., to improve strength and guarantee The effect of power supply stability and enhanced low temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a beryllium-copper alloy battery probe for new energy vehicles, which comprises: 0.20% beryllium, 0.08% zirconium, 1.40% nickel, 0.17% surface treatment agent, and the sum of impurities < 0.05%. , and the rest is copper; the surface treatment agent includes: 9.60% silver nitrate, 9.40% zinc nitrate, 49.40% absolute ethanol, 31.60% deionized water according to weight percentage;

[0027] A processing technology for a beryllium-copper alloy battery probe for a new energy vehicle, the specific processing steps are as follows:

[0028] Step 1: according to the above weight ratio, weigh silver nitrate, zinc nitrate, absolute ethanol, deionized water in beryllium, zirconium, nickel, copper and surface treatment agent raw materials;

[0029] Step 2: Melting the beryllium, zirconium, nickel, and copper in step 1, casting them into billets, and then making the billets into copper alloy foils;

[0030] Step 3: Blending silver nitrate, zinc nitrate, absolut...

Embodiment 2

[0036] Different from Example 1, it includes: 0.60% beryllium, 0.12% zirconium, 2.20% nickel, 0.21% surface treatment agent, the sum of impurities < 0.05%, and the rest is copper; the surface treatment The agent includes: 10.60% silver nitrate, 10.40% zinc nitrate, 50.80% absolute ethanol, 28.20% deionized water according to weight percentage.

Embodiment 3

[0038]The difference from Examples 1-2 is that it includes: 0.40% beryllium, 0.10% zirconium, 1.80% nickel, 0.19% surface treatment agent, the sum of impurities < 0.05%, and the rest is copper; The surface treatment agent includes: 10.10% silver nitrate, 9.90% zinc nitrate, 50.10% absolute ethanol, 29.90% deionized water according to weight percentage.

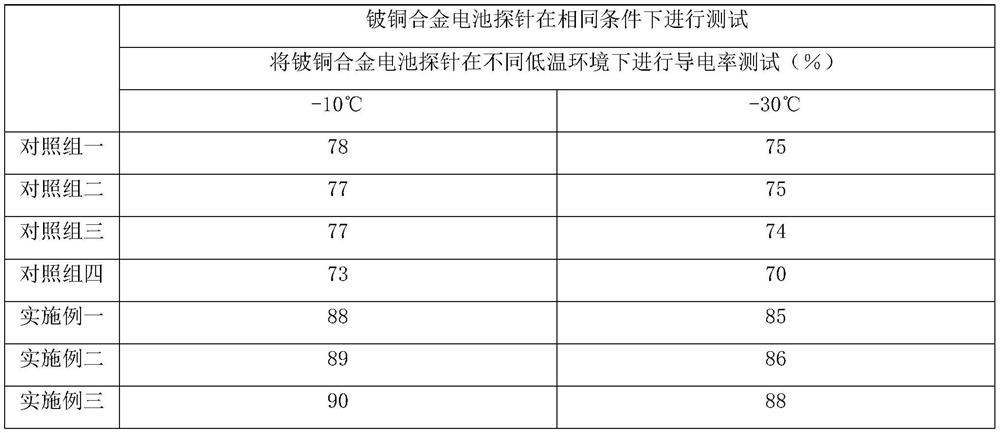

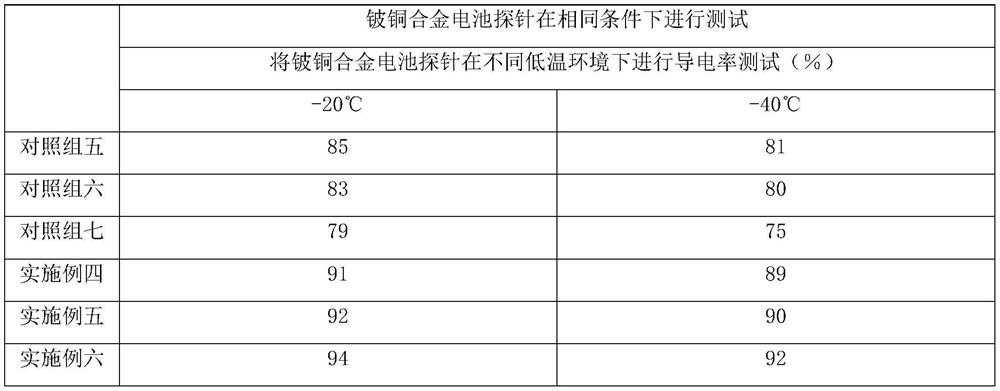

[0039] Take respectively the beryllium-copper alloy battery probes prepared in the above-mentioned embodiments 1-3, the beryllium-copper alloy battery probes of the control group one, the beryllium-copper alloy battery probes of the control group two, and the beryllium-copper alloy battery probes of the control group three. The beryllium-copper alloy battery probe of needle and control group four, the beryllium-copper alloy battery probe of control group one has no zirconium compared with embodiment three, and the beryllium-copper alloy battery probe of control group two has no nitric acid compared with embodiment three Silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com