Fireproof thermal insulation polyphenyl granule, preparation method and fireproof thermal insulation mortar

A technology of fireproof and thermal insulation mortar and polystyrene particles, which is applied in the field of fireproof and thermal insulation polystyrene particles, preparation, and fireproof thermal insulation mortar. , The effect of improving compactness and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1~12

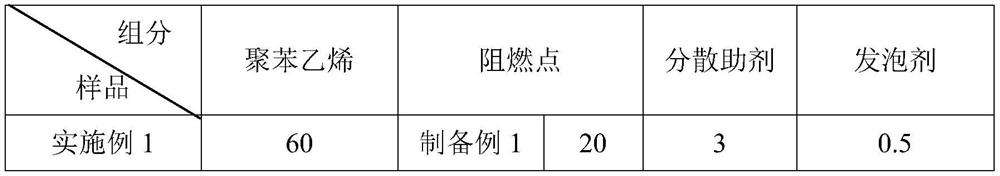

[0034] As shown in Table 1, the main difference between Preparation Examples 1-12 lies in the different ratios of flame retardant points.

[0035] A kind of flame retardant point, adopts following method to prepare:

[0036] S1: Preparation of aramid pulp:

[0037] 1) immersing 100kg of aramid pulp in 25kg of a polyvinyl alcohol aqueous solution with a mass concentration of 5%, to obtain an immersion solution;

[0038] 2) Put the impregnating liquid into a screw extrusion kneader, stir and shear at 80°C for 30 minutes to prepare aramid pulp;

[0039] S2: Preparation of flame retardant point:

[0040] 1) Ingredients: According to the content in Table 1, weigh polystyrene, inorganic flame retardant, aramid pulp, dispersant and foaming agent; the dispersant is selected from nano-calcium carbonate; the foaming agent is selected from supercritical CO 2 ;

[0041] 2) Extrusion: Mix polystyrene, inorganic flame retardant, and dispersant evenly in a blender, then inject the mixture ...

preparation example 13

[0047] A kind of flame retardant point, the difference between this preparation example and preparation example 7 is that the composition of the aramid pulp is different, the polyvinyl alcohol in the aramid pulp is replaced by acetone, and the impregnating liquid is put into the screw extrusion kneader during the preparation stage , stirring and shearing for 40 min at 40° C.; the rest of the preparation method was the same as that of Preparation Example 7.

preparation example 14

[0049] A kind of flame retardant point, the difference between this preparation example and preparation example 7 is that the composition of the aramid pulp is different, the polyvinyl alcohol in the aramid pulp is replaced with polyethylene glycol, and the mass concentration is 20% polyethylene glycol. Alcoholic aqueous solution, all the other preparation methods are the same as in Preparation Example 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com