High-gloss self-curing epoxy resin as well as preparation method and application thereof

An epoxy resin, self-curing technology, applied in the field of powder coatings, can solve the problems of low product gloss, poor batch stability of powder coatings, poor curing impact performance, etc., achieve high gloss of coating film, solve gloss and leveling The performance is not ideal, the effect of high leveling level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

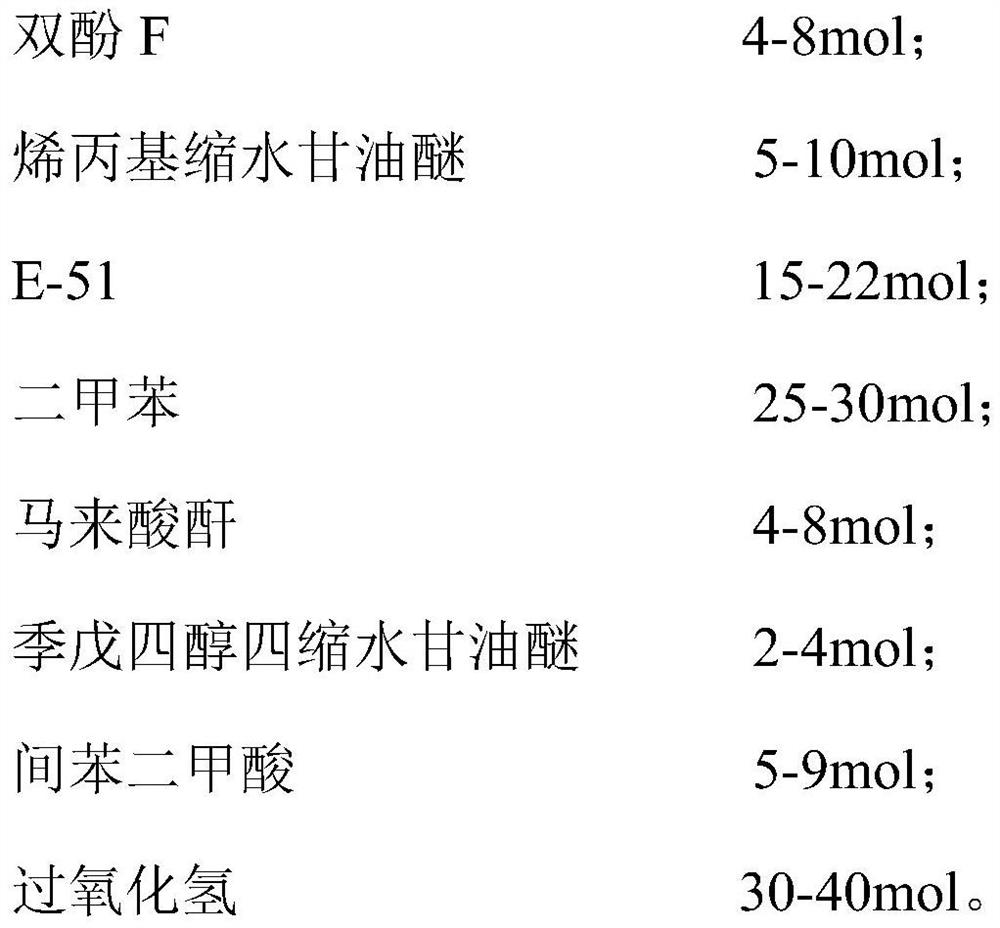

[0027] The high-gloss self-curing epoxy resin described in this embodiment, its preparation raw material comprises the component of following molar weight:

[0028]

[0029] Sodium tungstate: benzyltrimethylammonium chloride = 1:0.2, accounting for 0.2wt% of the mass of bisphenol F.

[0030] The preparation method of high-gloss self-curing epoxy resin described in the present embodiment may further comprise the steps:

[0031] (1) Take the bisphenol F, allyl glycidyl ether, E-51, xylene and ring-opening polymerization catalyst in the formula amount and add them to the reactor, start stirring, gradually heat up to 90°C, and then carry out the heat preservation reaction;

[0032] (2) With the amount of free bisphenol F in the liquid chromatography detection system, when the amount of free bisphenol F in the system is lower than 1%, add the described maleic anhydride and pentaerythritol of formula amount in the reactor at this moment Tetraglycidyl ether, heated up to 110°C fo...

Embodiment 2

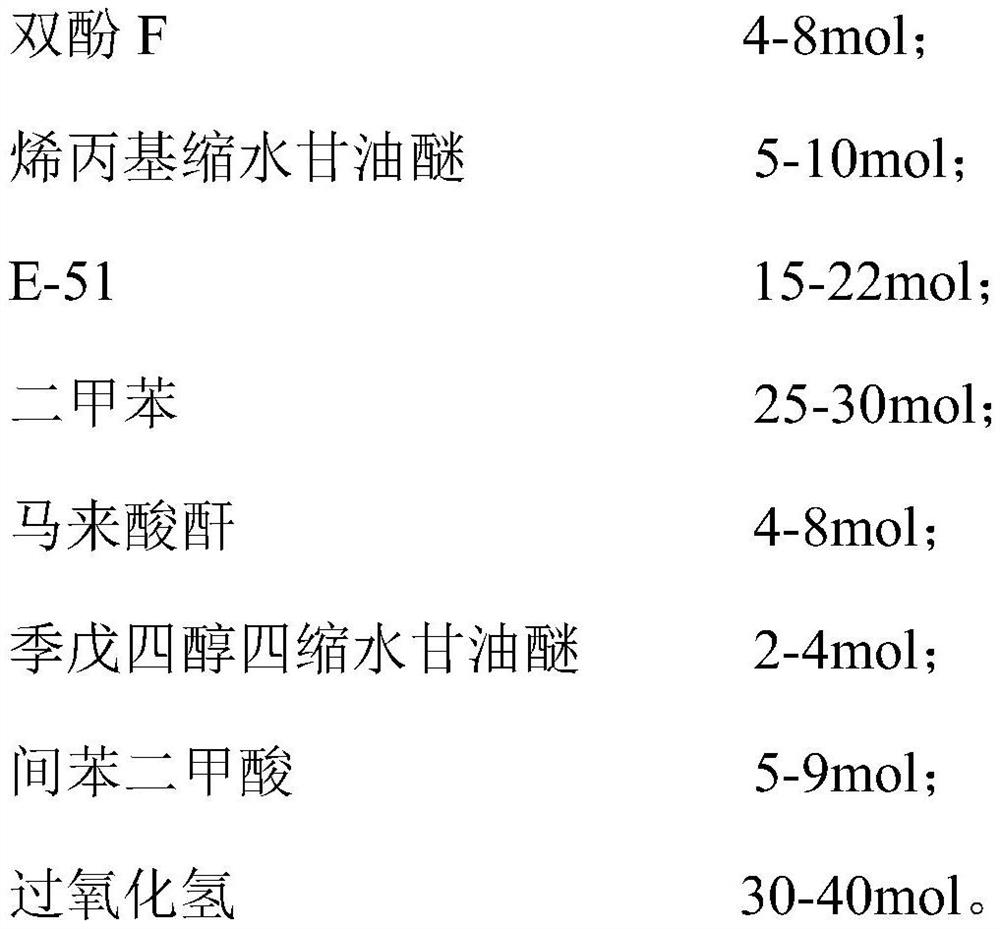

[0039] The high-gloss self-curing epoxy resin described in this embodiment, its preparation raw material comprises the component of following molar weight:

[0040]

[0041] Sodium tungstate: benzyltrimethylammonium chloride = 1:0.4, accounting for 0.5 wt% of the mass of bisphenol F.

[0042] The preparation method of high-gloss self-curing epoxy resin described in the present embodiment may further comprise the steps:

[0043] (1) Take the bisphenol F, allyl glycidyl ether, E-51, xylene and ring-opening polymerization catalyst in the formula amount and add them into the reaction kettle, start stirring, gradually heat up to 95°C, and then carry out the heat preservation reaction;

[0044] (2) With the amount of free bisphenol F in the liquid chromatography detection system, when the amount of free bisphenol F in the system is lower than 1%, add the described maleic anhydride and pentaerythritol of formula amount in the reactor at this moment Tetraglycidyl ether, heat up to...

Embodiment 3

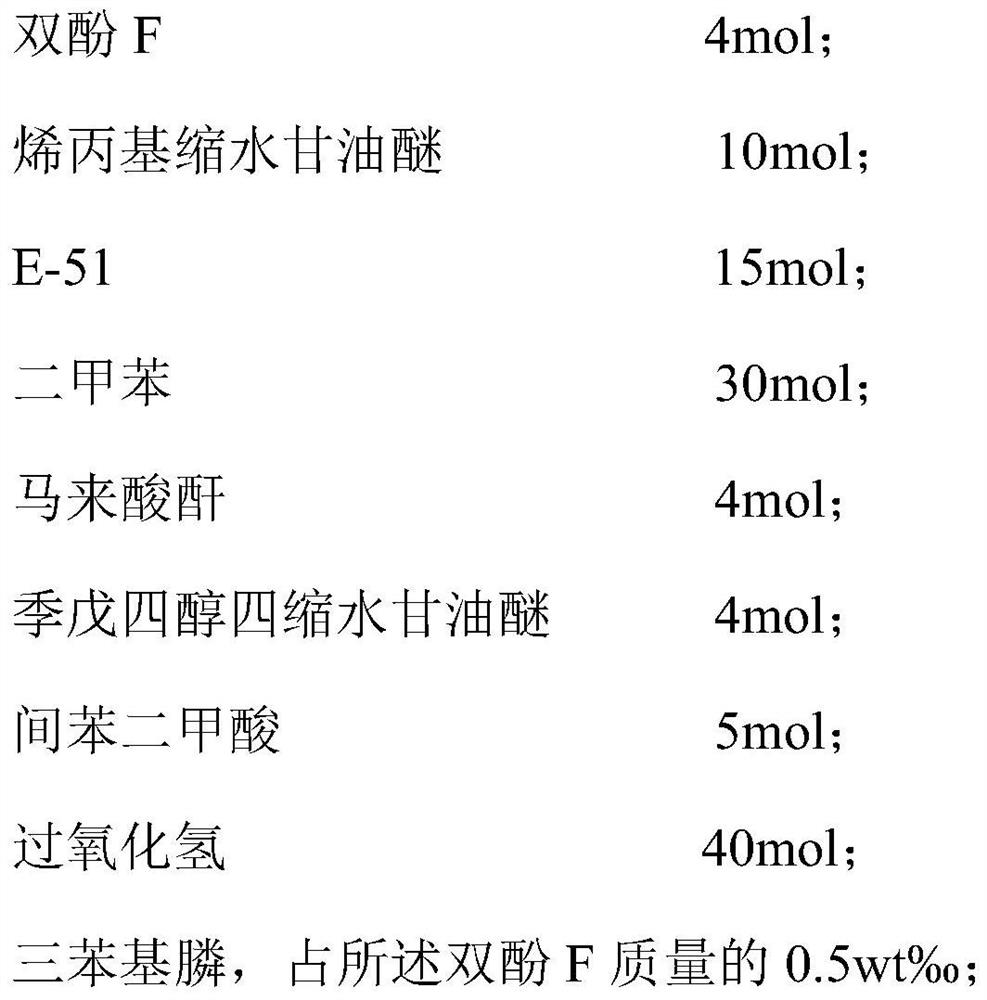

[0051] The high-gloss self-curing epoxy resin described in this embodiment, its preparation raw material comprises the component of following molar weight:

[0052]

[0053] Sodium tungstate: benzyltrimethylammonium chloride = 1:0.3, accounting for 0.4wt% of the mass of bisphenol F.

[0054] The preparation method of high-gloss self-curing epoxy resin described in the present embodiment may further comprise the steps:

[0055] (1) Take the bisphenol F, allyl glycidyl ether, E-51, xylene and ring-opening polymerization catalyst in the formula amount and add them into the reaction kettle, start stirring, gradually heat up to 92°C, and then carry out the heat preservation reaction;

[0056] (2) With the amount of free bisphenol F in the liquid chromatography detection system, when the amount of free bisphenol F in the system is lower than 1%, add the described maleic anhydride and pentaerythritol of formula amount in the reactor at this moment Tetraglycidyl ether, heated up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com