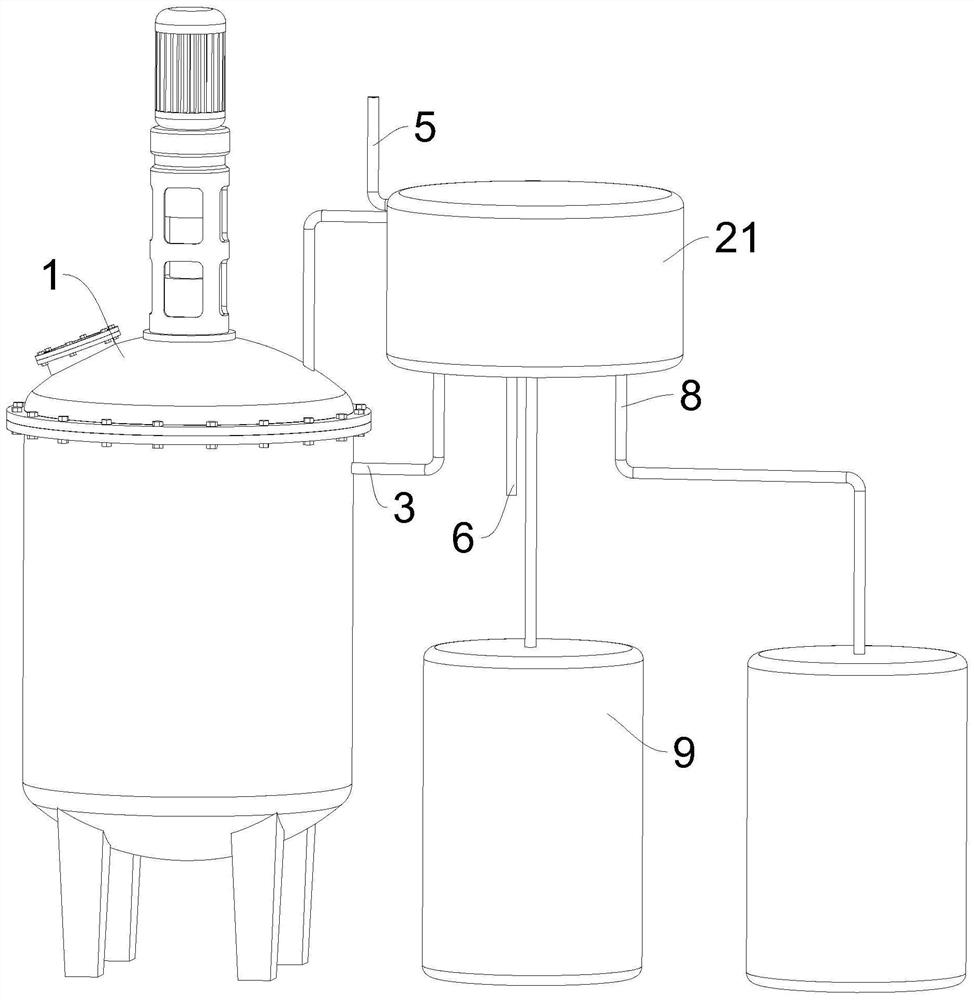

A kind of preparation method of optical resin monomer and its reaction system

An optical resin and monomer technology, applied in the field of preparation of optical resin monomers, can solve the problems of poor punching resistance of optical resin monomers, difficult molding, etc. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

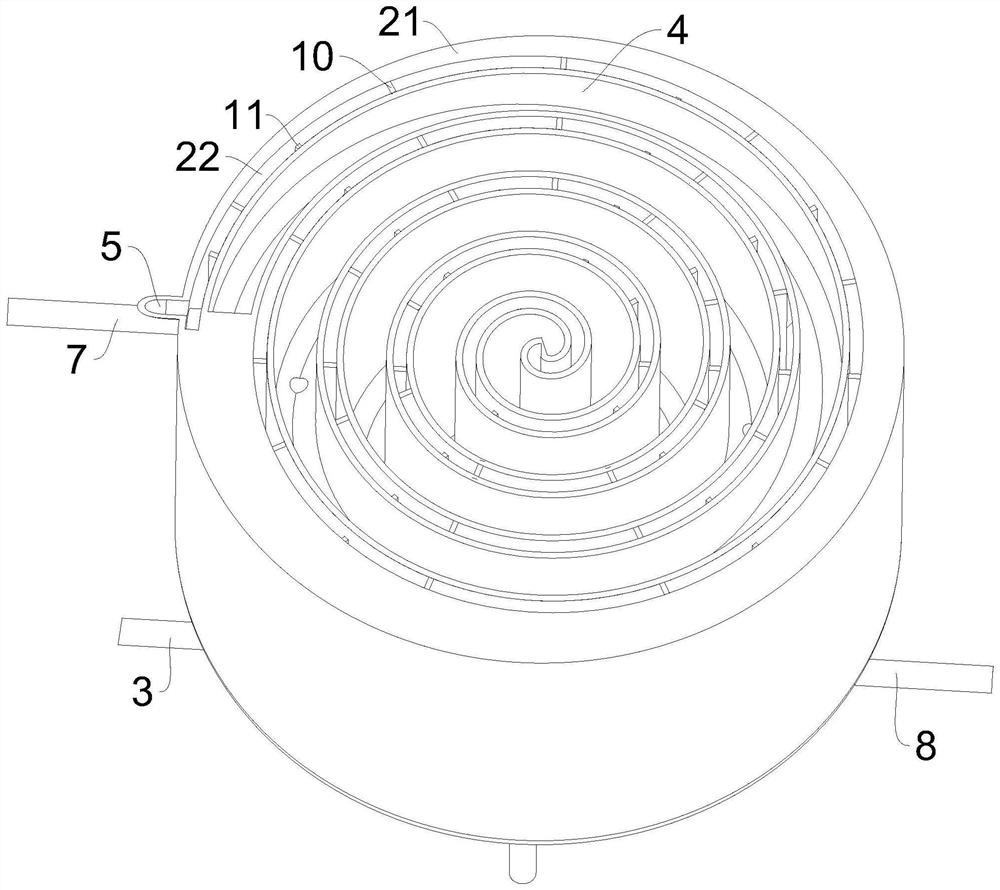

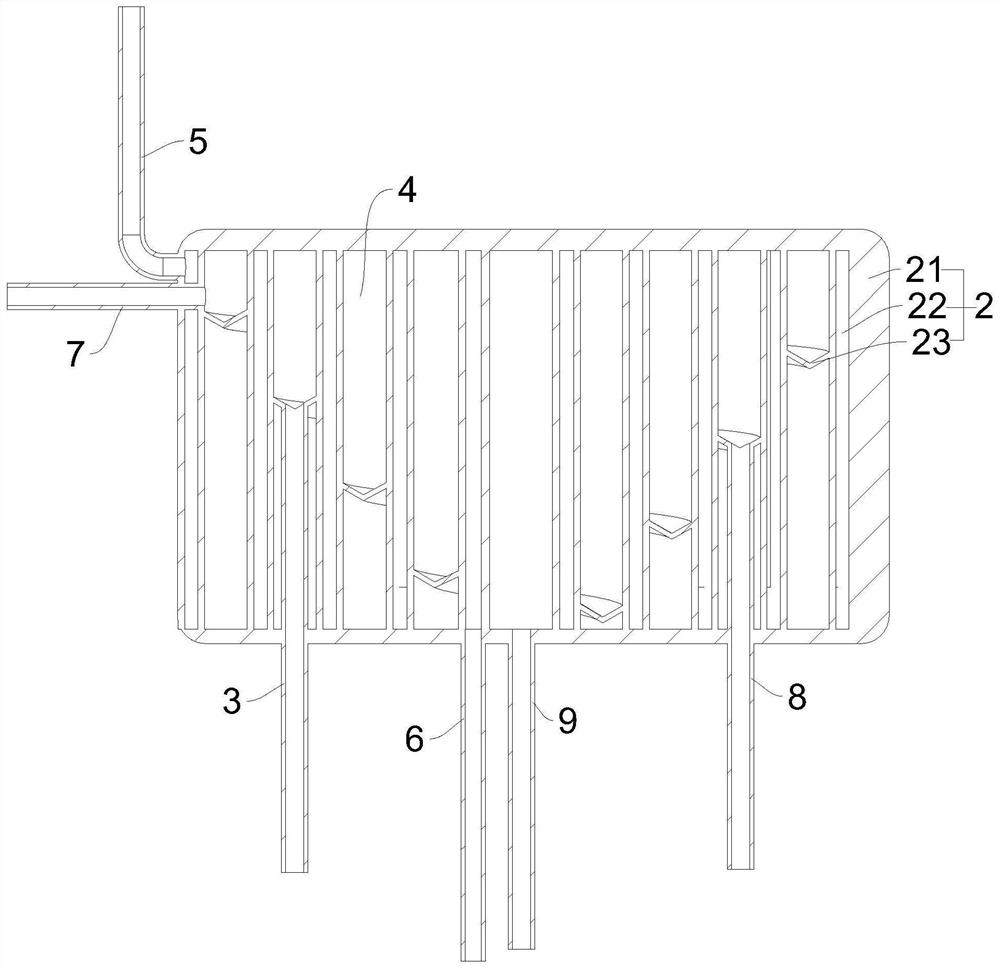

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of an optical resin monomer is carried out according to the following steps:

[0040] S1: in parts by mass, 150 parts of dimethyl terephthalate, 320 parts of allyl alcohol, and 2 parts of calcium hydroxide were added to the glass reactor in turn, and nitrogen protection was introduced, and then the temperature was directly heated to 120° C., The reaction is carried out for 12-15h to obtain a reaction solution. After testing, the yield of the product is 78%. At the same time, a condensation reflux device is set on the glass reaction kettle to condense and reflux allyl alcohol, and the product methanol is recovered;

[0041] S2: transfer the reaction solution obtained in S1 into a vacuum distillation still, heat up to 140° C. for vacuum distillation for 6-10 hours, and the generated vapors are collected by the condensation device for the front fraction and the back fraction respectively;

[0042] S3: add 15 parts of propylene glycol and 2 parts of cal...

Embodiment 2

[0046] A preparation method of an optical resin monomer is carried out according to the following steps:

[0047] S1: in parts by mass, 140 parts of dimethyl terephthalate, 280 parts of allyl alcohol, and 1 part of calcium hydroxide were added to the glass reactor successively, and nitrogen protection was introduced, and then the temperature-programmed mode was adopted, The reaction is carried out for 12-15h to obtain a reaction solution. At the same time, a condensing and refluxing device is set on the glass reaction kettle to condense and reflux allyl alcohol, and the product methanol is recovered;

[0048] S2: transfer the reaction solution obtained in S1 into a vacuum distillation still, heat up to 140° C. for vacuum distillation for 6-10 hours, and the generated vapors are collected by the condensation device for the front fraction and the back fraction respectively;

[0049] S3: add 10 parts of the back fraction, 10 parts of propylene glycol and 1 part of calcium hydroxi...

Embodiment 3

[0054] A preparation method of an optical resin monomer is carried out according to the following steps:

[0055] S1: in parts by mass, 140 parts of dimethyl terephthalate, 280 parts of allyl alcohol, and 1 part of calcium hydroxide were added to the glass reactor successively, and nitrogen protection was introduced, and then the temperature-programmed mode was adopted, The reaction is carried out for 12-15h to obtain a reaction solution. At the same time, a condensing and refluxing device is set on the glass reaction kettle to condense and reflux allyl alcohol, and the product methanol is recovered;

[0056] S2: transfer the reaction solution obtained in S1 into a vacuum distillation still, heat up to 140° C. for vacuum distillation for 6-10 hours, and the generated vapors are collected by the condensation device for the front fraction and the back fraction respectively;

[0057] S3: add 1 part of the back fraction, 1 part of propylene glycol and 1-2 parts of calcium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com