High-aluminum-component nitride ohmic contact device and preparation method thereof

A technology of ohmic contact and nitride, which is applied in the field of microelectronics, can solve the problems of deteriorating device dynamic characteristics, poor quality, and difficult process, so as to avoid dissociation and the introduction of surface defects, reduce contact resistivity, and improve tunneling. The effect of passing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

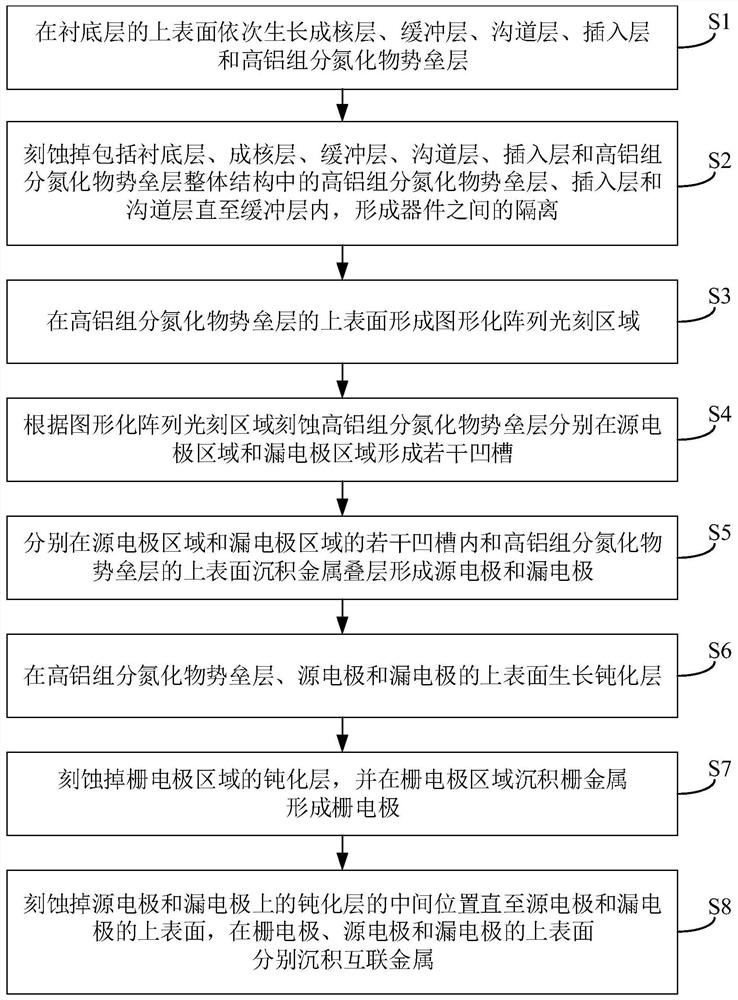

[0051] In order to still prepare an ohmic contact device with low contact resistivity on the basis of simplifying the process, in the first aspect, please refer to figure 1 , an embodiment of the present invention provides a method for preparing a high-aluminum composition nitride ohmic contact device, comprising the following steps:

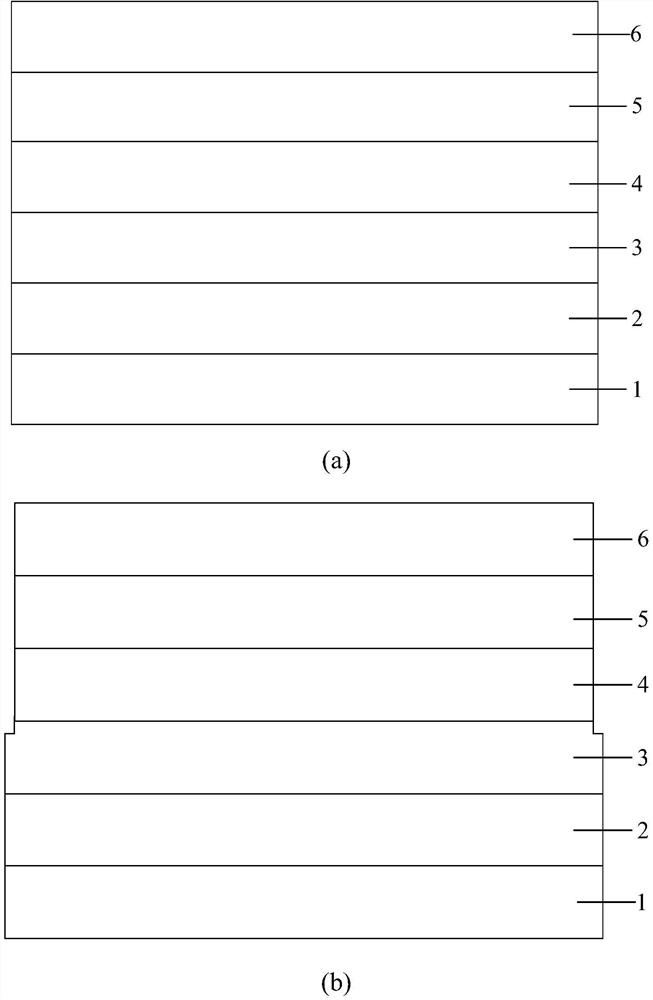

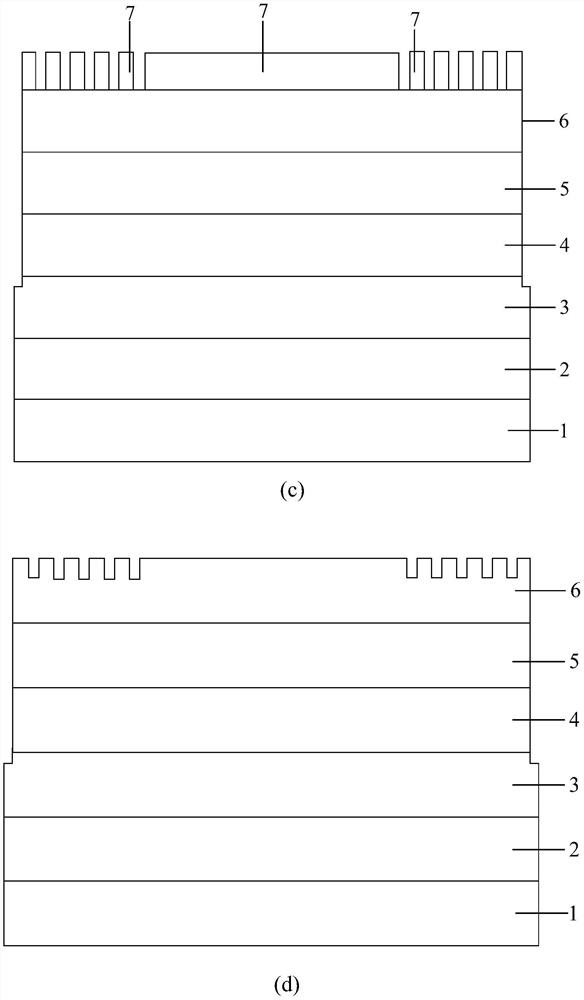

[0052] S1 , growing a nucleation layer 2 , a buffer layer 3 , a channel layer 4 , an insertion layer 5 and a nitride barrier layer 6 with a high aluminum composition in sequence on the upper surface of the substrate layer 1 .

[0053] Specifically, see figure 2 a, Step S1 of the embodiment of the present invention includes: growing an AlN nucleation layer 2 with a thickness of 50 nm to 80 nm on the upper surface of the sapphire or high-resistance Si substrate layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com