Hysteresis heat generation accelerated vulcanization sealant

A technology for accelerated vulcanization and sealant, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc. Precise temperature control, improve heating efficiency, and improve the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

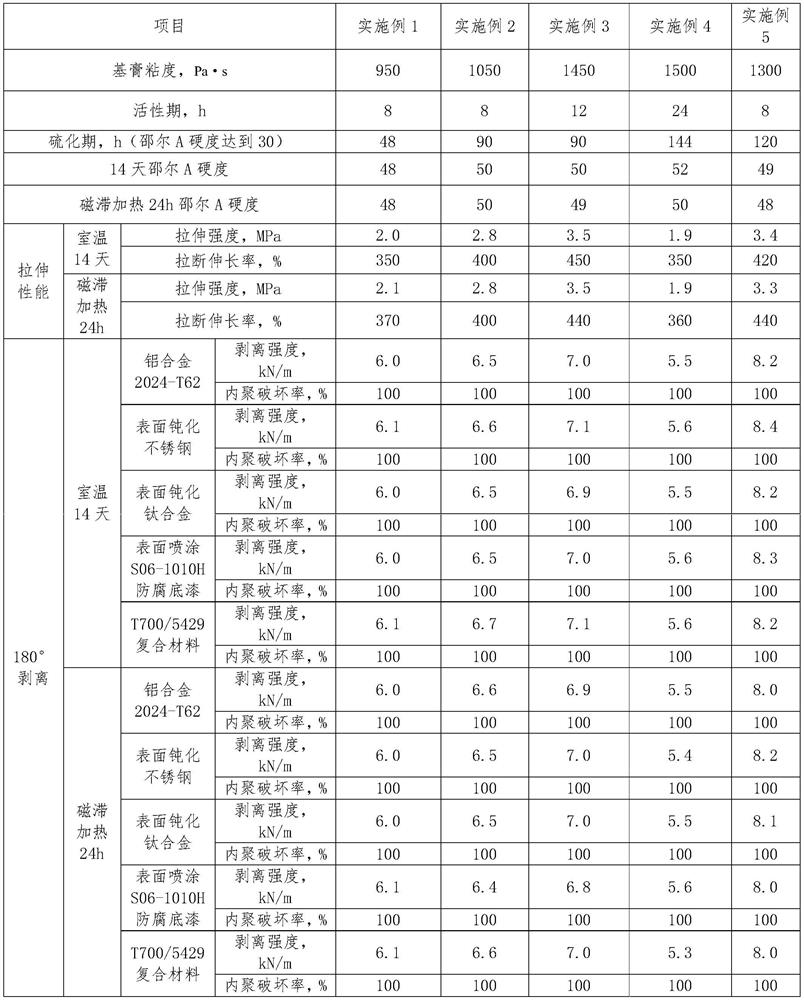

Examples

preparation example Construction

[0027]Preparation of the base paste: Weigh 100 parts of mercapto-terminated liquid rubber, 0-20 parts of filler, and 10-100 parts of magnetic nanomaterials according to the ratio of parts by mass, put them into a mixer and stir them in a vacuum and mix them at a speed of 500-800 Stir for 30-60 minutes at rpm, then add plasticizer, vulcanization accelerator and adhesion promoter according to the ratio of parts by mass, wherein the adhesion promoter is epoxy silane coupling agent and amino titanate coupling agent Equivalent molar ratio of reactants at 40-60°C for 2-4 hours. Then vacuumize and stir at 500-800 rpm for 30-60 minutes to obtain the base paste component.

[0028] Preparation of vulcanizing agent: Weigh 100 parts of manganese dioxide or epoxy resin, 0 to 100 parts of plasticizer, 0 to 10 parts of vulcanization inhibitor, and 0 to 20 parts of filler, and grind on a three-roll mill 4-6 times or vacuumize and stir in a mixer at a speed of 500-800 rpm for 30-60 minutes to...

Embodiment 1

[0031] The hysteresis heat generation accelerated vulcanization sealant in this embodiment is formulated in the following parts by mass.

[0032] Base paste: 100 parts of thiol-terminated polythioether rubber (average molecular weight 10,000, mercapto group content 0.5%), 100 parts of nano-NdFeB magnetic powder treated with KH590 silane coupling agent, Curie temperature 80°C, DMP30 accelerator 5 2 parts, 2 parts of adhesion promoter, among which the adhesion promoter is 3-glycidyl ether oxypropylmethyl trimethoxysilane (brand name KH560) and new alkoxy tris (ethylenediamine N ethoxy) titanium Ester (trade name TCA-L97) reacted at 40°C for 4 hours in equimolar ratio;

[0033] Vulcanizing agent: 50 parts of E44 epoxy resin, 50 parts of F44 epoxy resin, 50 parts of dibutyl phthalate, 20 parts of nano calcium carbonate.

[0034] Preparation method of base paste:

[0035] Weigh 100 parts of mercapto-terminated polythioether with an average molecular weight of 10,000 and a mercapt...

Embodiment 2

[0040] The hysteresis heat generation accelerated vulcanization sealant in this embodiment is formulated in the following parts by mass.

[0041] Base paste: 20 parts of mercapto-terminated butyl rubber (average molecular weight 1000, mercapto content 7%), 80 parts of liquid polysulfide rubber (average molecular weight 5000, mercapto content 1.5%), 5 parts of fumed silica (filler white carbon black , can improve mechanical properties), 10 parts each of nano-NdFeB magnetic powder, ferric oxide nanowires, iron-cobalt alloy nanoparticles treated with Si69 silane coupling agent, 1 part of diphenylguanidine, 4 parts of adhesion promoter, Among them, the adhesion promoter is 3-glycidyl ether oxypropylmethyl dimethoxysilane (the brand is KBM402) and neoalkoxy tris (p-aminophenoxy) titanate (the brand is TCA-L44), etc. The molar ratio is the product reacted at 60°C for 2h;

[0042] Vulcanizing agent: 100 parts of manganese dioxide, 100 parts of dibutyl phthalate, 2 parts of stearic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com