Preparation of three-dimensional conductive framework and application of three-dimensional conductive framework in ferric oxide photo-anode

A skeleton, three-dimensional technology, applied in the preparation of three-dimensional conductive skeleton, the application field of iron oxide photoanode, can solve the problems of low economic benefit, unsuitable for industrialization, high equipment requirements, etc., to increase the specific surface area, facilitate industrialization, and prepare methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

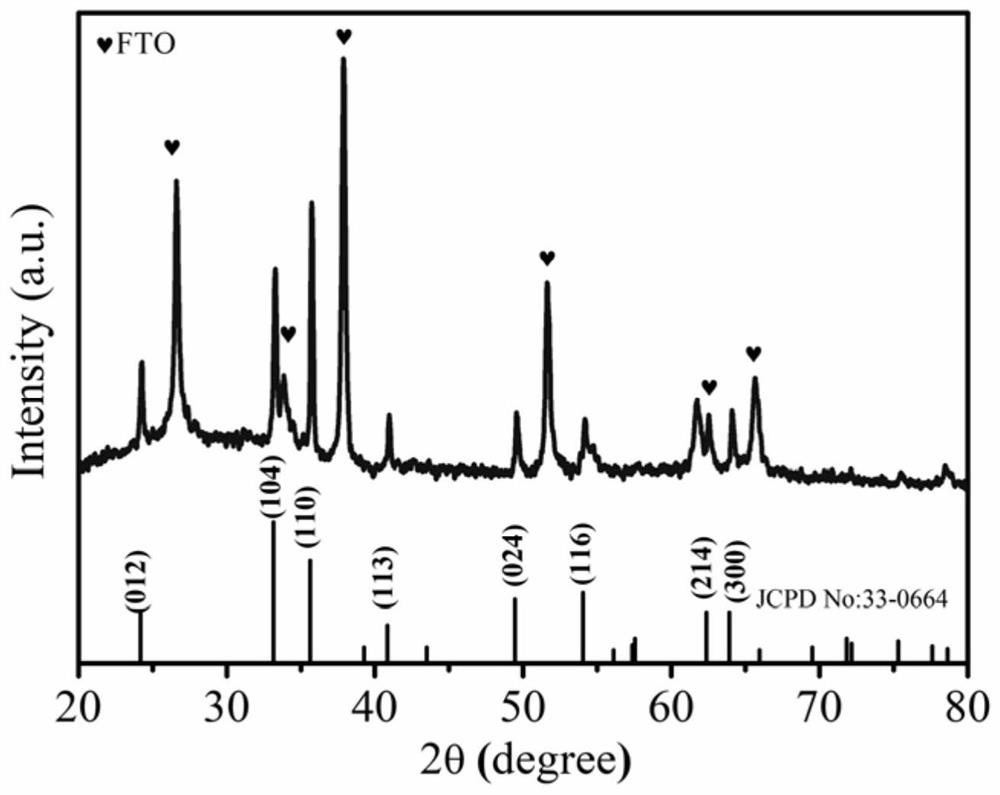

[0046] In this example, after FTO is prepared by the method described in the present invention to obtain a three-dimensional conductive framework, the process of preparing an iron oxide photoanode through in-situ growth and the photoelectric performance test specifically include:

[0047] (1) Add 1.2mL ethanol, 0.8mL n-butanol and 0.025g sodium chloride to 0.5mL polystyrene (PS) microsphere solution with a mass concentration of 5%, the diameter of PS microspheres is 500nm, and then ultrasonically mix for 15min , to form solution A1; 1.2mL ethanol, 0.8mL n-butanol and 0.025g sodium chloride are added to 0.5mL mass concentration of 5% polystyrene (PS) microsphere solution, PS microsphere diameter is 300nm, then ultrasonic Mix for 15 minutes to form solution A2; add 40 mL of deionized water to a watch glass with a diameter of 10 cm, then add dropwise 6 uL of 3% sodium lauryl sulfate solution and stir evenly to form solution B.

[0048] (2) Draw 0.1mL of solution A1 and drop it on...

Embodiment 2

[0055] In this example, after FTO is prepared by the method described in the present invention to obtain a three-dimensional conductive framework, the process of preparing an iron oxide photoanode through in-situ growth and the photoelectric performance test specifically include:

[0056] (1) Add 1.2mL of ethanol, 0.8mL of n-butanol and 0.025g of sodium chloride into 0.5mL of polystyrene (PS) microsphere solution with a mass concentration of 5%. The diameter of PS microspheres is 300nm, and then ultrasonically mix for 15min , to form solution A1; 1.2mL ethanol, 0.8mL n-butanol and 0.025g sodium chloride are added to 0.5mL mass concentration of 5% polystyrene (PS) microsphere solution, PS microsphere diameter is 500nm, then ultrasonic Mix for 15 minutes to form solution A2; add 40 mL of deionized water to a watch glass with a diameter of 10 cm, then add dropwise 6 uL of 3% sodium lauryl sulfate solution and stir evenly to form solution B.

[0057] (2) Draw 0.1mL of solution A1 ...

Embodiment 3

[0064] In this example, after FTO is prepared by the method described in the present invention to obtain a three-dimensional conductive framework, the process of preparing an iron oxide photoanode through in-situ growth and the photoelectric performance test specifically include:

[0065] (1) Add 1.2mL of ethanol, 0.8mL of n-butanol and 0.025g of sodium chloride into 0.5mL of polystyrene (PS) microsphere solution with a mass concentration of 5%. The diameter of PS microspheres is 300nm, and then ultrasonically mix for 15min , to form solution A1; 1.2mL ethanol, 0.8mL n-butanol and 0.025g sodium chloride are added to 0.5mL mass concentration of 5% polystyrene (PS) microsphere solution, PS microsphere diameter is 200nm, then ultrasonic Mix for 15 minutes to form solution A2; add 40 mL of deionized water to a watch glass with a diameter of 10 cm, then add dropwise 6 uL of 3% sodium lauryl sulfate solution and stir evenly to form solution B.

[0066] (2) Draw 0.1mL of solution A1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com