Preparation method of KTN/PI composite film with high breakdown voltage and low dielectric loss

A composite film and high breakdown technology, which is applied in the field of preparation of KTN/PI composite film, can solve the problems of increased energy consumption and high temperature, and achieve the effects of increased breakdown field strength, reduced energy consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

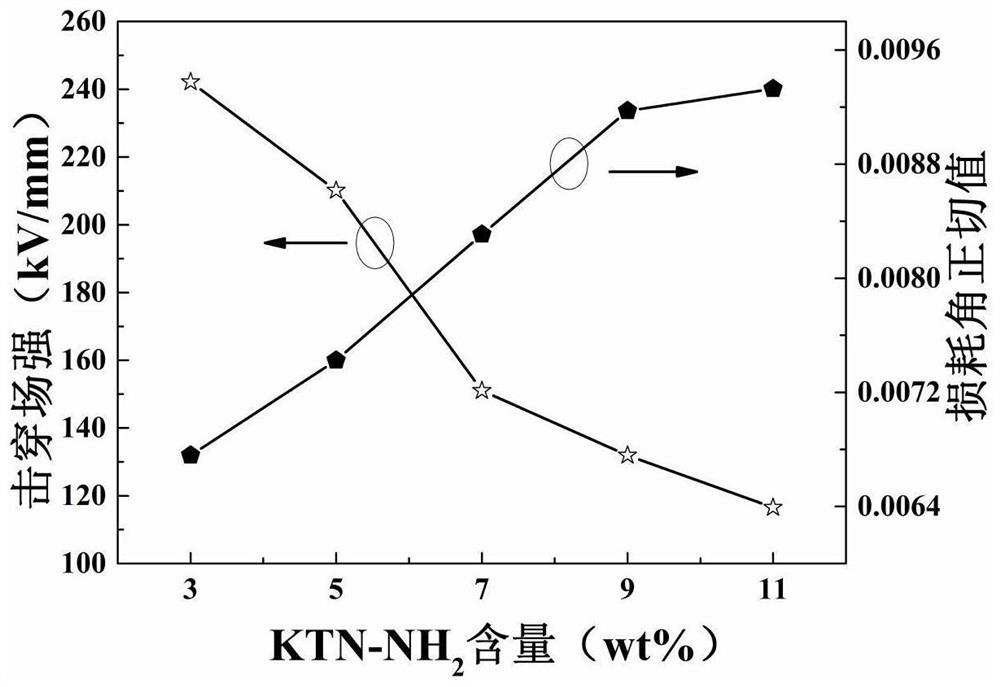

[0028] Example 1: KTN-NH 2 / PI composite film 1

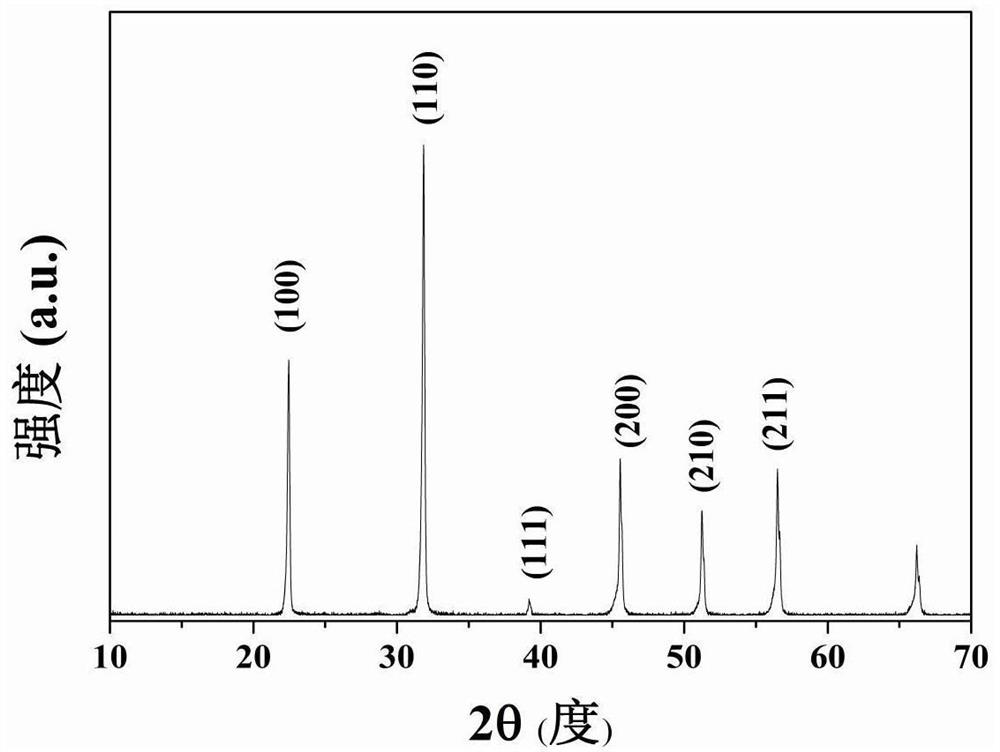

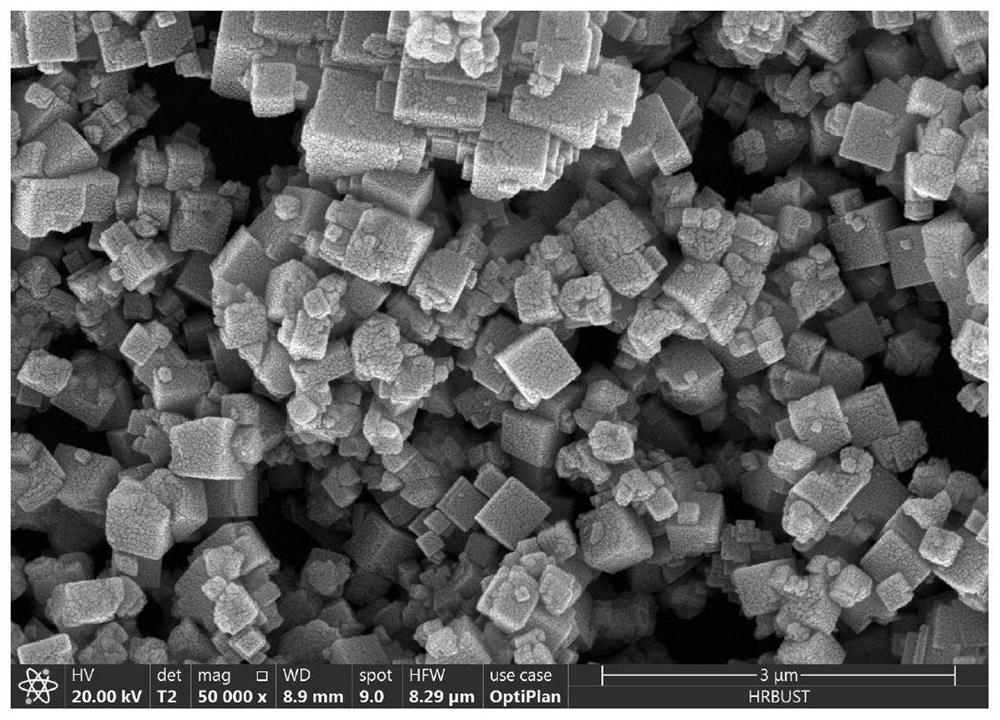

[0029] 1) Hydrothermal method synthesizing potassium nanostructure (KTN) to obtain KTN powder;

[0030] 2) The KTN is modified based on the simple solution method, and N, N'-dimethylformamide (DMF) is selected as a solvent, and 1 gram of KTN powder is dissolved in a 10 ml DMF solution to obtain a mixture 1;

[0031] 3) Stirring at normal temperature, slowly dropped into the mixture 1 of 3- (2-aminoethylene) propyl methoxycidilisily dipolygene as a modifier, pair The KTN surface was modified, followed by 24 hours, the resulting product was washed twice with DMF and ethanol, respectively, 10 hours at 60 degrees Celsius, resulting in an amino-free KTN-NH. 2 powder;

[0032] 4) A polyimide group (PI) composite film precursor is prepared by an in-situ polymerization method, which will be modified KTN powder (KTN-NH 2 Add to the precursor, heat 1 hour at the temperature of 80, 100, 200, 300, and 330 degrees Celsius, and the KTN-NH is ad...

Embodiment 2

[0036] Example 2: KTN-NH 2 / PI composite film 2

[0037] 1) Hydrothermal method synthesizing the KTN powder of the nanostructure;

[0038] 2) The KTN is modified based on the simple solution method, and N, N'-dimethylformamide (DMF) is selected as a solvent, and 1 gram of KTN powder is dissolved in a 10 ml DMF solution to obtain a mixture 1;

[0039] 3) Stirring at normal temperature, slowly dropped into the mixture 1 of 3- (2-aminoethylene) propyl methoxy silicone coupling agent of 13: 1 as a modifier, pair The KTN surface was modified, followed by reaction for 22 hours, the resulting product was washed twice with DMF and ethanol, respectively, 10 hours at 60 degrees Celsius, resulting in an amino-based KTN-NH. 2 powder;

[0040] 4) A polyimide group (PI) composite film precursor is prepared by an in-situ polymerization method, which will be modified KTN powder (KTN-NH 2 In the top of the precursor, it is 1 hour at 80, 100, 200, 300, and 330 degrees Celsius, and KTN-NH having a ...

Embodiment 3

[0042] Example 3: KTN-NH 2 / Pi composite film 3

[0043] 1) Hydrothermal method synthesizing the KTN powder of the nanostructure;

[0044] 2) REprising treatment, N, N'-dimethylformamide (DMF) is used as a solvent based on a simple solution method, and 1 gram of KTN powder is dissolved in a 10 ml DMF solution to obtain a mixture 1;

[0045] 3) Stirring at normal temperature, slowly dropped into the mixture 1 of 3- (2-aminoethylene) propyl methoxycidilisilyl coupling agent having a KTN mass ratio of 10: 1 as a modifier. The KTN surface was modified, followed by reaction for 20 hours, and the resulting product was washed twice with DMF and ethanol, respectively, dried at 60 degrees Celsius for 10 hours, and obtained an amino-free KTN-NH. 2 powder;

[0046] 4) A polyimide group (PI) composite film precursor is prepared by an in-situ polymerization method, which will be modified KTN powder (KTN-NH 2 In the top of the precursor, it is 1 hour at 80, 100, 200, 300, and 330 degrees Celsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com