High-oxygen-permeability corneal contact lens and preparation method thereof

A corneal contact lens and oxygen transmission rate technology, which are applied in the preparation of polysiloxane macromonomer cross-linking agent materials, the preparation of high oxygen transmission rate corneal contact lenses, and the surface hydrophilic modification of corneal contact lenses. , can solve the problems of low oxygen permeability, low water content of lenses, development and application limitations, etc., to achieve the effect of comfortable wearing and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

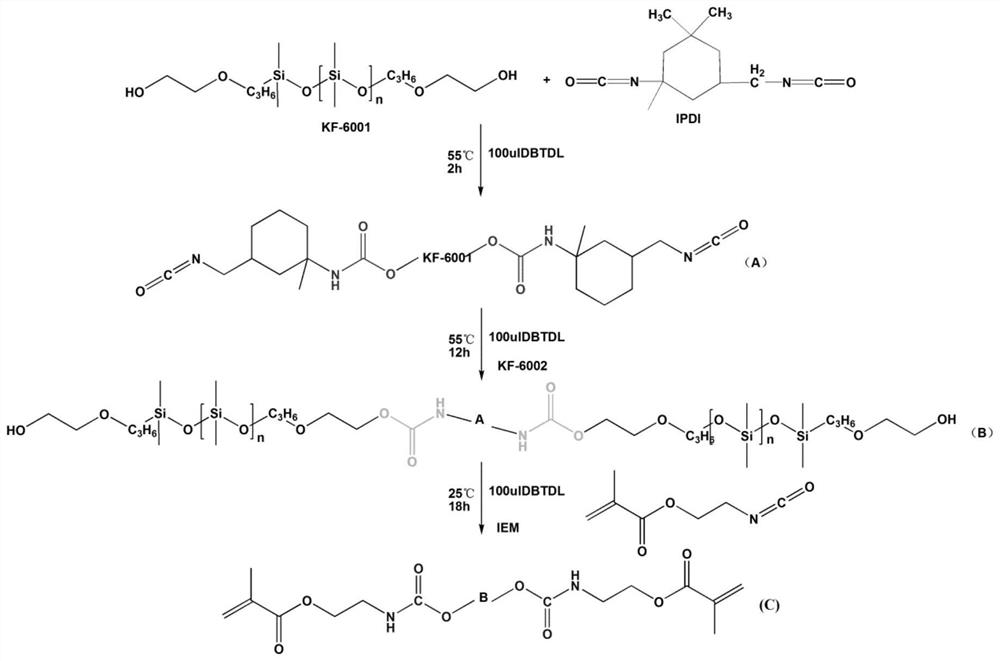

[0037] The present embodiment discloses a kind of preparation of the polydimethylsiloxane macromonomer cross-linking agent of hydrophilic segment modification, double bond termination, and it comprises the following steps:

[0038] 1. Add KF-6001 (7.5g) into a 100ml branch bottle, insert it into a mechanical stirrer, coat the cock with vacuum ester, connect the branch with a vacuum line, put it in a water bath at 55°C, and dry it in vacuum for 2 hours.

[0039] 2. At the same time, weigh KF-6002 (30g) and add it to a single-necked flask, and the drying method is the same as above.

[0040]Under mechanical stirring at 3300rpm, add IPDI (1.67g), stir at 55°C until completely dissolved, use a 100ul microsampler to absorb DBTDL (100ul) and drop it into the reactor (>10min), and react for 2h.

[0041] 4. Use a syringe to draw KF-6002 (24.8g) into the reactor, use a 100ul micro-sampler to draw DBTDL (100ul) dropwise into the reactor, and react overnight at 55°C.

[0042] 5. Equilib...

Embodiment 2

[0045] This embodiment discloses a kind of preparation method of silicon hydrogel material on the basis of embodiment 1, and it comprises the following steps:

[0046] Measure the polydimethylsiloxane macromonomer crosslinking agent in the embodiment 1 of 41.7% by mass percentage, the N'N-dimethylacrylamide (DMA) of 22.6% by mass percentage, the formazan of 15.9% by mass percentage Acryloyloxypropyl tris(trimethylsiloxane)silane (Tris), 1.0% by mass of Darocur 1173, dissolved in 18.8% by mass of n-propanol diluent, magnetically stirred for 20 minutes, and ultrasonically eliminated Soak for 10 minutes to obtain a polymerization solution for later use. Use a pipette gun to draw 5ml of the polymerization solution and drop it into a polytetrafluoroethylene mold with a 5*5*0.2cm inner groove. After the drop is full, cover the mold with a 6*6*0.2cm glass plate, and place the whole under ultraviolet light. Under light, polymerize for 40min. Lift the glass plate, take off the polyme...

Embodiment 3

[0048] The present embodiment discloses a kind of preparation method of silicon hydrogel contact lens on the basis of embodiment 2, and it comprises the following steps:

[0049] Measure the polydimethylsiloxane macromonomer crosslinking agent in the embodiment 1 of 41.7% by mass percentage, the N'N-dimethylacrylamide (DMA) of 22.6% by mass percentage, the formazan of 15.9% by mass percentage Acryloyloxypropyl tris(trimethylsiloxane)silane (Tris), 1.0% by mass of Darocur 1173, dissolved in 18.8% by mass of n-propanol diluent, magnetically stirred for 20 minutes, and ultrasonically eliminated Soak for 10 minutes to obtain a polymerization solution for later use. Use a pipette to draw 20 μL of the polymerization solution and drop it into the female mold of the polypropylene contact lens mold. After the drip is full, cover the male mold on the mold, place the whole under ultraviolet light, and polymerize for 30 minutes. After the reaction, open the mold, the lens will be attache...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap