Multi-element Zn-Sn-Cu-Bi-Nd brazing filler metal for brazing of sintered Nd-Fe-B and steel and preparation process of multi-element Zn-Sn-Cu-Bi-Nd brazing filler metal

A zinc-tin-copper-bismuth, neodymium-iron-boron technology used in manufacturing tools, welding equipment, welding/cutting media/materials, etc. problem, to achieve the effect of high mechanical properties, good wetting properties, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

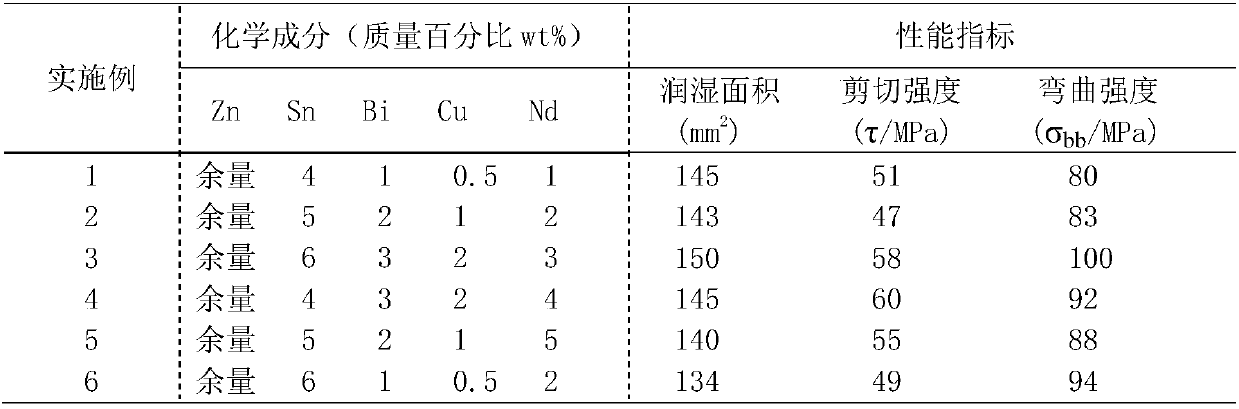

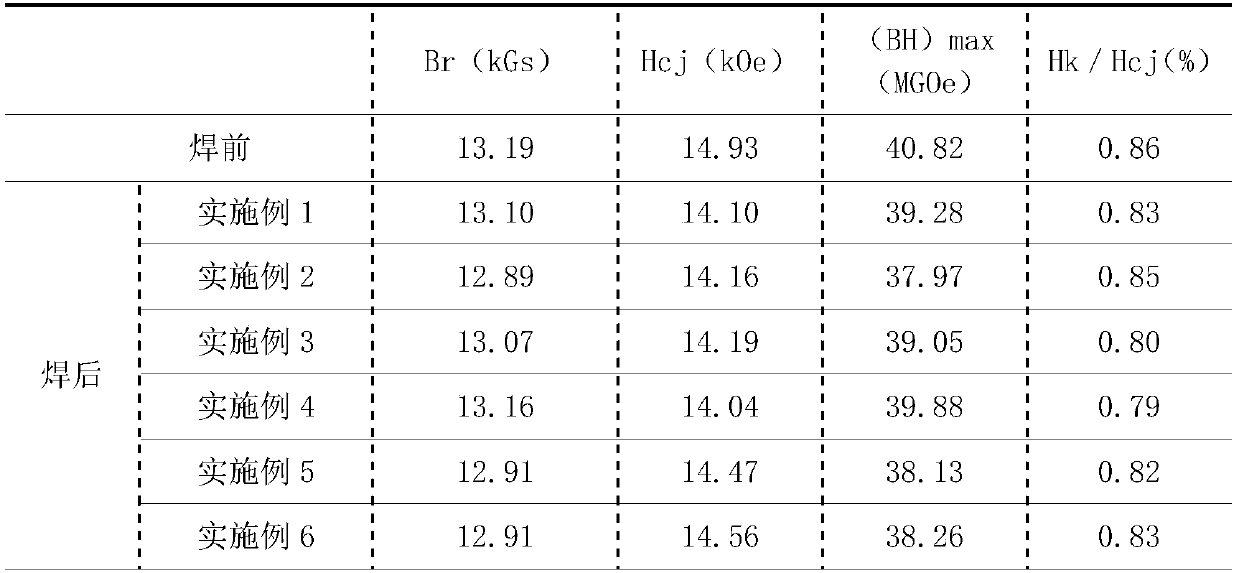

[0016] The method of the present invention will be further specifically described through the following examples in conjunction with the accompanying drawings.

[0017] A multi-element zinc-tin-copper-bismuth-neodymium solder for brazing and sintering NdFeB and steel, using zinc as the basic alloy component of the solder, adding tin, copper, bismuth and neodymium elements to form a multi-element zinc-tin-copper-bismuth-neodymium solder, brazing Material alloy composition by mass percentage (Wt / %): tin (Sn): 4-6, copper (Cu): 0.5-2, bismuth (Bi): 1-3, neodymium (Nd): 1-5, more than amount of zinc (Zn).

[0018] The sintered NdFeB magnetic material is hard and brittle, with poor plasticity and toughness, the surface is easily oxidized and corroded, the Curie temperature is low (T=320°C-460°C), and the weldability is extremely poor. Therefore, the solder used for brazing and sintering NdFeB magnetic materials requires a moderate melting temperature, which matches the Curie tempe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap