Recombinant corynebacterium glutamicum and application thereof in production of L-glutamine

A technology of Corynebacterium glutamicum and glutamine, applied in the field of bioengineering, can solve the problems of low yield and low yield of L-glutamine production strains, achieve enhanced ATP content, increase yield, and solve imbalance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the acquisition of Corynebacterium glutamicum (Corynebacterium glutamicum) N01 bacterial strain

[0061] Specific steps are as follows:

[0062] (1) Preparation of bacterial suspension: Pick Corynebacterium glutamicum ATCC 14067 from a glycerol tube at -80°C with an inoculation loop, draw lines in three sections on BHI solid medium, and culture in a 30°C incubator for 24 hours; Take the activated single colony from the plate, inoculate it into a 50 mL shake flask containing 10 mL of BHI liquid medium, and cultivate it to OD at 30°C and 220 rpm 600 About 10 (logarithmic growth phase); centrifuge at 8000rpm for 3min to collect cells, and wash twice with 50mL 0.1M phosphate buffer saline (PBS); finally add a certain amount of PBS solution to make the bacterial concentration about 10 8 CFU / mL, the bacterial suspension was prepared;

[0063] (2) Atmospheric room temperature plasma (ARTP) mutagenesis: use ARTP-IIIS instrument, use high-purity helium as the wor...

Embodiment 2

[0067] Embodiment 2: Construction of Corynebacterium glutamicum (Corynebacterium glutamicum) CGQ01

[0068] Specific steps are as follows:

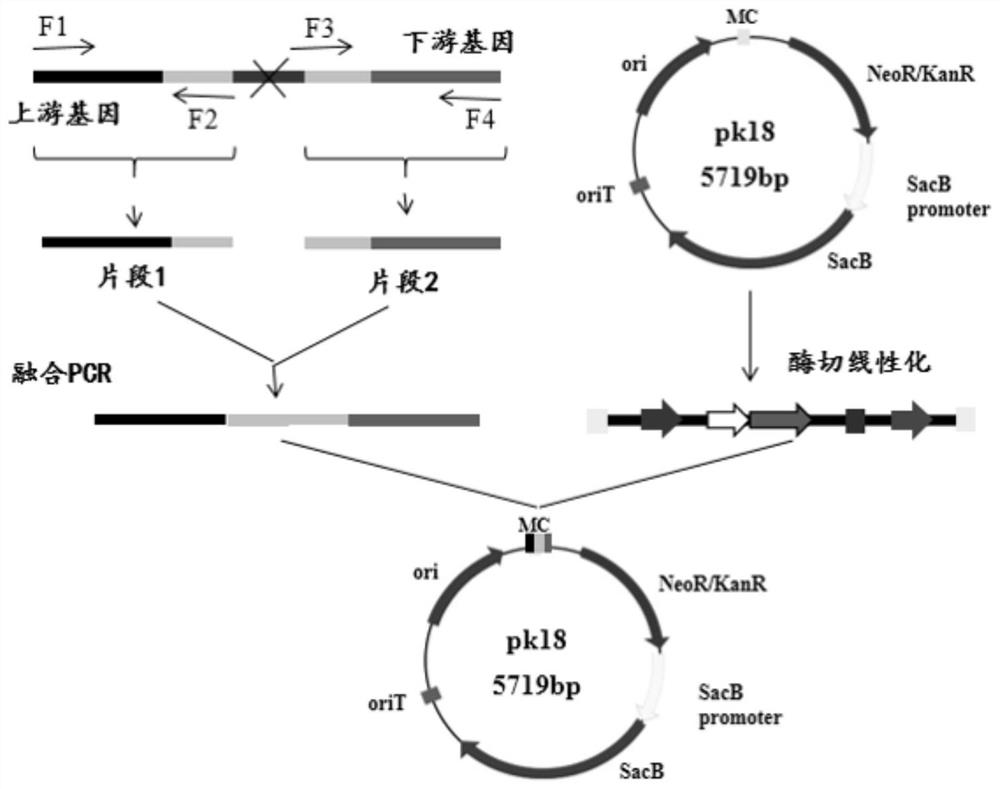

[0069] (1) Construction of knockout plasmid pK18mobsacB-ΔproB

[0070] From the gene proB sequence (NCBI Genebank accession number BA000036.3) of the γ-glutamate kinase gene on the Corynebacterium glutamicum ATCC 13032 genome published on the NCBI website, determine the sequence position of the proB gene and determine that the missing fragment is 271-836, select proB Gene fragments of about 800 bp in size before and after the deletion fragment serve as upstream and downstream homology arms, and the sequences are shown in SEQ ID NO.6 and SEQ ID NO.7.

[0071] Using primers P1 / P2 and P3 / P4 to amplify the upstream and downstream homology arm fragments of the proB gene base deletion site from the genome of Corynebacterium glutamicum N01, the PCR program is: 95°C, 10min; 95°C, 30s; 58°C, 30s; 72°C, 1min; 72°C, 10min, cycle 30 times. After p...

Embodiment 3

[0080] Embodiment 3: Construction of Corynebacterium glutamicum (Corynebacterium glutamicum) CGQ02

[0081] Specific steps are as follows

[0082] (1) Construction of knockout plasmid pK18mobsacB-ΔNCgl1221

[0083] From the gene NCgl1221 sequence (NCBI Genebank accession number: NC_003450.3) of the glutamate mechanochannel protein on the Corynebacterium glutamicum ATCC 13032 genome published on the NCBI website, determine the sequence position of the NCgl1221 gene and determine that the missing fragment is 401-1203, select Gene fragments of about 900 bp in size before and after the NCgl1221 deletion fragment serve as upstream and downstream homology arms, and the sequences are shown in SEQ ID NO.8 and SEQ ID NO.9.

[0084] According to the method of embodiment 2 step (1), using primers P5 / P6 and P7 / P8 to amplify the upstream and downstream homology arm fragments of the NCgl1221 gene base deletion site from the genome of Corynebacterium glutamicum N01, two obtained After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com