Palladium-molybdenum bimetallic catalyst as well as preparation method, preparation equipment and application thereof

A bimetallic catalyst and crystallization technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems that the reaction kettle cannot be carried out, the time is long, and the discovery is not found, so as to strengthen the experimental time and process. Control, reduce impact, reduce the effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

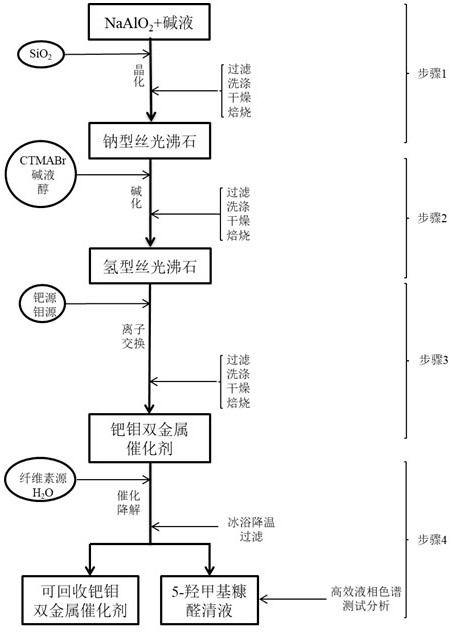

[0053] A preparation method of a palladium-molybdenum bimetallic catalyst, comprising the following steps:

[0054] (1) NaAlO 2 , The first lye and deionized water are mixed according to the molar ratio of 1: (0.5-10): (50-1000), and the SiO 2 with NaAlO 2 The molar ratio is 1: (10-40) by adding SiO 2 Carrying out crystallization, after the crystallization is completed, filtering, washing, drying and roasting to obtain sodium mordenite;

[0055] Among them, the crystallization temperature is 100-300°C, the crystallization time is 10-80h, the drying temperature is 50-150°C, the drying time is 1-10h, the roasting temperature is 400-700°C, and the roasting time is 5-10h;

[0056] (2) The sodium mordenite, template agent, second lye, alcohol solution and deionized water are mixed according to the molar ratio of 1: (0.1-50): (1-100): (1-700): (200-2000) mixed in a ratio of 2000 to 2000 for alkalization treatment, and the product after alkalization treatment was filtered and was...

Embodiment 2

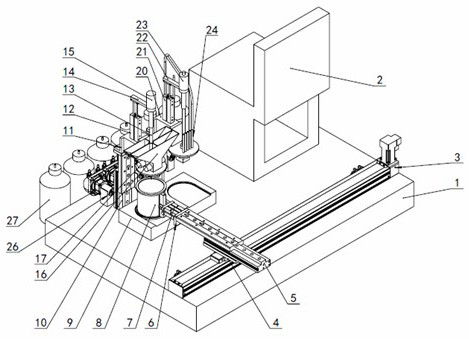

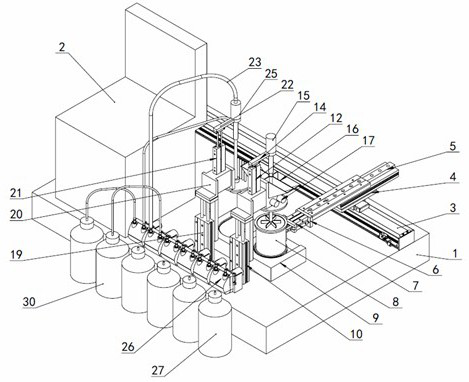

[0066] Such as Figure 2-7 Shown, a kind of equipment for preparing palladium molybdenum bimetallic catalyst comprises:

[0067] Such as figure 2 As shown, the reaction vessel moving module is used to move the reaction vessel 8 to different experimental stations, including the installation main board 1, the left and right movement module 3, the front and rear guiding cylinders 5, and the air claws 7 for clamping the reaction vessel 8. The installation main board 1 is provided with a left and right moving module 3, the front and rear guide cylinder 5 is installed on the sliding part of the left and right moving module 3 through the cylinder mounting plate 4, and the air claw 7 is installed through the air claw mounting plate 6 On the sliding part of the front and rear guide cylinder 5;

[0068] Such as Figure 3-5 As shown, the feeding and mixing module includes a temperature control platform 9, a feeding cylinder 10, a stirring and lifting cylinder 12, an agitator 13, an a...

Embodiment 3

[0077] Such as figure 2 As shown, the reaction vessel 8 can be clamped by the air claws 7, and moves back and forth, left and right under the action of the left and right moving module 3 and the front and rear guiding cylinder 5. The left and right movement module 3 moves to the first position corresponding to the feeding and stirring position of the reaction vessel 8, the left and right movement module 3 moves to the second position corresponding to the filter washing position of the reaction vessel 8, and the left and right movement module 3 to the third position corresponds to the reaction vessel 8. Roasting position.

[0078] A preparation method of a palladium-molybdenum bimetallic catalyst, comprising the following steps:

[0079] Take 29g SiO 2 (Station II), 20 g of cetyltrimethylammonium bromide template agent (CTMABr) (Station III), and 2 g of microcrystalline cellulose powder (Station IV) were loaded into 3 boxes of 16 The stations are respectively recorded as st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com