Polyol ester-water-based microemulsion type drying cylinder stripping agent and preparation method thereof

A polyol ester and drying cylinder peeling technology, applied in the direction of coating, etc., can solve the problems of poor storage stability, poor peeling effect, and oily smell, and achieve strong thermodynamic stability, good peeling effect, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

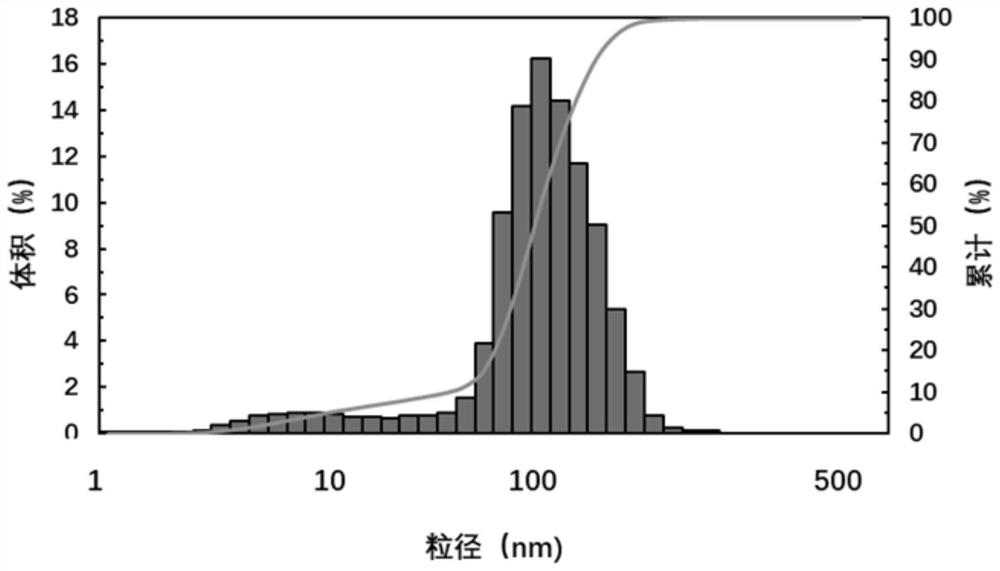

[0028] Add 30g of pentaerythritol oleate, 6g of EL80 (castor oil polyoxyethylene ether 80), and 15g of propylene glycol into the reaction kettle in sequence, and turn on the stirring speed at 100rpm until a uniform solution is formed. Increase the stirring speed to 800 rpm, slowly add 49 g of deionized water, and stir until a uniform white emulsion is formed. Then, the white emulsion was ultrasonically emulsified at 50° C. for 1 hour to form a microemulsion with a particle size of 10-200 nm, and the appearance was a transparent bluish uniform liquid.

Embodiment 2

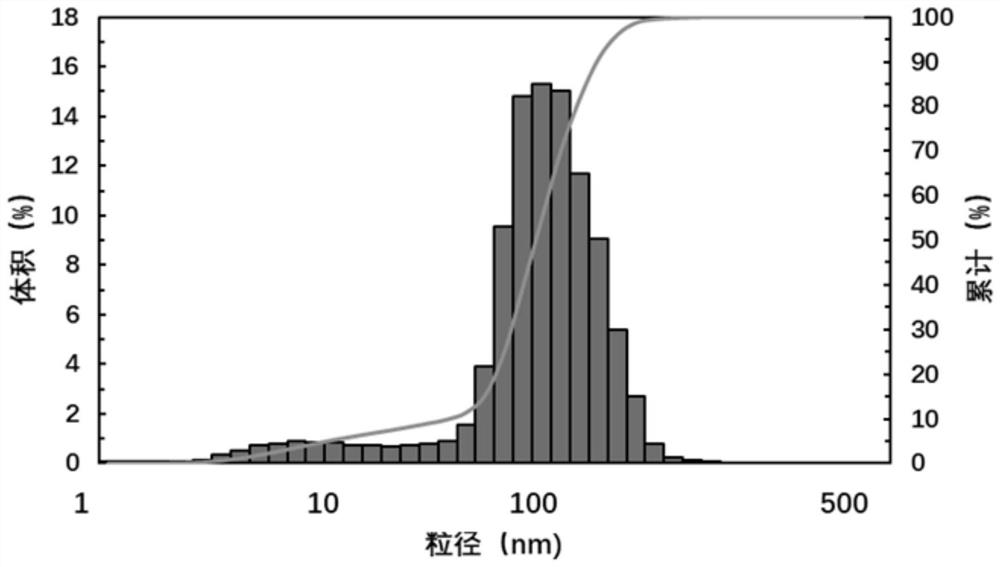

[0030] Add 30g of glycerin trioleate, 6g of AEO-20 (fatty alcohol polyoxyethylene ether), and 15g of glycerin into the reaction kettle in sequence, and turn on the stirring speed at 100rpm until a uniform solution is formed. Increase the stirring speed to 800 rpm, slowly add 49 g of deionized water, and stir until a uniform white emulsion is formed. Then, the white emulsion was ultrasonically emulsified at 50° C. for 1 hour to form a microemulsion with a particle size of 10-200 nm, and the appearance was a transparent bluish uniform liquid.

Embodiment 3

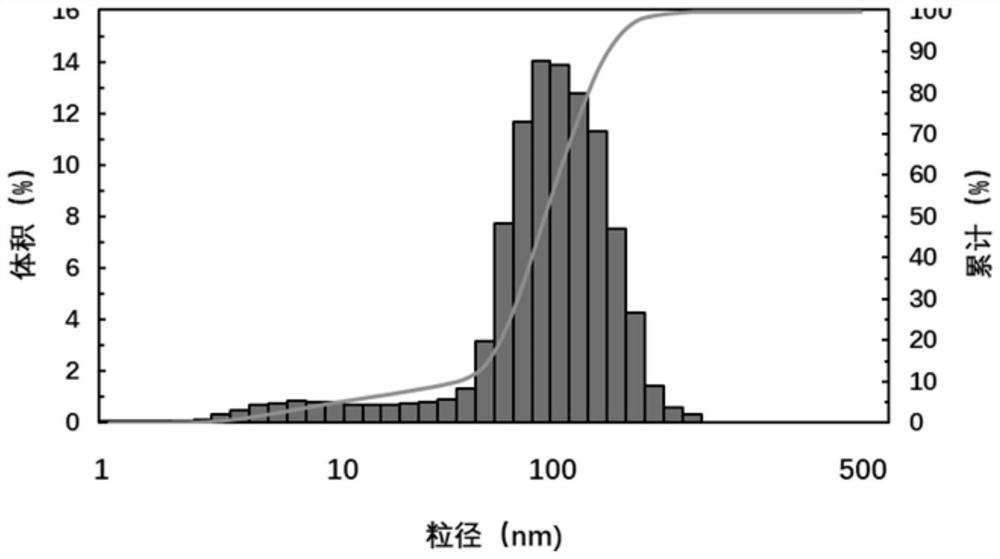

[0032] Add 20g triglyceride oleate, 4g AEO-20 (fatty alcohol polyoxyethylene ether), and 5g dipropylene glycol into the reaction kettle in sequence, and turn on the stirring speed at 100rpm until a uniform solution is formed. Increase the stirring speed to 800 rpm, slowly add 71 g of deionized water, and stir until a uniform white emulsion is formed. Then the white emulsion is ultrasonically emulsified at 50° C. for 1 hour to form a microemulsion with a particle size of 10-200 nm, and the appearance is a transparent bluish homogeneous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com