Preparation method and application of nickel-rich cobalt-free single crystal positive electrode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in the field of nickel-rich cobalt-free single crystal positive electrode materials and their preparation, can solve the problems of poor electrochemical performance, high lithium-nickel mixed discharge, agglomeration and other problems, and achieve improved electrochemical performance. performance, reducing lithium-nickel mixing, and suppressing multiple phase transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

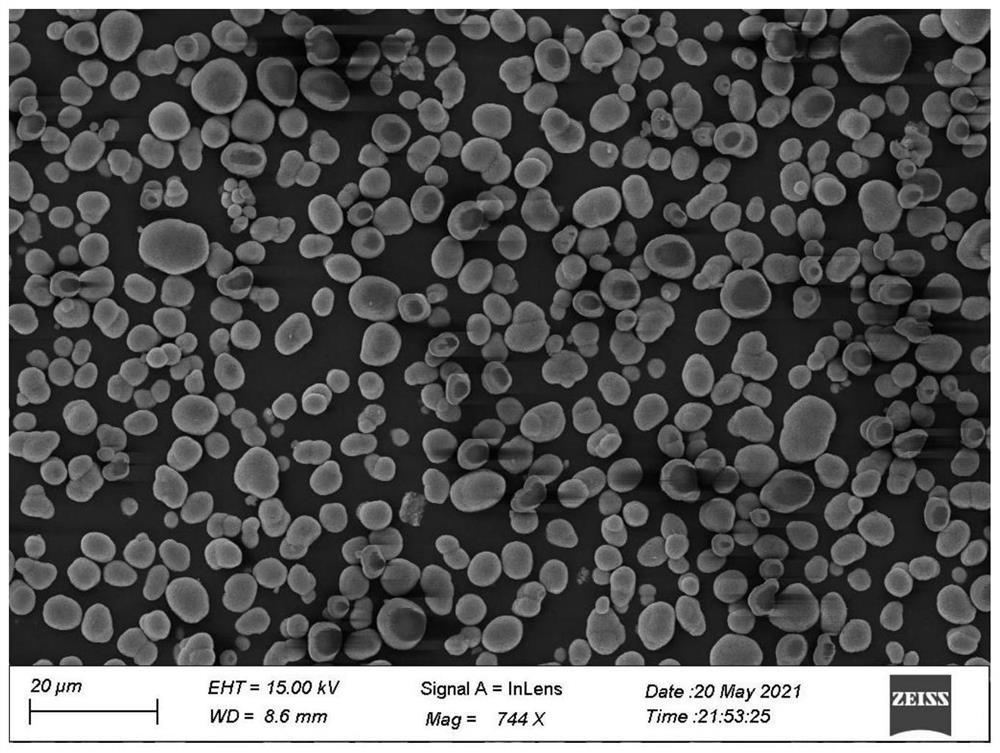

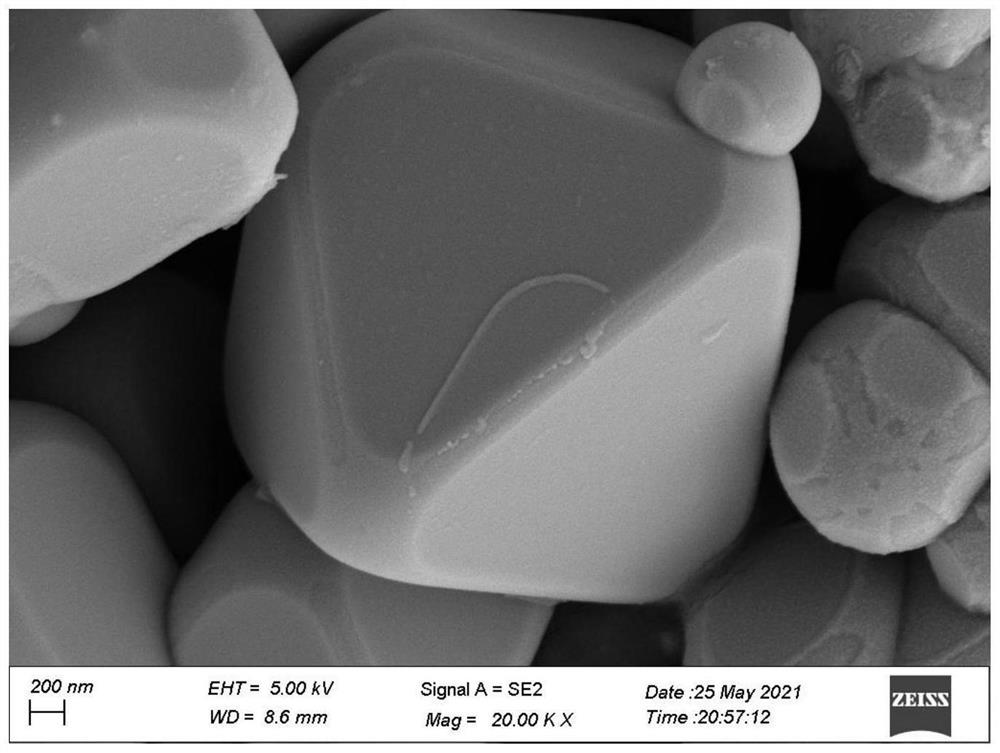

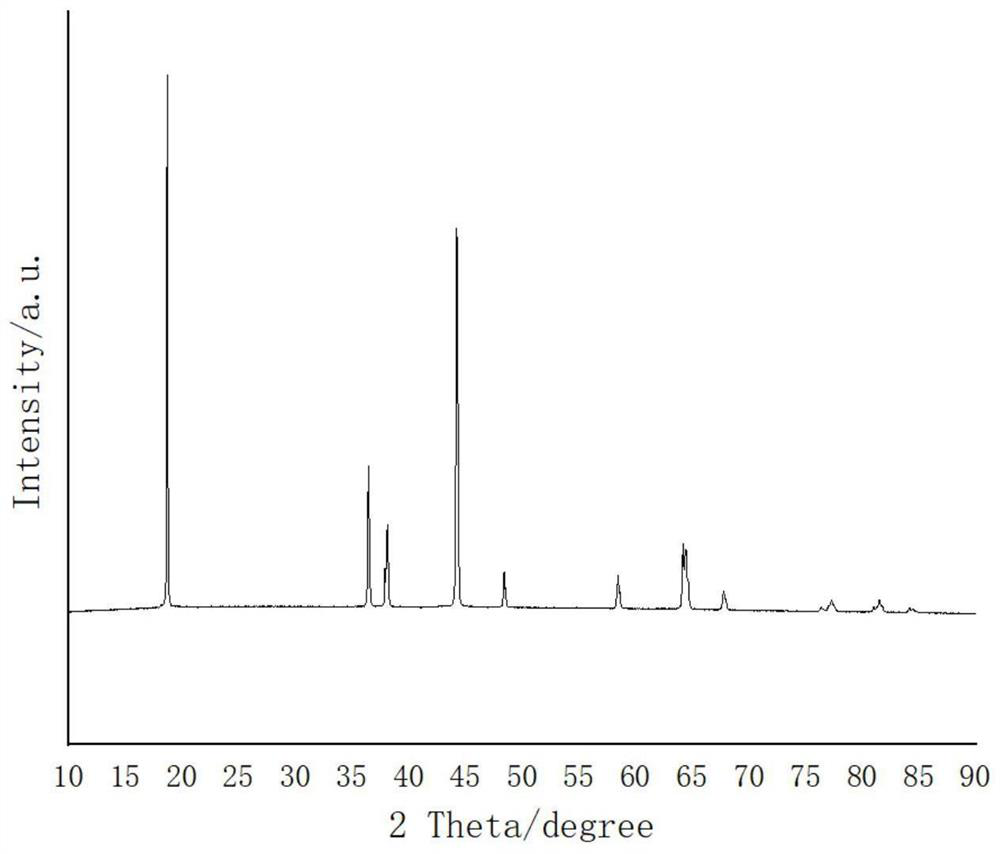

[0029] 1. Synthesize the nickel-rich cathode material precursor by co-precipitation method, prepare a certain amount of nickel sulfate, magnesium sulfate, titanium sulfate, and titanium sulfate into a 3mol / L solution, where Ni:Mg:Fe:Ti=91:3:3 : 3, configure 2mol / L sodium hydroxide solution, 1.5mol / L ammonia solution, configure sodium hydroxide and ammonia water mol ratio to be the mixed solution of 1:2, and drop jointly in the reactor, control pH value to be 10 ±0.2, stirred at 50°C for 15h, washed and filtered, dried at 110°C for 12h, and the particle size distribution was D 50 = 1 ~ 8μm Ni 0.91 Mg 0.03 Fe 0.03 Ti 0.03 (OH) 2 Precursor, its SEM test picture is as follows figure 1 .

[0030] 2. Weigh a certain amount of the precursor in step 1, add lithium hydroxide according to the molar ratio Li / (Ni+Mg+Fe+Ti)=0.8, according to the mass ratio (precursor+lithium source) / molten salt=1, Add the molten salt sodium sulfate, and mix evenly; first keep it warm at 400°C for 8h...

Embodiment 2

[0034] 1. Synthesize the nickel-rich cathode material precursor by co-precipitation method, prepare a certain amount of nickel sulfate, magnesium sulfate, titanium sulfate, and titanium sulfate into a 3mol / L solution, where Ni:Mg:Ti=90:5:5, configure 2mol / L sodium hydroxide solution, 1.5mol / L ammonia solution, prepare a mixed solution with a molar ratio of sodium hydroxide and ammonia water of 1:2, and add them dropwise into the reaction kettle to control the pH value to 10±0.2, 50 Stir at ℃ for 15h, wash and filter, and dry at 110℃ for 12h to obtain a particle size distribution of D 50 = 1 ~ 8μm Ni 0.9 Mg 0.05 Ti 0.05 (OH) 2 Precursor.

[0035] 2. Weigh a certain amount of the precursor in step 1, add lithium hydroxide according to the molar ratio Li / (Ni+Mg+Ti)=0.8, and add molten Salt and sodium sulfate, mix evenly; first keep warm at 400°C for 8h, then heat up to 900°C for 20h, and the heating rate is 10°C / min. After washing and filtering, dry at 110°C for 12 hours. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com