Method for efficiently removing molybdenum based on extraction-precipitation combination

An extraction and high-efficiency technology, applied in the field of wet tungsten metallurgy, can solve the problems of environmental pollution, great impact on the operating environment, odor of sec-octanol, etc., and achieves the effect of wide adaptability and good impurity removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

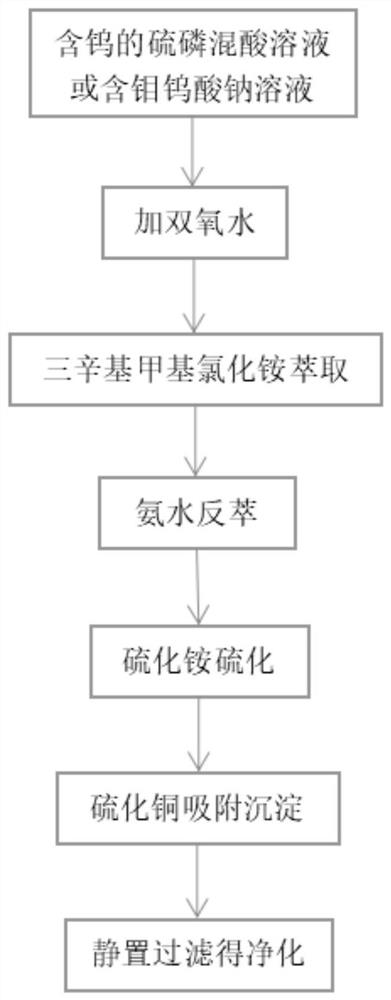

Method used

Image

Examples

Embodiment 1

[0026] A method for efficiently removing molybdenum based on extraction-precipitation, comprising the following steps:

[0027] (1) Prepare organic phase: take trioctylmethyl ammonium chloride as extractant, tributyl phosphate as cosolvent, sulfonated kerosene as diluent mix, stir to form extraction organic phase, wherein extractant, cosolvent and The volume ratio of diluent is 1:1:3;

[0028] (2) organic phase transformation; organic phase is carried out transformation treatment, at first with the H of 3mol / L 2 SO 4 Treat the organic phase with solution for 3-5 times, then treat the organic phase with 2mol / L NaOH solution for 3-5 times, and then use 1mol / L NaHCO 3 The solution was treated for 3-5 times, and finally treated with 2mol / L NaOH solution for 3-5 times, and the aqueous phase was treated with Cl - When the concentration is less than 0.1g / L, the organic phase transformation is complete, that is, CO 3 2- type extractant; where H 2 SO 4 solution, NaOH solution an...

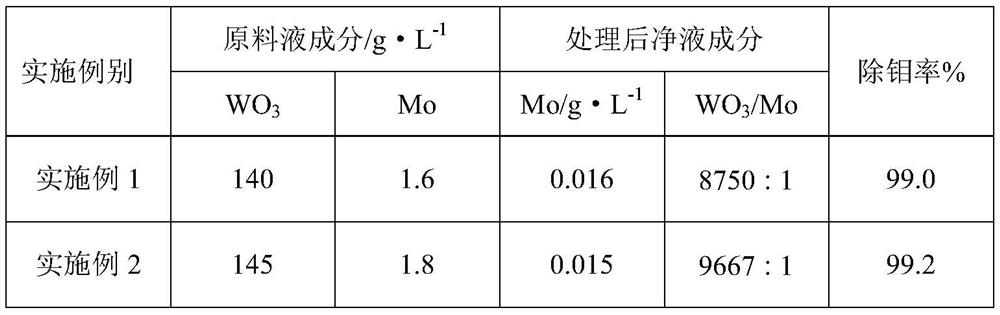

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is that extraction process and precipitation remove molybdenum process:

[0034] Extraction: Take 10L of molybdenum-containing sodium tungstate solution, add 1L of 1mol / L hydrogen peroxide, stir and heat to 80°C, keep the temperature for 1h; adjust the concentration of tungsten trioxide to ≤150g / L, the concentration of sulfuric acid to less than 2mol / L, and pH≤2, Extract with the transformed organic phase extractant prepared above, and keep the reaction pH ≤ 2 at a ratio of O / A of 1:3, so that the tungstate solution to be treated and the extractant are in contact with the extractant for 10 minutes at room temperature, and after two stages After the above extraction, the ammonia solution is used as the stripping agent, and the organic phase is stripped at normal temperature. The concentration of the ammonia solution is 2-4mol / L, and the phase flow rate is 1-2L / min, so as to obtain the stripping solution with low molybde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com