Iron-based amorphous magnetically soft alloy magnetic powder core with organic-inorganic mixed coating

An iron-based amorphous and soft magnetic alloy technology, which is applied in the direction of inorganic materials, magnetic materials, magnetic objects, etc., can solve the problems of alloy difficulty, decrease in magnetic permeability and mechanical properties, and reduce the saturation magnetic induction intensity of alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

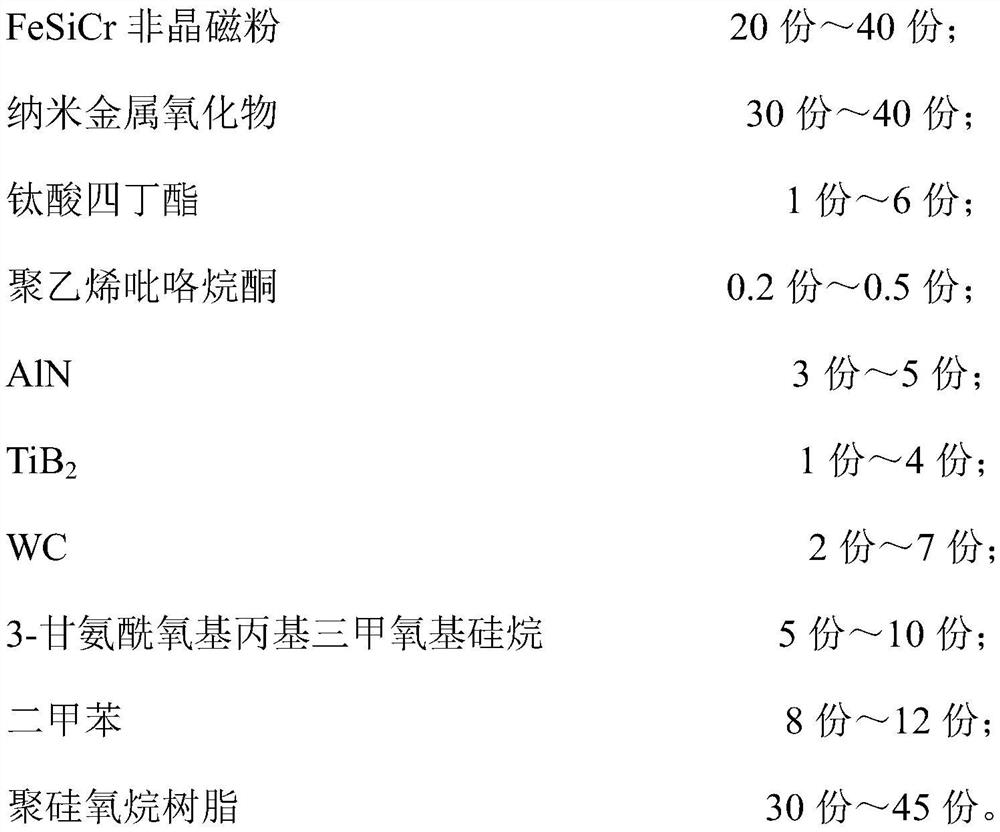

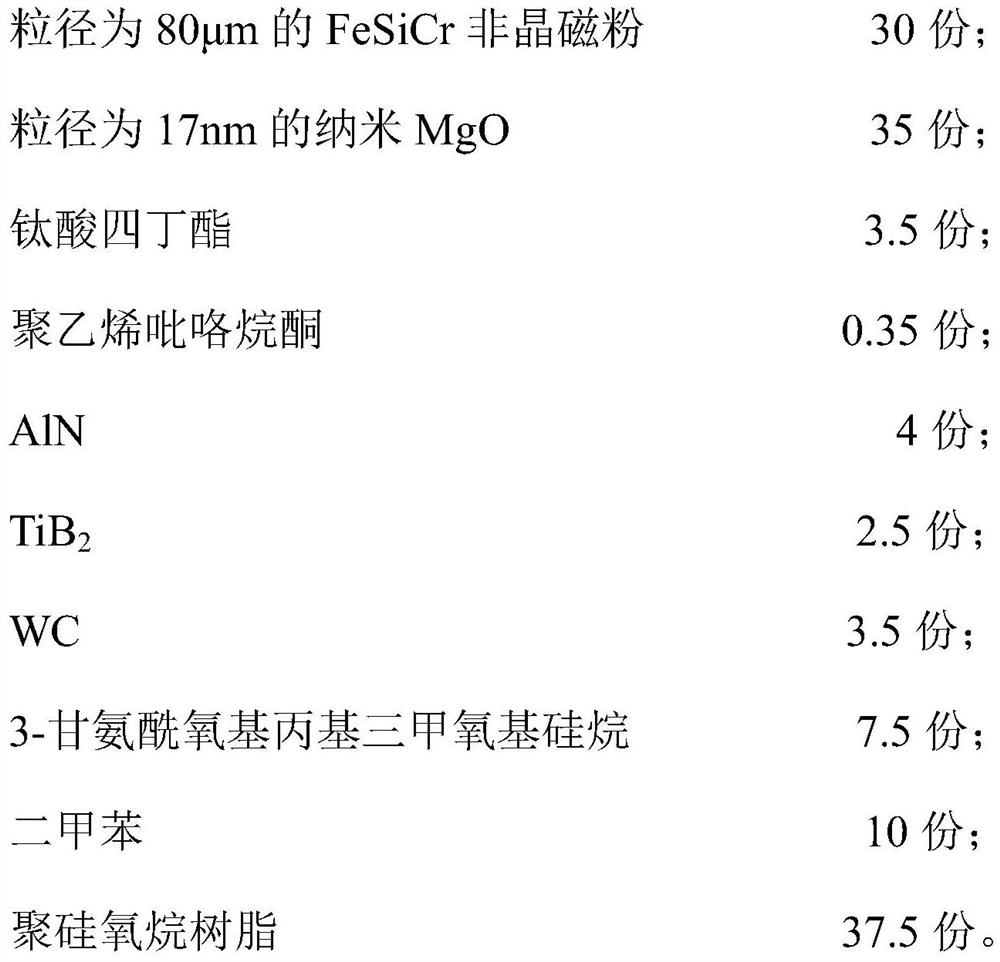

[0033] This embodiment provides an organic-inorganic hybrid coated iron-based amorphous soft magnetic alloy magnetic powder core. The raw materials for the preparation of the magnetic powder core include the following components in parts by weight:

[0034]

[0035] This embodiment also provides a method for preparing the above-mentioned iron-based amorphous soft magnetic alloy magnetic powder core with organic-inorganic hybrid coating, including the following steps:

[0036] 1) Add 0.35 parts of polyvinylpyrrolidone into the 40ml of absolute ethanol, and mix evenly with 30KHz ultrasonic waves;

[0037] 2) Transfer the mixed solution obtained in the step 1) to a three-necked bottle, and add 30 parts of FeSiCr amorphous magnetic powder with a particle size of 80 μm and 3.5 parts of tetrabutyl titanate at 35 °C at 150 rpm Stir for 30min;

[0038] 3) In the mixed solution that described step 2) obtains, add the particle diameter of 35 parts to be the nano-MgO of 17nm, the AlN...

Embodiment 2

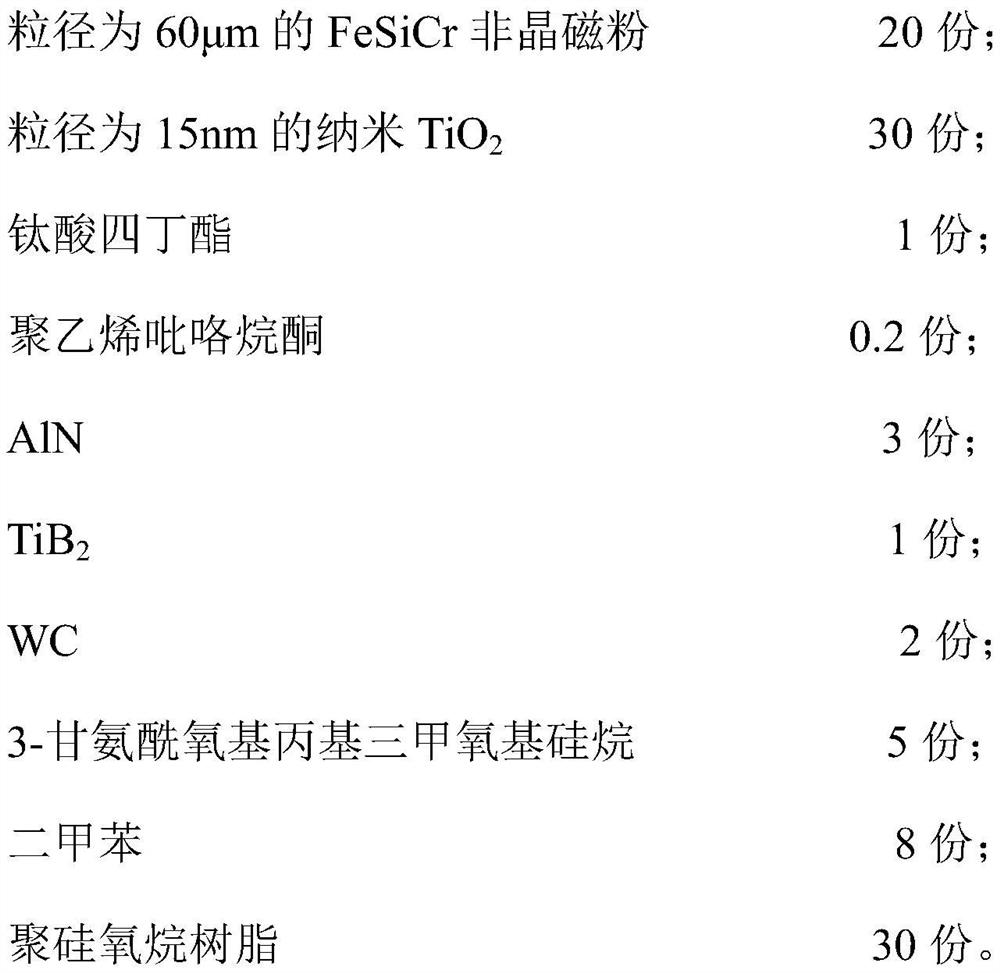

[0046] This embodiment provides an organic-inorganic hybrid coated iron-based amorphous soft magnetic alloy magnetic powder core, = the raw material for the preparation of the magnetic powder core, including the following components in parts by weight:

[0047]

[0048] This embodiment also provides a method for preparing the above-mentioned iron-based amorphous soft magnetic alloy magnetic powder core with organic-inorganic hybrid coating, including the following steps:

[0049] 1) Add 20 parts of polyvinylpyrrolidone into the 30ml of absolute ethanol, and use 20KHz frequency ultrasonic mixing;

[0050] 2) Transfer the mixed solution obtained in step 1) to a three-neck flask, and add 20 parts of FeSiCr amorphous magnetic powder with a particle size of 60 μm and 1 part of tetrabutyl titanate to it and stir at 120 rpm for 20 minutes at 30°C ;

[0051] 3) in the mixed solution that step 2) obtains, add the particle diameter of 30 parts to be the nanometer TiO of 15nm 2 , 3 ...

Embodiment 3

[0059] This embodiment provides an organic-inorganic hybrid coated iron-based amorphous soft magnetic alloy magnetic powder core. The raw materials for the preparation of the magnetic powder core include the following components in parts by weight:

[0060]

[0061] This embodiment also provides a method for preparing the above-mentioned iron-based amorphous soft magnetic alloy magnetic powder core with organic-inorganic hybrid coating, including the following steps:

[0062] 1) Add 0.5 parts of polyvinylpyrrolidone into the 50ml of absolute ethanol, and mix evenly with 40KHz ultrasonic waves;

[0063] 2) Transfer the mixed solution obtained in step 1) to a three-neck flask, and add 40 parts of FeSiCr amorphous magnetic powder with a particle size of 100 μm and 6 parts of tetrabutyl titanate to it, and stir at 180 rpm for 40 minutes at 40 ° C ;

[0064] 3) in the mixed solution that step 2) obtains, add the particle diameter of 40 parts to be the nanometer ZrO of 20nm 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com