Corrosion-resistant conductive coating on surface of magnesium alloy and preparation method of corrosion-resistant conductive coating

A conductive coating and magnesium alloy technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problem that the protective coating cannot meet the requirements of corrosion resistance and conductivity at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

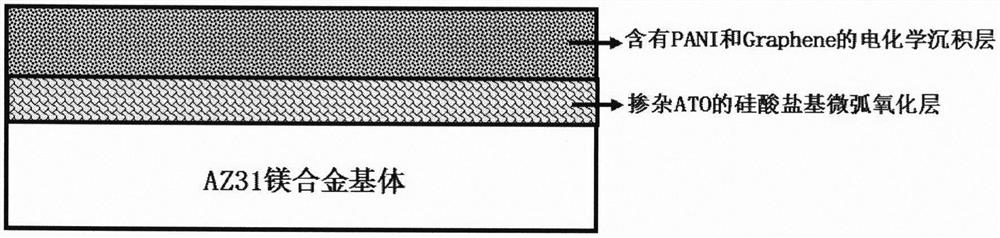

[0034] A kind of magnesium alloy surface corrosion-resistant conductive coating and preparation method thereof of the present invention, concrete implementation of this preparation method has the following steps:

[0035] The first step: Mechanical grinding to prepare the pre-treated surface

[0036] In order to facilitate the test, the magnesium alloy block, plate or bar was cut into 120mm×120mm×3mm square pieces or Φ100×3mm discs with a wire cutting machine, and mechanically ground with water sandpaper to remove surface scale and impurities. Ultrasonic cleaning in acetone and absolute ethanol for 10 min, and drying with cold air.

[0037] Step 2: Preparation of pre-treated surface by friction stir processing

[0038] Use a gantry-type friction stir welding machine to perform friction stir processing on the pretreated surface of the magnesium alloy obtained in the first step, select a cylindrical needle-free stirring head, and the shoulder is a double-ring structure, and the...

Embodiment 1

[0048] The first step: Mechanical grinding to prepare the pre-treated surface

[0049] For the convenience of the test, the AZ31 magnesium alloy block was cut into square pieces of 120mm×120mm×3mm by a wire cutting machine, mechanically ground with water sandpaper to remove surface scale and impurities, and ultrasonically cleaned in acetone and absolute ethanol for 10 minutes respectively. Air dry.

[0050] Step 2: Preparation of pre-treated surface by friction stir processing

[0051] The gantry friction stir welding machine is used to perform friction stir processing on the pretreated surface of AZ31 magnesium alloy obtained in the first step. The cylindrical needleless stirring head is selected, and the shoulder is a double ring structure. The diameter of the shoulder is 8mm, and the shoulder is pressed down. The volume is 0.1 mm, the rotation speed of the stirring head is 1400 rpm, the translational speed of the stirring head is 250 mm / min, and the distance between passes...

Embodiment 2

[0068] The first step: Mechanical grinding to prepare the pre-treated surface

[0069] For the convenience of the test, the ZK60 magnesium alloy plate was cut into square pieces of 120mm×120mm×3mm with a wire cutting machine, mechanically ground with water sandpaper to remove surface scale and impurities, ultrasonically cleaned in acetone and absolute ethanol for 10 minutes, and cold air blow dry.

[0070] Step 2: Preparation of pre-treated surface by friction stir processing

[0071] The gantry friction stir welding machine is used to perform friction stir processing on the pretreated surface of the ZK60 magnesium alloy obtained in the first step. The cylindrical needleless stirring head is selected, and the shoulder is a double ring structure. The diameter of the shoulder is 9mm, and the shoulder is pressed down. The volume is 0.1 mm, the rotation speed of the stirring head is 1600 rpm, the translational speed of the stirring head is 270 mm / min, and the distance between pas...

PUM

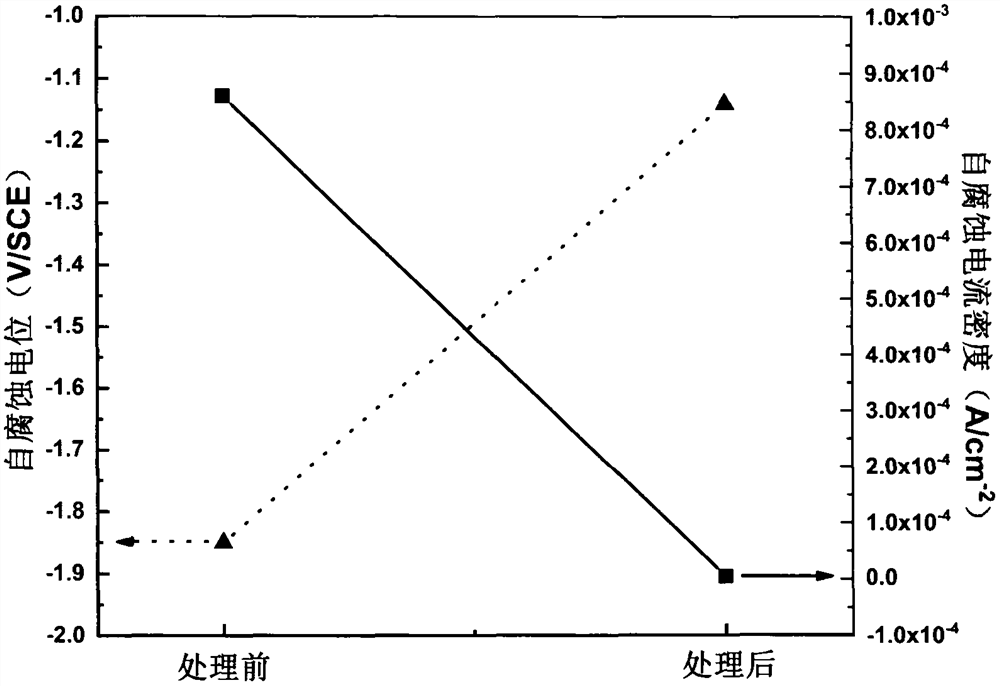

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com