Preparation method and application of metal organic framework MIL-101-V with three-dimensional mesoporous structure

A metal-organic framework, three-dimensional mesoporous technology, applied in structural parts, electrical components, electrochemical generators, etc., can solve the problem of unfavorable rate performance and long-cycle stability of zinc-ion batteries, difficult high-rate charge-discharge cycle performance, secondary Due to the large size of manganese oxide particles, the effects of low cost of raw materials, improved electrochemical performance, and simple and easy-to-operate synthesis methods are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method of preparing a metal organic skeleton MIL-101-V in a three-dimensional media structure, according to the following steps:

[0029] S1: 30 ml of deionized water and 30 ml of water and 30 ml of water and 30 ml of water and 30 ml of absolute ethanol are mixed with a mixed solvent by magnetic stirring, and the vanadium chloride and the terephthalic acid monomer are mixed in the mixed solvent in the mixed solvent, and 25% by weight Ammonia was 6 ml to add a mixed solution.

[0030] S2: The mixed solution was stirred for 30 min and then transferred to a 100 mL autoclave, water heat treatment at a temperature of 180 ° C for 20 hours, and vanadium ions in the vanadium chloride and p-oslated formation were formed. Finally, it was washed three times with deionized water and ethanol. After the washing was completed, it was dried at 60 ° C for 24 hours to obtain a three-dimensional media metal organic skeleton MIL-101-V composite material, and then grounded and weighed product...

Embodiment 2

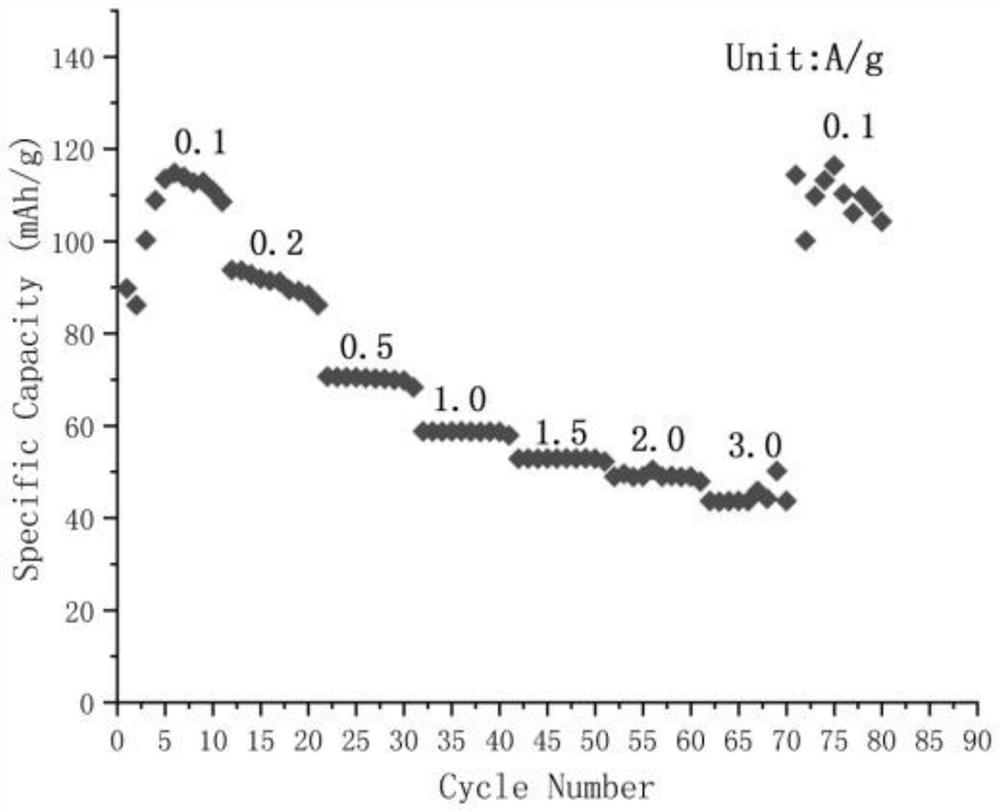

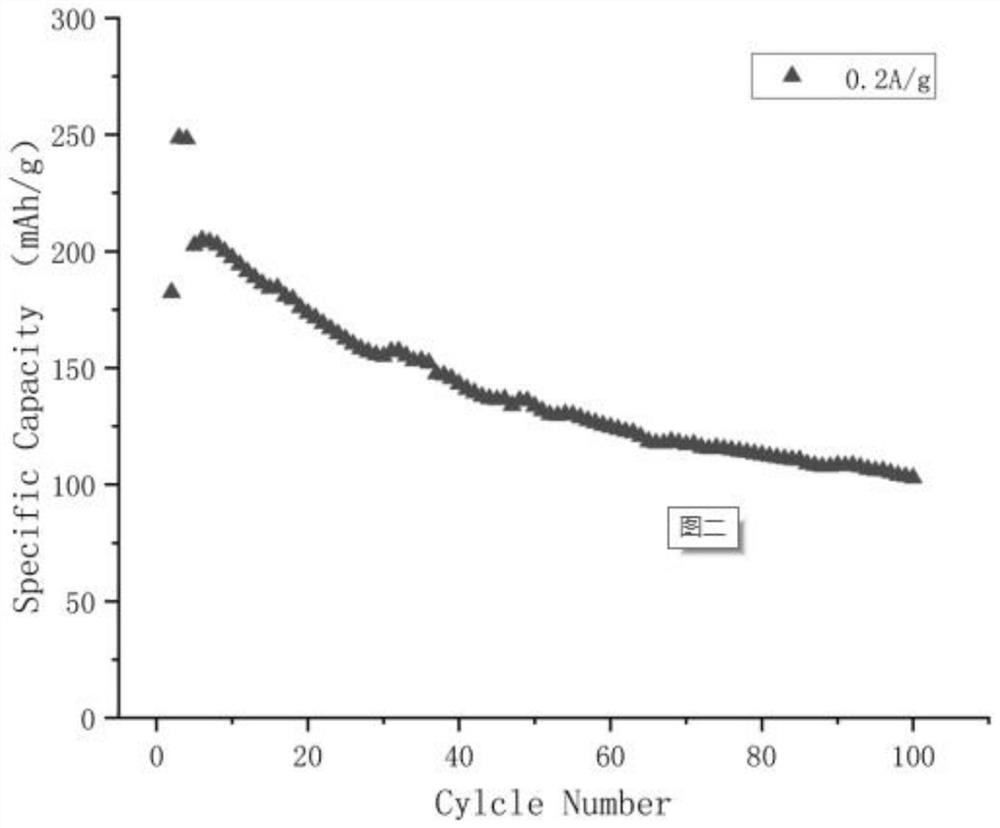

[0033] Metal organic skeleton MIL-101-V composites using the above three-dimensional media

[0034] At normal temperature, 0.04 g of the conductive carbon black was added to 0.8 g of 2.5 wt% polyvinylidene fluoride N-methylpyrrolidone solution to obtain a mixed solution. After 20 min, a 0.14 g of a three-dimensional diaphragm structure metal organic skeleton MIL-101-V composite material was added to the above mixed solution, and stirred for 4 hours to give a mixed uniform positive slurry. After stirring, the resulting positive electrode slurry is evenly applied to the surface of the titanium foil. After drying the coated titanium foil, a small circle having a diameter of 14 mm was cut, ie the zinc ion battery positive electrode.

[0035] A zinc ion battery was produced by producing a zinc ion battery using the above method

[0036] The zinc foil is also cut into a 14 mm small circle as a battery negative electrode material, and a 16 mm glass filter paper is used as a positive and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com