Copper-nickel-tin-silicon alloy and preparation method and application thereof

A copper-nickel-tin-silicon alloy technology, applied in the field of alloys, can solve the problems of insufficient alloy hardness, low content of tin element, and limited precipitated phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a method for preparing the copper-nickel-tin-silicon alloy described in the above technical solution, comprising the following steps:

[0039] Melting alloy raw materials to obtain alloy liquid, and pouring the alloy liquid to obtain cast alloy;

[0040] performing hot rolling and solution treatment on the as-cast alloy in sequence to obtain a solid solution alloy; the temperature of the solution treatment is 725-875°C;

[0041] The solid solution alloy is subjected to cold rolling and aging treatment in sequence to obtain a copper-nickel-tin-silicon alloy; the temperature of the aging treatment is 250-450° C.

[0042] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0043] In the invention, alloy raw materials are smelted to obtain alloy liquid, and the alloy liquid is poured to obtain cast alloy.

[0044] In the present invent...

Embodiment 1

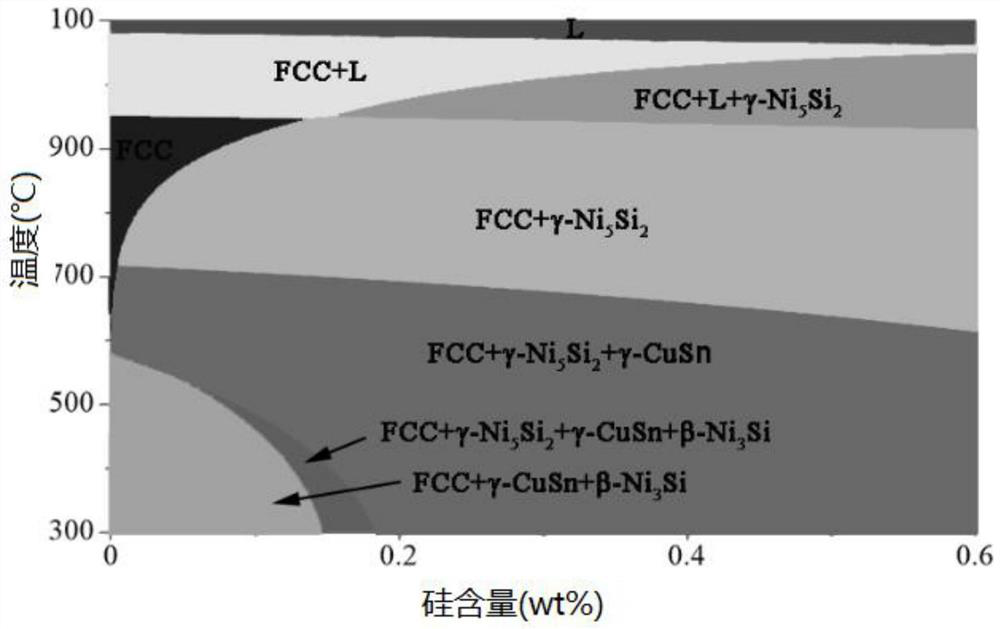

[0055] The chemical composition design of the copper-nickel-tin-silicon alloy is carried out using Pandat software, open the Pandat software, select Cu, Ni, Sn, Si four elements, set the Ni mass percentage content as 6%, the Sn mass percentage content as 6%, Si is a variable, and the balance is Cu; set the calculation temperature to 300-1200°C; calculate the phase diagram and output the results, the simulated phase diagram results of Cu-6Ni-6Sn-xSi alloy are as follows figure 1 , where FCC stands for face-centered cubic structure and L stands for liquid phase. Depend on figure 1 It can be seen that when the Si content exceeds 0.15wt%, the alloy will produce γ-Ni during solidification 5 Si 2 phase, and exists with the FCC matrix and L, which can theoretically explain the γ-Ni 5 Si 2 It is the primary phase, and it can be predicted that it cannot be eliminated by solution treatment.

[0056] according to figure 1 It is determined that the alloy composition is 6wt% Ni, 6wt%...

Embodiment 2~5

[0064] The copper-nickel-tin-silicon alloy was prepared according to the method of Example 1, and the preparation conditions of Examples 2-5 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com