Phase field dynamics method for simulating bifurcation growth process of titanium alloy alpha lamella

A growth process, titanium alloy technology, applied in the field of metallurgical casting, can solve problems such as complex bifurcation growth characteristics, and achieve the effect of avoiding limitations, improving and optimizing structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

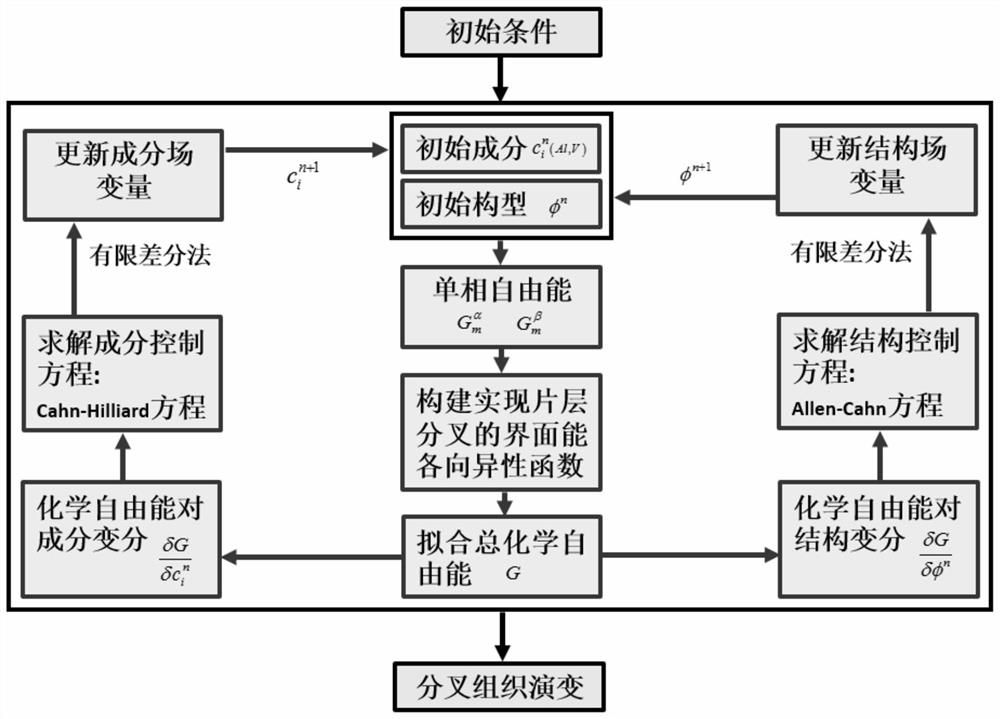

Method used

Image

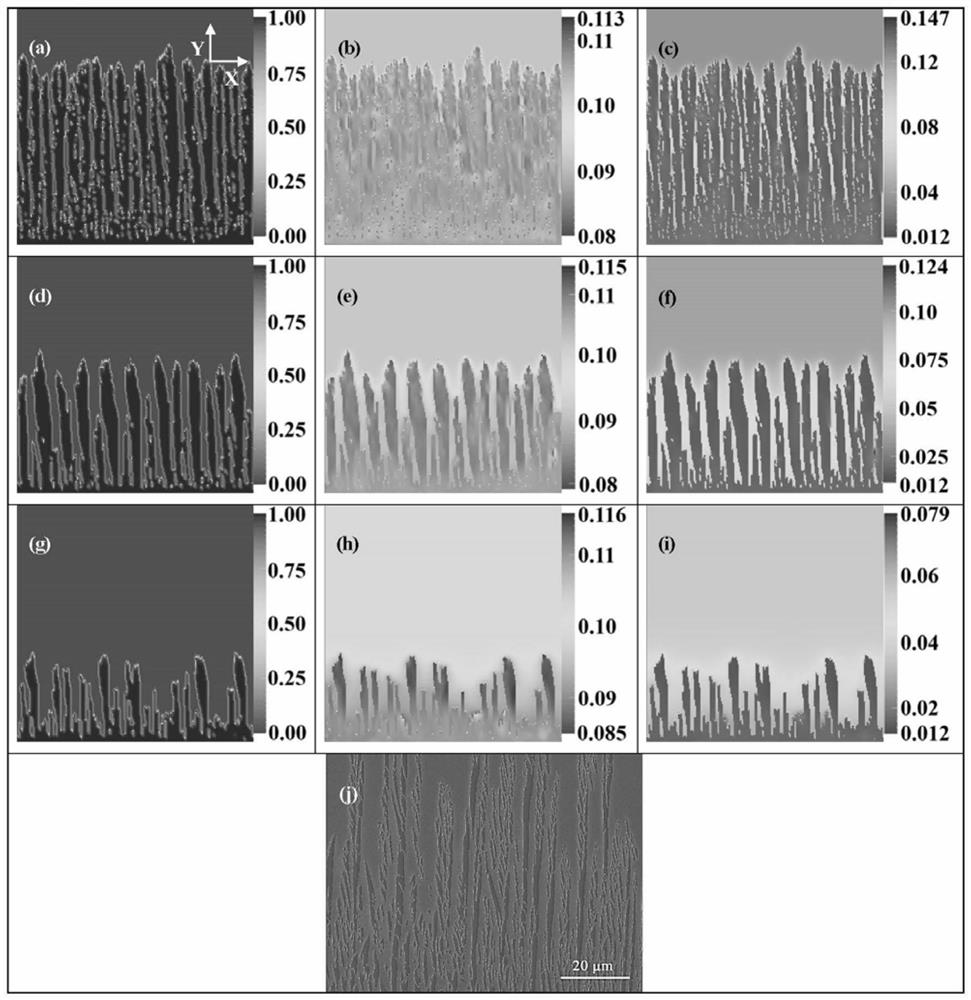

Examples

Embodiment

[0050] Taking Ti-6Al-4V alloy as an example, the phase field dynamics method for simulating the bifurcation growth process of titanium alloy α sheet is:

[0051] (1) Thermodynamics and Equilibrium Components

[0052] First, according to the phase transition temperature of the Ti-6Al-4V alloy, the Gibbs free energy data of the α and β phases at the target temperature were obtained by thermodynamic calculations, and the local free energy densities of the α and β phases of the alloy system were constructed.

[0053] The solution-type local free energy density expression is as follows:

[0054]

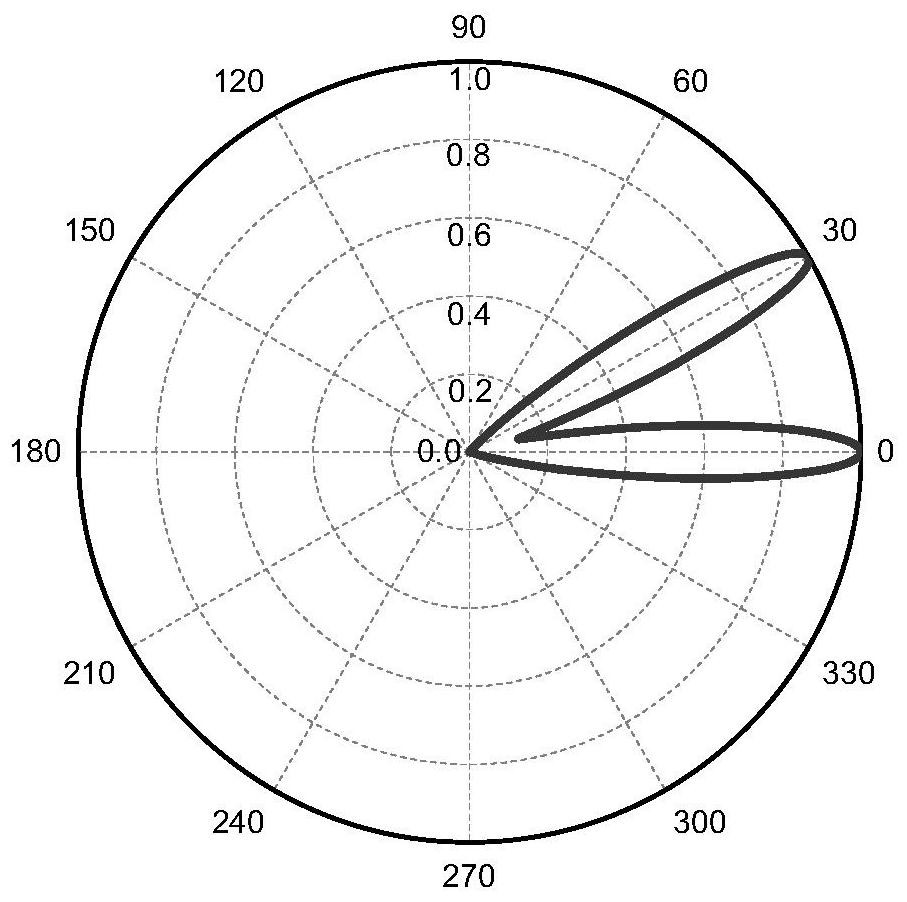

[0055] where h(φ)=φ 3 (6φ 2 -15φ+10) is an interpolation function used to connect the free energy curves of the β and α phases; T represents the system temperature in K; c i Indicates the alloy element composition, i=Al and V, the unit is at.%; φ indicates the structural field variable, no unit; and are the equilibrium molar free energies of the α and β phases, unit J / mol, which...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap