Preparation method of hydrogen-containing titanium alloy wire for additive manufacturing

A titanium alloy wire and additive manufacturing technology, which is applied in the field of titanium alloys, can solve problems such as difficult processing, poor formability, and lower phase transition temperature, so as to improve internal structure, optimize hot forming performance, and reduce phase transition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

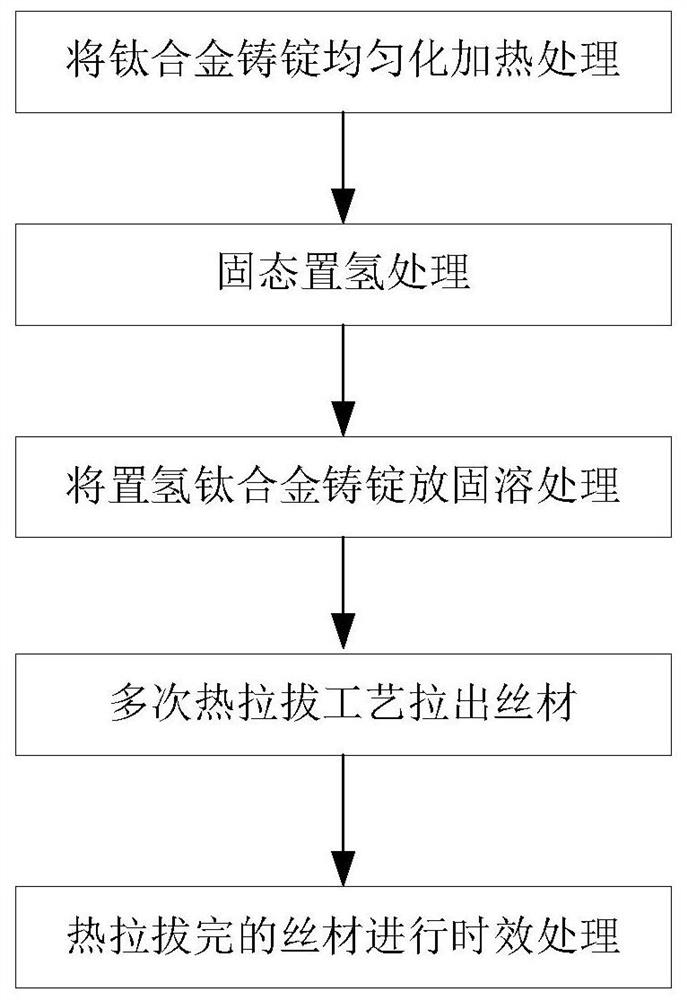

[0035] combine figure 1 As shown, the present invention proposes a method for preparing a hydrogen-containing titanium alloy wire for additive manufacturing, including:

[0036] Step 1. Homogenize and heat treat the titanium alloy ingot, which can be a titanium alloy rod with a certain length and diameter or a titanium alloy ingot of other shapes, including but not limited to a rectangle;

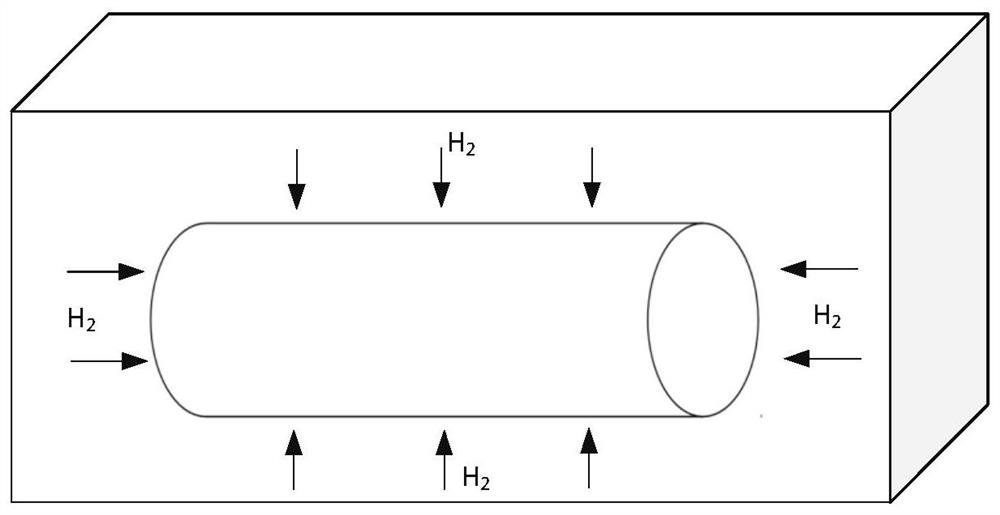

[0037] Step 2, putting the titanium alloy ingot into a closed tubular hydrogenation heating furnace, and injecting hydrogen into a hydrogenation treatment in a vacuum environment to obtain a hydrogenation titanium alloy ingot;

[0038] Step 3, putting the hydrogenated titanium alloy ingot into a heat treatment furnace for solid solution treatment;

[0039] Step 4, subjecting the titanium alloy ingot after the solution treatment to a hot drawing process with a preset deformation amount, and cooling in the furnace after drawing to obtain a titanium alloy wire; and

[0040] Step 5: Perform a...

Embodiment 1

[0059] [Implementation 1] Adopt the process of "hydrogen setting + solid solution + room temperature drawing + aging"

[0060] 1) The TC4 titanium alloy ingot is subjected to hydrogenation treatment, specifically, the TC4 titanium alloy ingot is placed in a tubular hydrogenation furnace, and the vacuum is evacuated to 1.5*10 -3 Pa, heat at a rate of 10-20°C / min to 700°C-800°C, hold for 10-30min, fill in 0.8% hydrogen according to the weight percentage of the titanium alloy ingot, hold for 2h, and then heat at 5-15°C / min min is cooled to room temperature to obtain a hydrogen-containing titanium alloy ingot; as image 3 shown;

[0061] 2) Perform solid solution treatment on the above-mentioned hydrogenated titanium alloy ingot, put the titanium alloy ingot into a heat treatment furnace, and heat it to T at a speed of 10-20°C / min. β ℃+10℃, keep warm for 20min~40min, then quench and cool to room temperature;

[0062] 3) The hydrogenated titanium alloy ingot is peeled to remove ...

Embodiment 2

[0065] [Implementation 2] Adopt the process of "hydrogen setting + solid solution + hot drawing + aging"

[0066] 1) The TC4 titanium alloy ingot is peeled to remove surface cracks and folds, one end is rounded, and hydrogen treatment is carried out. Specifically, the TC4 titanium alloy ingot is placed in a tubular hydrogen furnace and vacuumed to 1.5*10 -3 Pa, heat at a rate of 10-20°C / min to 700°C-800°C, hold for 10-30min, fill in 0.8% hydrogen according to the weight percentage of the titanium alloy ingot, hold for 2h, and then heat at 5-15°C / min min is cooled to room temperature to obtain hydrogen-containing titanium alloy ingot;

[0067] 2) Perform solid solution treatment on the above-mentioned hydrogenated titanium alloy ingot, put the titanium alloy ingot into a heat treatment furnace, and heat it to T at a speed of 10-20°C / min. β ℃+10℃, keep warm for 20min~40min, then quench;

[0068] 3) cast hydrogenated titanium alloy ingot at T β -50℃~T β -30°C temperature inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com