Low-VOC organic-solvent-free heat-resistant water-based coating and high-temperature-resistant and corrosion-resistant coating prepared from coating

An organic solvent and hot water resistance technology, applied in the field of high temperature and corrosion resistant coatings and heat resistant coatings, can solve the problems of large pollution, residual surfactant cracking products, large particle size, etc., and reach the film-forming baking temperature Low, reduced development workload, excellent paint film performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A kind of preparation method of engineering plastic dispersion liquid, concrete steps are as follows:

[0089] Step 1. Take 200 parts of chloroform, add 4 parts of sodium dodecanoate, 4 parts of sodium myristate, and 60 parts of PES coarse powder, and stir for 30 minutes until PES is fully dissolved. Add chloroform to the obtained solution to adjust the solution viscosity to 200±10Pa.s.

[0090] Step 2. Stir at a rotational speed of 500 rpm, and at the same time slowly add 300 parts of water, control the addition of water to complete within 5-10 minutes, and obtain an emulsified dispersion of the PES solution.

[0091] Step 3. Set the spray steam temperature to 120°C, the steam flow rate to 100L / min, and the emulsified dispersion liquid flow rate of the PES solution to 100g / min, and quickly remove the chloroform in the dispersion liquid by spray evaporation to obtain a heat-resistant and hydrolysis-resistant PES dispersion liquid .

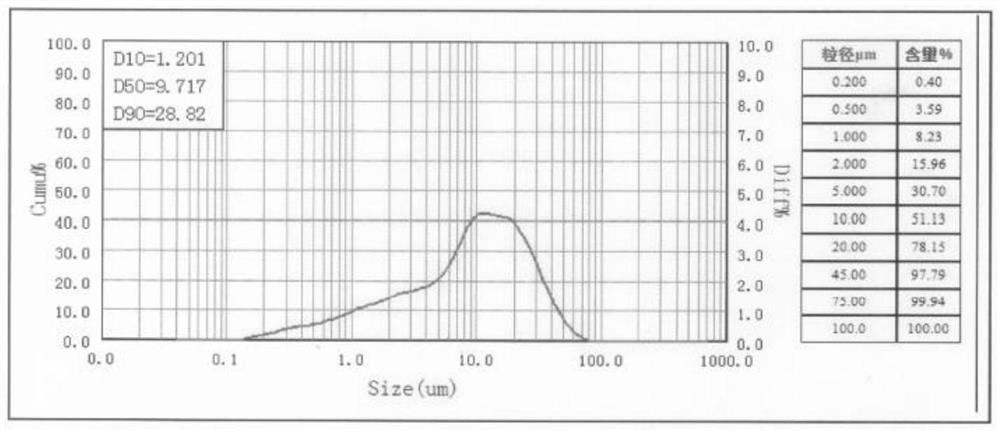

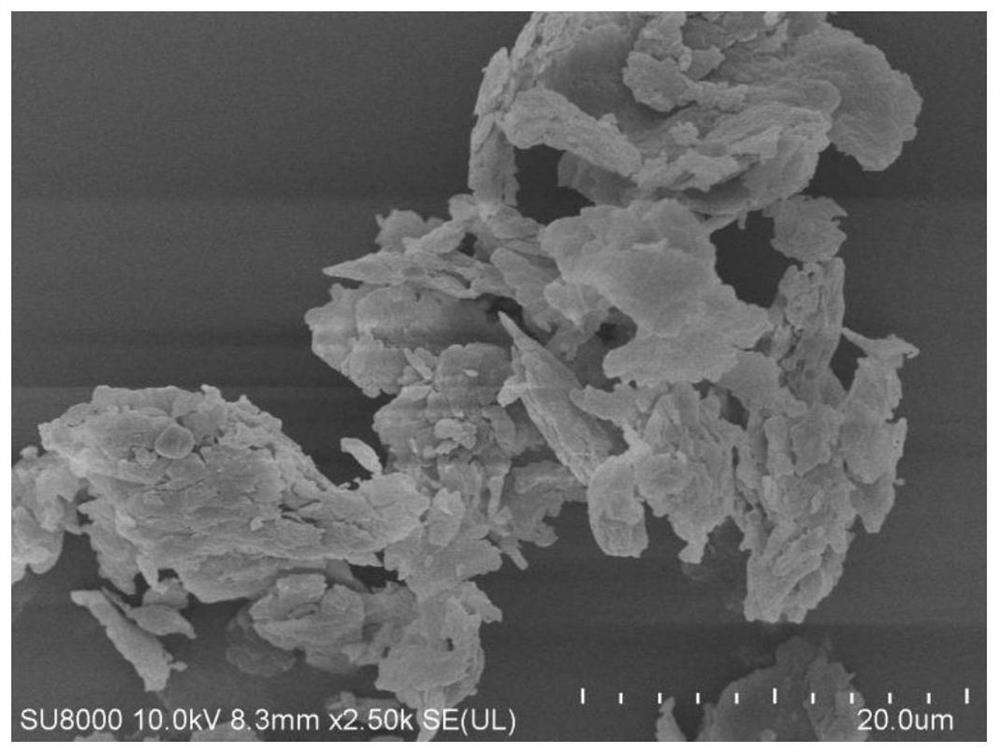

[0092] The resulting PES dispersio...

Embodiment 2

[0097] Step 1. Take 150 parts of chloroform, add 4 parts of sodium dodecanoate, 4 parts of sodium myristate, and 60 parts of PPSU coarse powder, and stir for 30 minutes until PPSU is fully dissolved. Add chloroform to the obtained solution to adjust the solution viscosity to 500±10Pa.s.

[0098] Steps 2 and 3 refer to Example 1.

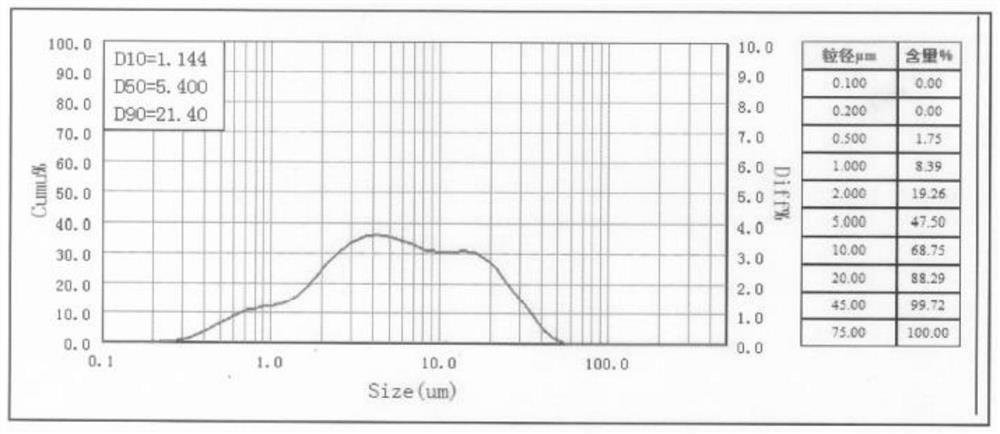

[0099] The obtained PPSU dispersion liquid is taken and detected by a laser particle size analyzer, and the particle size distribution of the obtained material is 0.7-10 μm.

Embodiment 3

[0101] Step 1. Take 200 parts of chloroform, add 4 parts of sodium octadecanoate, 4 parts of sodium hexadecanoate, and 60 parts of PES coarse powder, and stir for 30 minutes until the PES is fully dissolved. Add chloroform to the obtained solution to adjust the solution viscosity to 200±10Pa.s.

[0102] Steps 2 and 3 refer to Example 1.

[0103] The obtained PES dispersion liquid is taken and detected by a laser particle size analyzer, and the particle size distribution of the obtained material is 0.5-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com