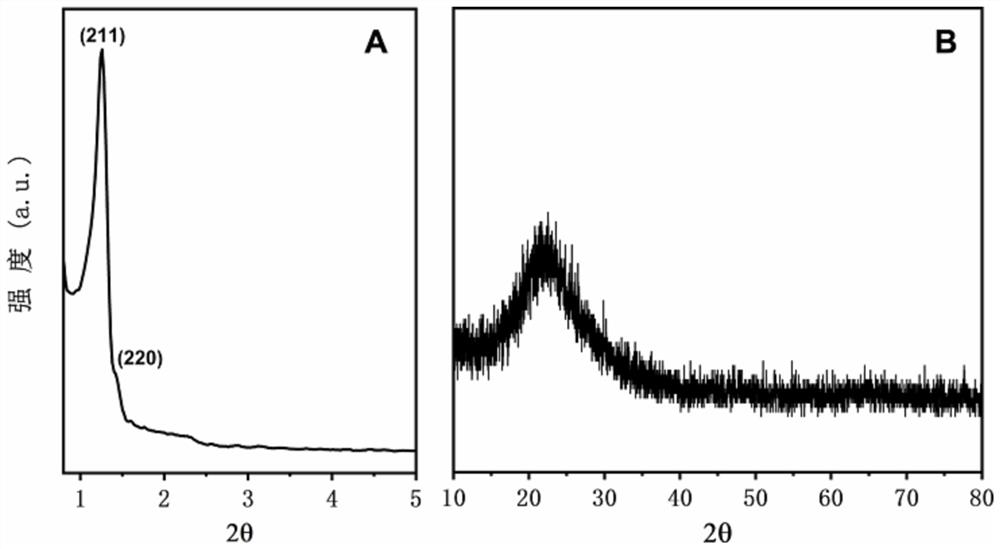

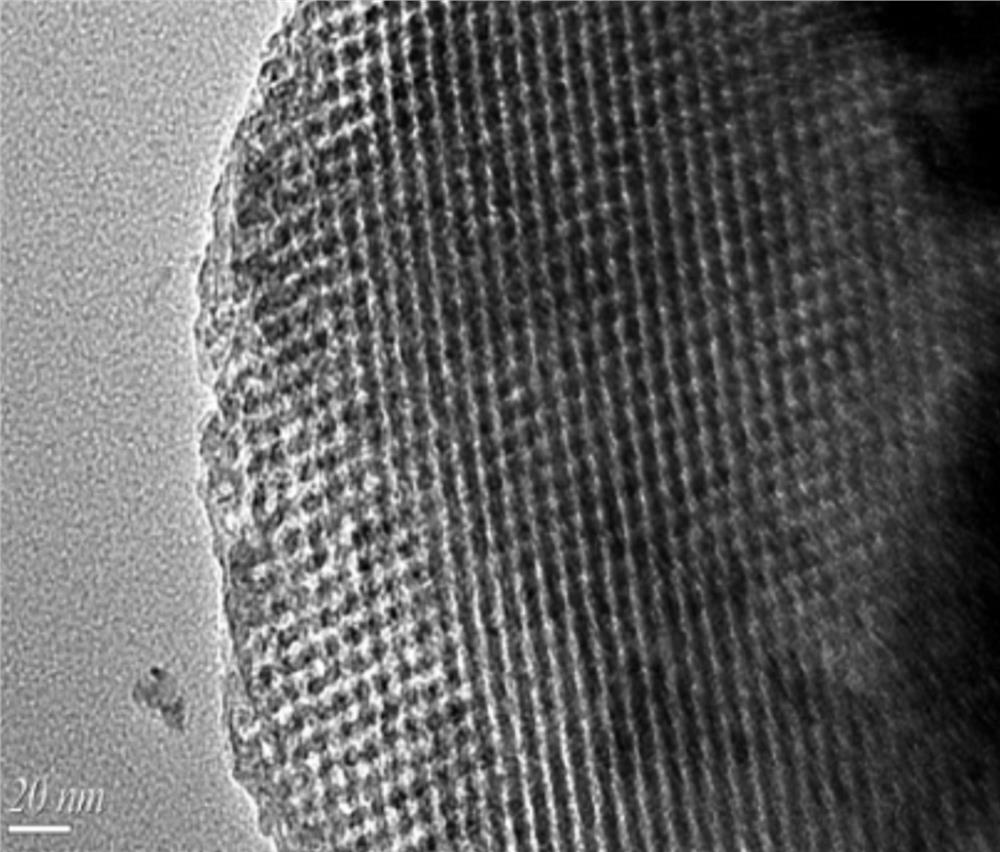

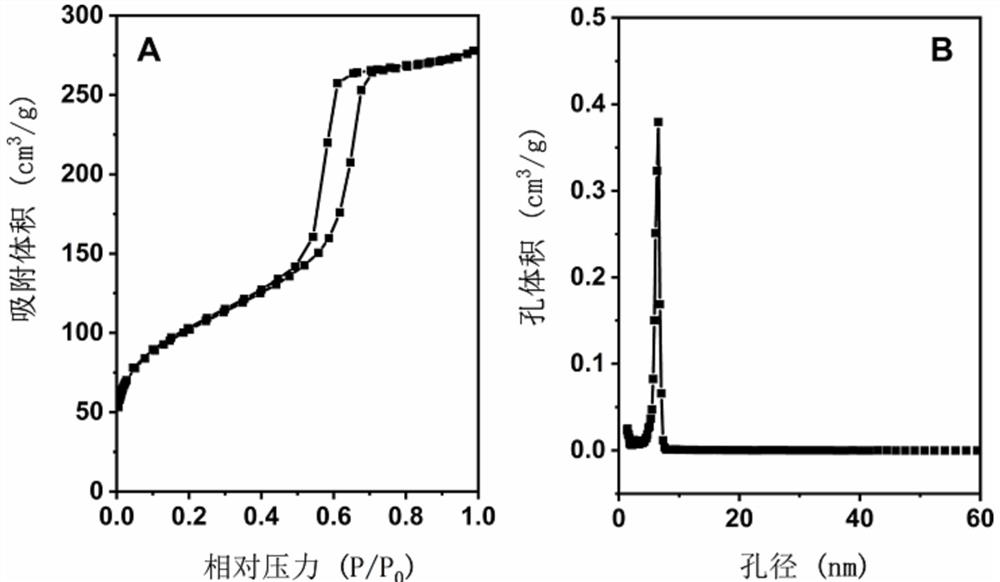

Ordered mesoporous KIT-6 loaded zirconium sulfate-aluminum composite oxide solid acid material, and preparation and application thereof

A KIT-6, aluminum composite technology, applied in the direction of catalyst activation/preparation, biofuel, fatty acid esterification, etc., can solve the problems of low acid content, poor structural thermal stability, and small pore size of solid acid materials, and achieve the preparation method Easy to implement, adjustable coating degree, and controllable surface acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Slowly add 2.0g of n-butanol dropwise into 80mL of 0.5mol / L hydrochloric acid solution dissolved with 3.26g of glacial acetic acid and 2.0g of P123, and after vigorous stirring at 35°C for 6h, add 4.3g of ethyl orthosilicate to the reaction solution , and keep stirring at this temperature for 24h.

[0049] Put the white solid suspension obtained by the above self-assembly in a closed high-pressure reactor, heat it to 140°C for hydrothermal polymerization treatment for 24 hours, take out the reaction product, filter it with suction, wash it, and dry it to prepare the coated surfactant gel A bundle of ordered mesoporous KIT-6 materials is a white solid.

[0050] in N 2 Under the atmosphere, the white solid obtained above was heated to 550° C. for 2 h at high temperature to promote the partial carbonization and shrinkage of the surfactant micelles existing in the KIT-6 mesoporous channels.

[0051] Next, place the carbonized material in 20 mL of an aqueous solution disso...

Embodiment 2

[0067] Slowly add 2.5g of n-butanol dropwise to 65mL of 1.0mol / L hydrochloric acid solution dissolved with 3.0g of glacial acetic acid and 2.5g of P123, and after vigorous stirring at 35°C for 10h, add 3.02g of methyl orthosilicate to the reaction solution , and keep stirring at this temperature for 24h.

[0068]Put the white solid suspension obtained by the above self-assembly in a closed high-pressure reactor, heat it to 120°C for hydrothermal polymerization treatment for 24 hours, take out the reaction product, filter it with suction, wash it, and dry it to prepare the coated surfactant gel A bundle of ordered mesoporous KIT-6 materials is a white solid.

[0069] in N 2 Under the atmosphere, the white solid obtained above was heated to 450° C. for 2 h at a high temperature, and the surfactant micelles existing in the KIT-6 mesoporous channels were partially carbonized and shrunk.

[0070] Next, place the carbonized material in 15 mL of an aqueous solution in which 0.3 mol...

Embodiment 3

[0077] Slowly add 2.0 g of n-butanol dropwise into 80 mL of 2.0 mol / L hydrochloric acid solution in which 0.84 g of citric acid and 2.2 g of P123 are dissolved, stir vigorously at 35°C for 8 hours, then add 0.96 g of white carbon black to the reaction solution, and Stirring was continued at this temperature for 24h.

[0078] Put the white solid suspension obtained by the above self-assembly in a closed high-pressure reactor, heat it to 120°C for hydrothermal polymerization treatment for 24 hours, take out the reaction product, filter it with suction, wash it, and dry it to prepare the coated surfactant gel A bundle of ordered mesoporous KIT-6 materials is a white solid.

[0079] in N 2 Under the atmosphere, the white solid obtained above was heated to 550° C. for 2 h at high temperature to promote the partial carbonization and shrinkage of the surfactant micelles existing in the KIT-6 mesoporous channels.

[0080] Next, the carbonized material was placed in 15 mL of an aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com