Automobile fender material and preparation method thereof

A technology for fenders and automobiles, which is applied in the field of auto parts materials, can solve the problems of high price of fenders, high fender brittleness, easy to break, etc., and achieves the effects of high reproducibility, suitable hardness and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

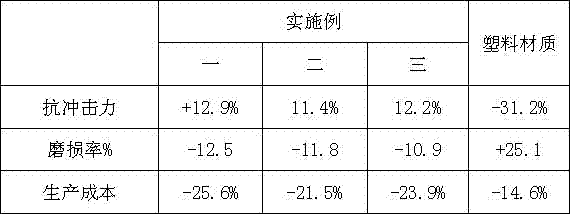

Embodiment 1

[0020] A kind of automobile fender material that the present invention proposes comprises the raw material of following weight parts: 70 parts of waste tires, 20 parts of neoprene raw rubber, 15 parts of polyethylene resins, 4 parts of molybdenum disulfide, 6 parts of sericite powder, 4 parts of oleic acid, 4 parts of silicone oil, 3 parts of dispersant, 1 part of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, 4-benzoyl 0.5 part of oxy-2,2,6,6-tetramethylpiperidine, 0.3 part of anti-aging agent, and 0.3 part of vulcanizing agent.

[0021] Its preparation method comprises the following steps:

[0022] S1. Pretreatment of waste tires and polyethylene resin: Rinse the recovered waste tires with water for 3 times, soak them in ethanol solution for 5-10 minutes, take them out, drain them and dry them at 35°C, and then dry the waste tires The tires are cut and ground in turn to obtain waste tire powder, and then the waste tire powder is passed through a 20-mesh si...

Embodiment 2

[0026] A kind of automobile fender material that the present invention proposes comprises the raw material of following weight parts: 80 parts of waste tires, 15 parts of neoprene raw rubber, 20 parts of polyethylene resins, 6 parts of molybdenum disulfide, 3 parts of sericite powder, 5 parts of oleic acid, 2.5 parts of silicone oil, 3 parts of dispersant, 1.5 parts of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, 4-benzoyl 0.75 parts of oxy-2,2,6,6-tetramethylpiperidine, 0.4 parts of anti-aging agent, and 0.3 parts of vulcanizing agent.

[0027] Its preparation method comprises the following steps:

[0028] S1. Pretreatment of waste tires and polyethylene resin: Rinse the recovered waste tires with water for 3 times, soak them in ethanol solution for 10 minutes, take them out, drain them and dry them at 30°C, and then dry the waste tires one by one Carry out cutting and grinding to obtain waste tire powder, then pass the waste tire powder through a 20-mesh...

Embodiment 3

[0032] A kind of automobile fender material that the present invention proposes comprises the raw material of following weight portion: 50 parts of waste tires, 15 parts of neoprene raw rubber, 10 parts of polyethylene resins, 4 parts of molybdenum disulfide, 3 parts of sericite powder, 2.5 parts of oleic acid, 2.5 parts of silicone oil, 3 parts of dispersant, 1 part of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, 4-benzoyl 0.75 parts of oxy-2,2,6,6-tetramethylpiperidine, 0.1 parts of anti-aging agent, and 0.4 parts of vulcanizing agent.

[0033] Its preparation method comprises the following steps:

[0034] S1. Pretreatment of waste tires and polyethylene resin: Rinse the recovered waste tires with water for 3 times, soak them in ethanol solution for 5 minutes, take them out, drain them and dry them at 40°C, and then dry the waste tires one by one Carry out cutting and grinding to obtain waste tire powder, then pass the waste tire powder through a 20-mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com