A kind of detection method of wheat grain hardness

A detection method and technology for wheat grains, which are applied in measurement devices, preparation of samples for testing, and color/spectral property measurement, etc. The effect of rapid screening and detection of large-scale breeding offspring, low equipment purchase cost, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

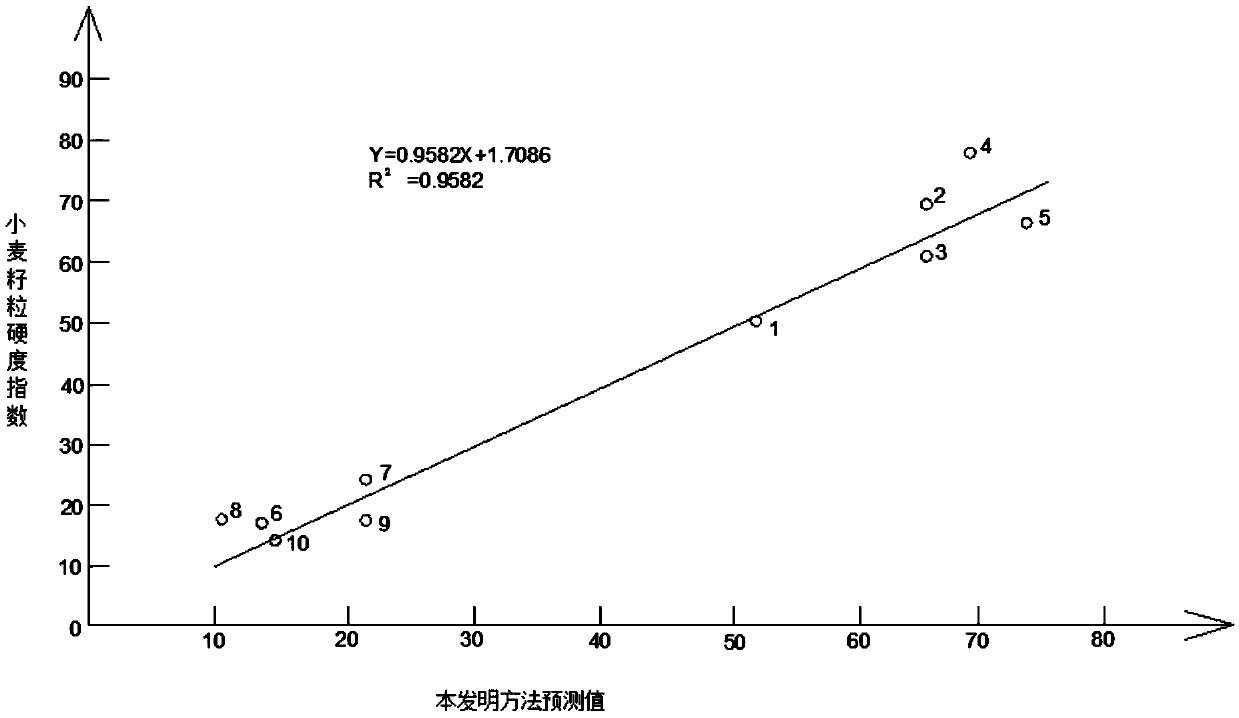

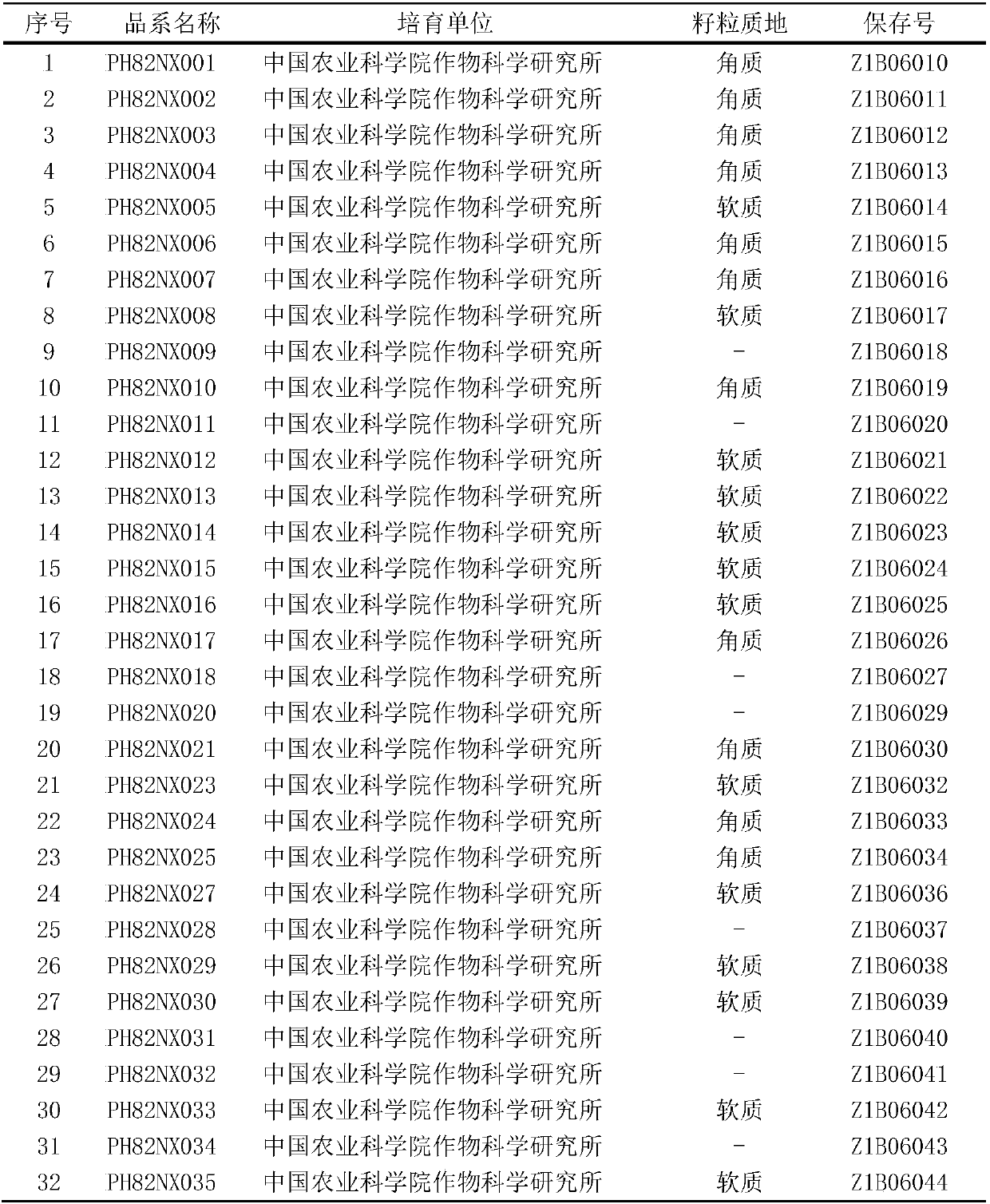

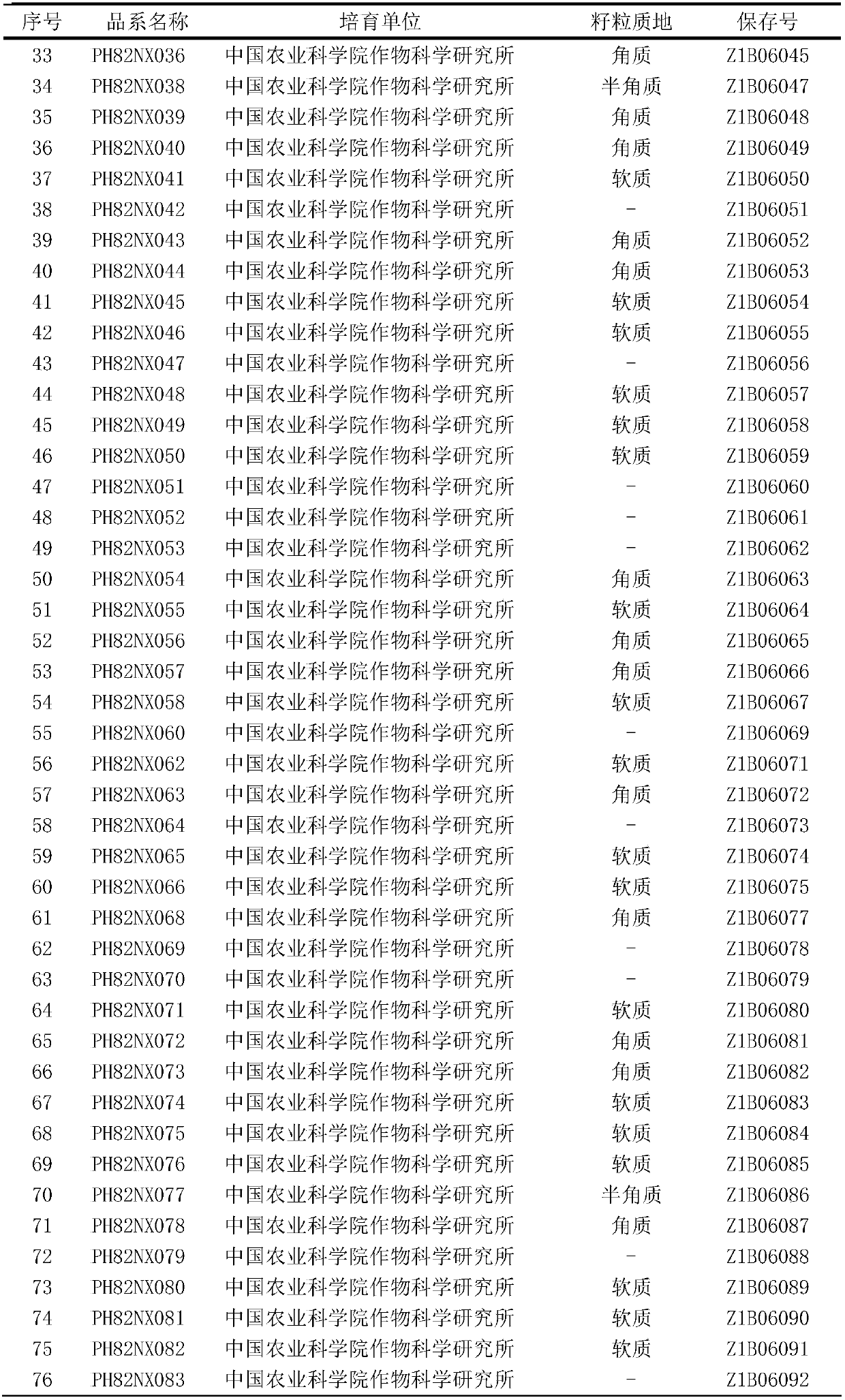

[0022] The invention relates to a method for detecting the hardness of wheat grains, which comprises the steps of moistening wheat and milling flour, collecting the color difference value of the emitted light of the samples in the calibration set, detecting the grain hardness of the samples in the calibration set, establishing a regression calibration model, and collecting the flour reflection of the samples in the prediction set. The light color difference value and the final hardness prediction calculation, the specific operation process is described in detail through specific examples. In the specific examples, the test materials used, unless otherwise specified, were purchased from Shanghai Sangon Bioengineering Technology Co., Ltd., and the used nearly The infrared analyzer was purchased from FOSS Analytical Instrument Company of Denmark, and the Konica Minolta color difference meter CR-400 was purchased from Shanghai Tuxin Electronic Technology Co., Ltd. The Junior small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com