Fine pulverized coal recycling system for pulverized coal pyrolysis and utilization method of fine pulverized coal recycling system

A fine coal powder, pyrolysis technology, applied in the direction of indirect heating dry distillation, direct heating dry distillation, special form of dry distillation, etc., can solve the problem of a large amount of dusty waste gas, etc., achieve low oxygen content, small particle size, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

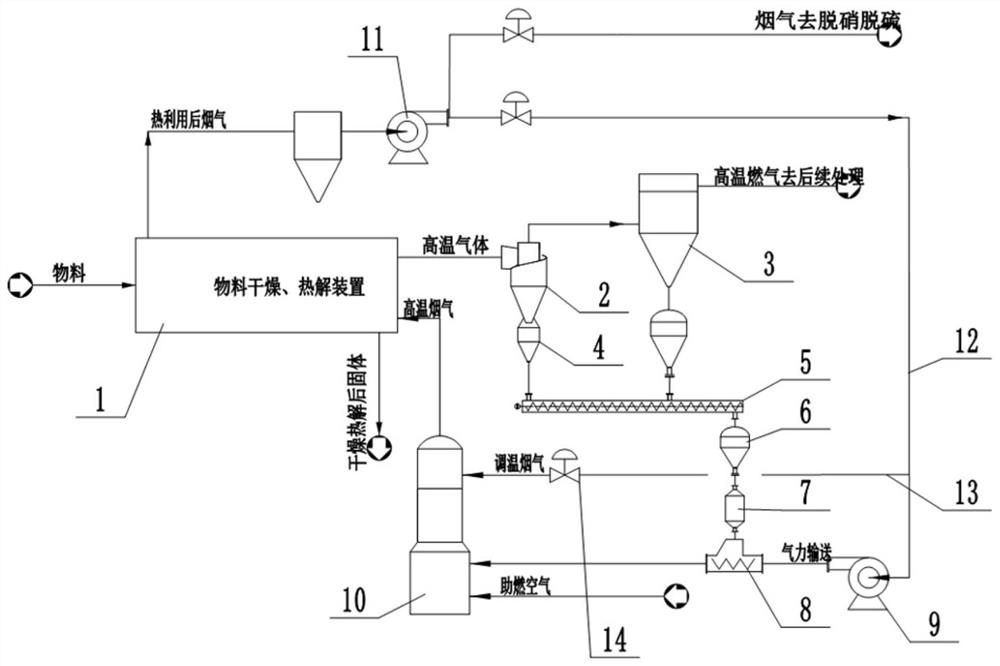

[0024] Such as figure 1 As shown, a system for recovering and reusing fine coal powder contained in raw coal gas from pulverized coal pyrolysis includes a pulverized coal pyrolysis device 1, a high-temperature coarse dust collector 2, a high-temperature fine dust collector 3, a high-temperature coarse dust collector 2 and a high-temperature The bottom outlet of the fine dust collector 3 is equipped with the first fine coal dust collection tank 4 respectively, and the bottom ash outlet of the first fine coal dust collection tank 4 is connected with the screw conveyor 5 respectively, and the discharge of the screw conveyor 5 The second fine coal dust collection tank 6 is installed in the port, and the discharge port of the second fine coal dust collection tank 6 is connected with the coal powder injection device 8 through the cooler 7, and the air inlet of the coal powder injection device 8 is connected with The first flue gas booster 9, the discharge port of the pulverized coal...

Embodiment 2

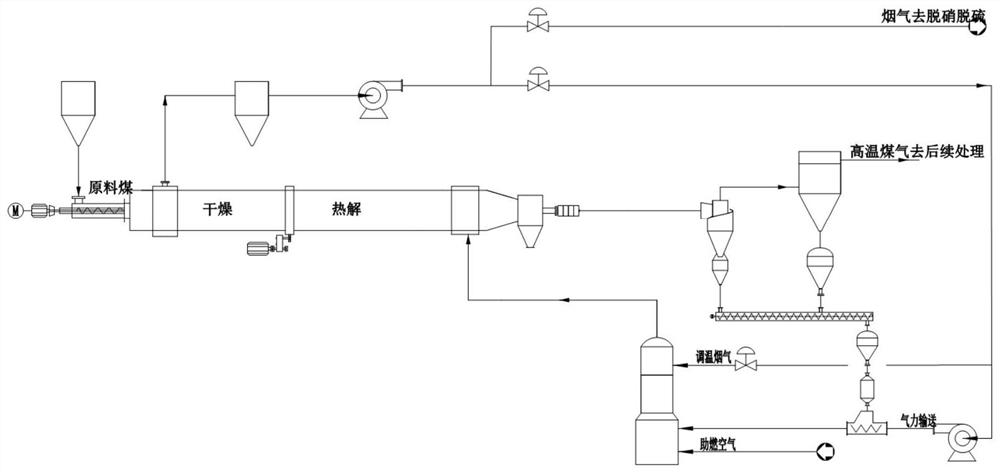

[0027] Such as figure 2 As shown, the pulverized coal pyrolysis device 1 is a pulverized coal pyrolysis rotary kiln, and the flue gas generated by the process heating furnace is mixed with the flue gas from the temperature regulation pipeline and enters the pyrolysis section of the pulverized coal pyrolysis rotary kiln. All the other are the same as the first embodiment.

Embodiment 3

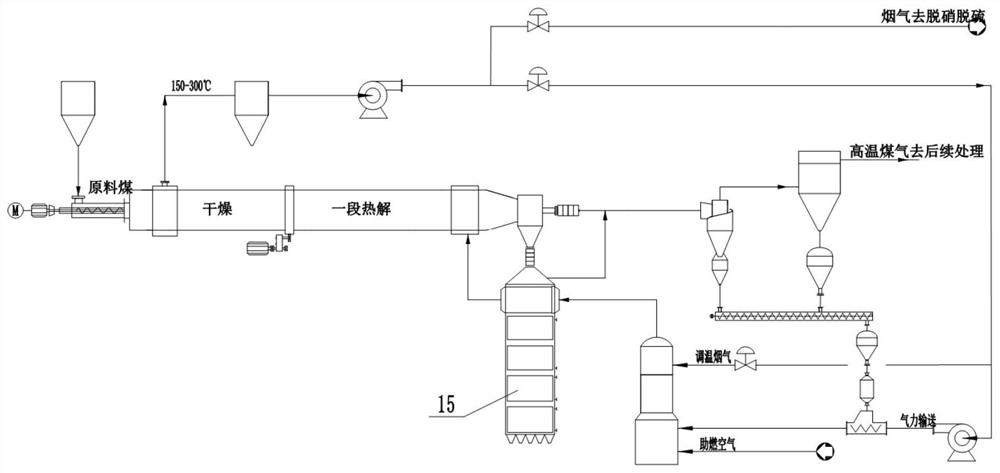

[0029] Such as image 3 As shown, the discharge port of pulverized coal pyrolysis device 1 is also equipped with a heat exchanger 15, and the flue gas produced by the process heating furnace 10 is mixed with the flue gas of the temperature regulation pipeline and enters the heat exchanger 15 to be mixed with the solid Heat exchange of materials, so that the solid materials undergo secondary pyrolysis, the flue gas after heat exchange by the heat exchanger 15 enters the pyrolysis section of the pulverized coal pyrolysis rotary kiln, and the dust-containing waste gas generated by the pyrolysis of solid materials enters the high-temperature The coarse dust collector, then enters the high temperature fine dust collector. All the other are identical with embodiment two.

[0030] In this embodiment, by installing a heat exchanger at the discharge port of the pulverized coal pyrolysis device, the high-temperature flue gas generated by the process heating furnace enters the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com