ZIF-8/TiO2 composite material, preparation method thereof and wastewater treatment method

A technology of ZIF-8 and composite materials, applied in water/sludge/sewage treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of poor pollutant treatment effect and low catalytic efficiency, and the method is simple Easy to control, improve stability, and enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

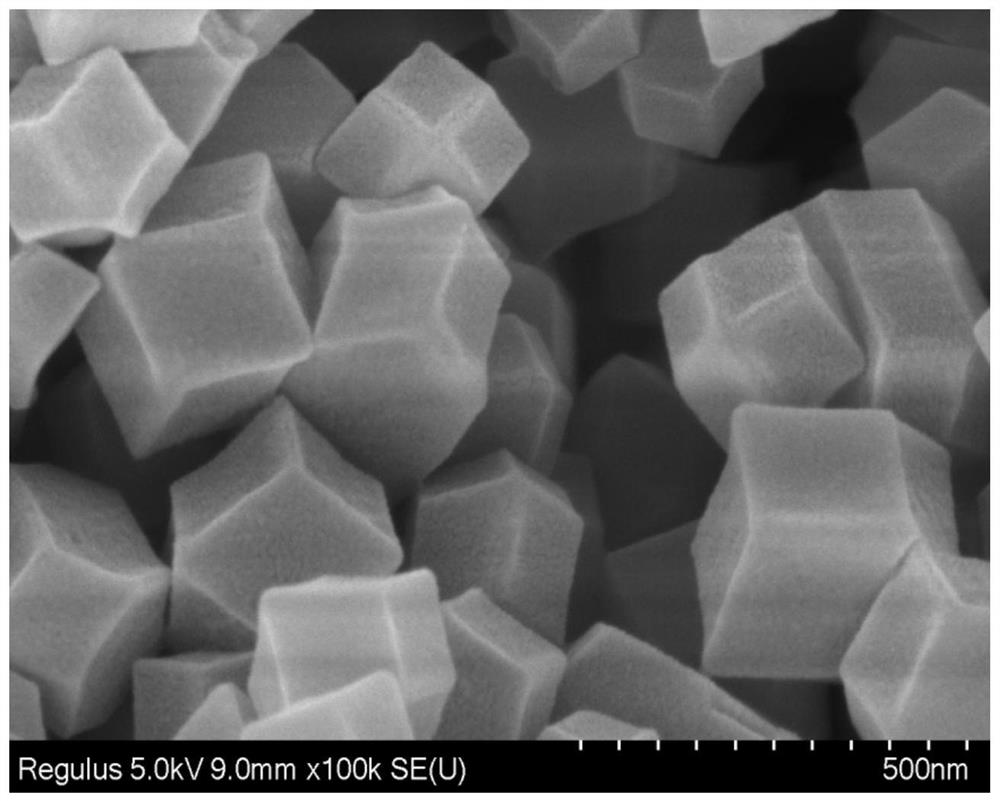

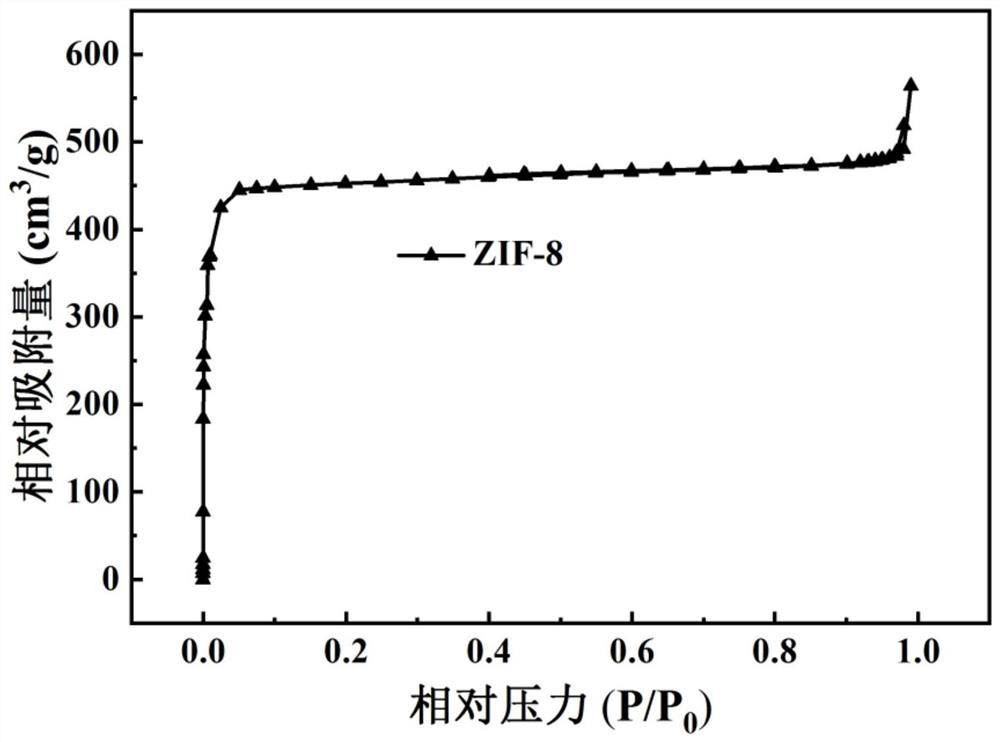

[0038]Weigh 0.44g of zinc acetate dihydrate and add it to a 100mL beaker, dissolve it with 30mL of absolute ethanol, sonicate until it is completely dissolved, weigh 4.1g of 2-methylimidazole and add it to a 100mL beaker, dissolve it with 30mL of absolute ethanol, and sonicate until it is completely dissolved . The two solutions were mixed together and ultrasonicated for 3 hours, then the mixed solution was added into a polytetrafluoroethylene-lined autoclave (100mL), after sealing, the autoclave was continuously heated at 150°C for 6h, and cooled to room temperature After centrifugation, get the precipitate and wash it with absolute ethanol and deionized water, and freeze-dry it for 12 hours to obtain ZIF-8 powder. The scanning electron microscope picture of ZIF-8 powder is as follows: figure 1 As shown, according to figure 2 According to the nitrogen adsorption and desorption test, the BET specific surface area of ZIF-8 powder can reach 1899m 3 / g.

Embodiment 2

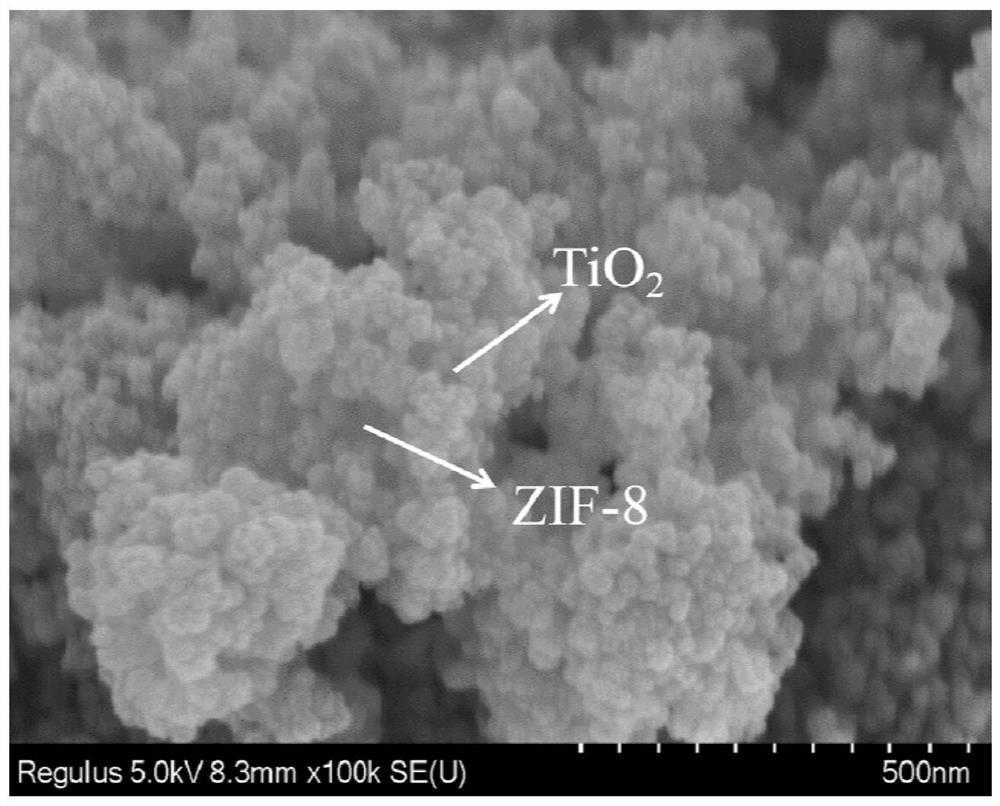

[0040] Weigh 0.5g of the ZIF-8 powder of Example 1 and add it into 60mL of absolute ethanol and stir for 30min to obtain the ZIF-8 precursor solution. Weigh 0.5g of TiO 2 (10-20nm) was added to the ZIF-8 precursor solution and continued to stir for 1h to obtain ZIF-8, TiO 2 mixed solution, and then ZIF-8, TiO 2 The mixture was sonicated for 3 h to form a homogeneous solution. Transfer the homogeneous solution to a polytetrafluoroethylene-lined autoclave (100mL), seal it, and heat the autoclave at 150°C for 12h, cool to room temperature and centrifuge, take the precipitate with absolute ethanol and remove Washed with ion water, freeze-dried for 12h to obtain ZIF-8 / TiO 2 Composite material, named Z150T150, the scanning electron microscope picture of Z150T150 is as follows image 3 shown.

Embodiment 3

[0042] Embodiment 3 will TiO 2 The addition of 0.5g is replaced by 1.0g, all the other preparation steps are the same as embodiment 2, the ZIF-8 / TiO that will make 2 The composite material is named Z100T200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com