Preparation method of phosphorus-nitrogen type ash-free extreme pressure anti-wear agent and extreme pressure anti-wear lubricating oil

An extreme pressure antiwear agent, phosphorus nitrogen type technology, applied in the field of lubricating oil, can solve the problems of insufficient antiwear performance of phosphoramidite ester, complicated post-treatment process, unpleasant smell of additives, etc., and achieve excellent extreme pressure antiwear performance, Good demulsibility, no impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

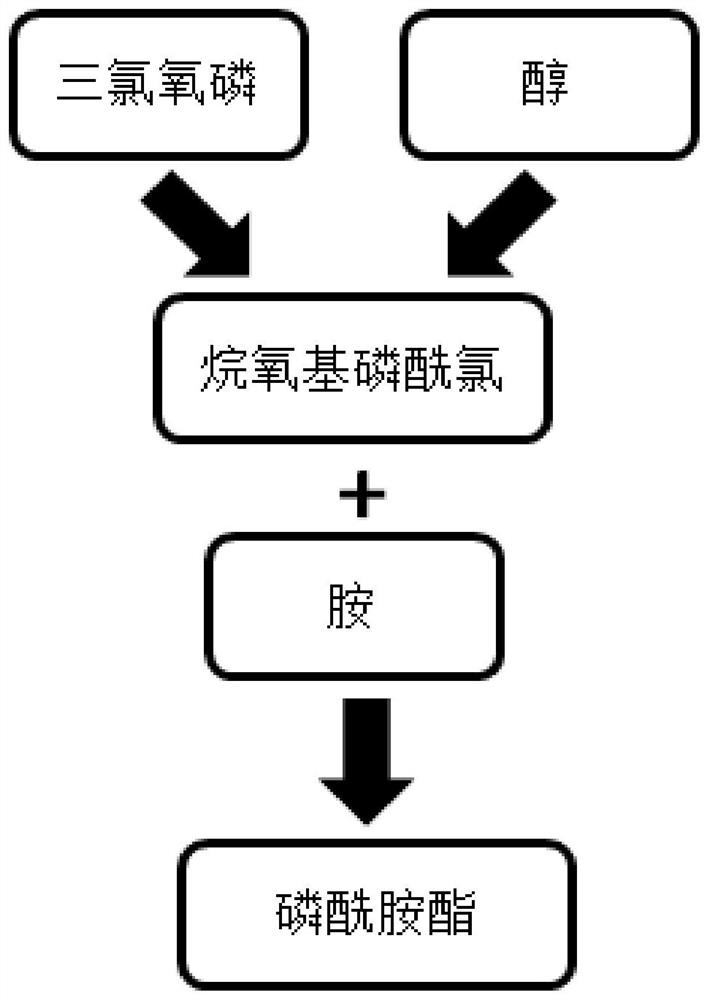

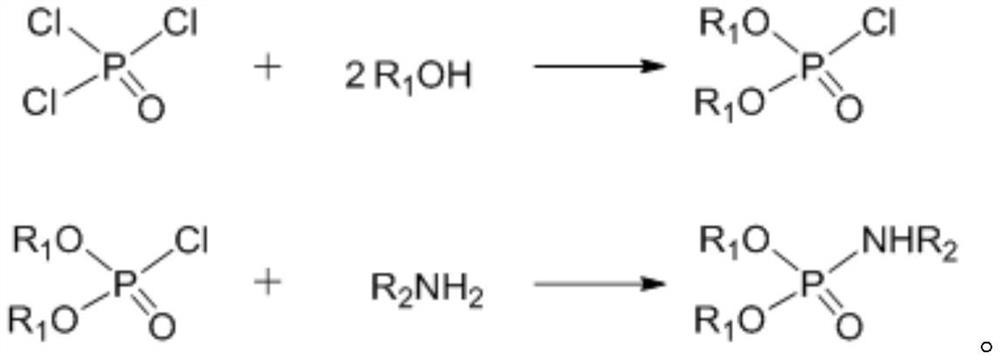

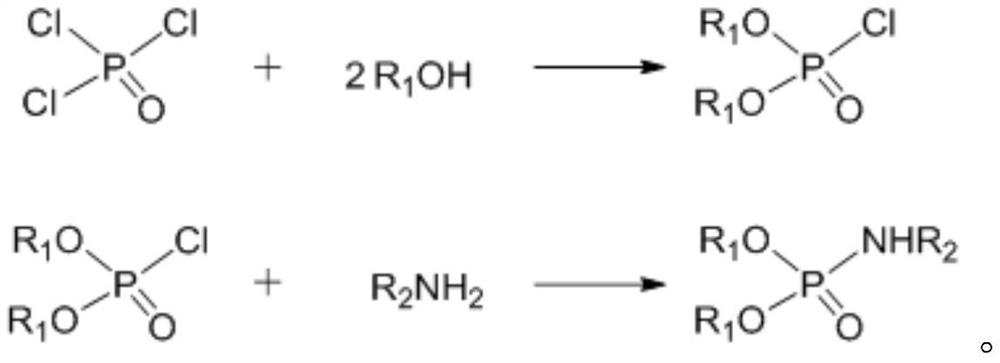

[0030] Such as figure 1 As shown, according to the preparation method of a kind of phosphorus nitrogen type ashless extreme pressure antiwear agent provided by the present invention, comprising:

[0031] Phosphorus oxychloride and alcohol compounds with a molar ratio of 1:1.2 to 1:2.2 are used, and n-hexane is used as a solvent for dilution;

[0032] Add the diluted phosphorus oxychloride and alcohol compounds dropwise into the reaction vessel, and at the same time pass nitrogen gas as a protective gas, and remove the hydrogen chloride gas generated in the reaction in time;

[0033] After the dropwise addition of phosphorus oxychloride and alcohol compounds is completed, the temperature is raised to 30-50°C and kept for 0.5-2 hours to obtain the intermediate alkoxy phosphorus oxychloride;

[0034] Add an organic amine compound with a molar ratio of 0.8:1 to 1.8:1 to phosphorus oxychloride and keep it at a temperature of 50 to 80°C for 1 to 3 hours to obtain phosphoramidite as...

Embodiment 1

[0049] Embodiment 1: First use n-hexane as solvent to dilute 16.5g phosphorus oxychloride and 21g n-hexanol respectively, and simultaneously add it dropwise to a four-necked bottle with nitrogen gas and connected to a tail gas absorption device, drop at room temperature After the addition, raise the temperature to 50°C and keep it warm for about 1.5h to obtain alkoxyphosphoryl chloride; then add 10g of dodecylamine, raise the temperature to 60°C and keep it warm for 1h to get phosphoramidite.

Embodiment 2

[0050] Embodiment two: the n-hexanol among the embodiment one is changed into the n-butanol of equivalence, all the other parts are kept the same with the embodiment one, make light yellow transparent finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com