Ultrafast micro-LED of MIS structure based on local surface plasmon coupling enhancement and production method of ultrafast micro-LED

A technology of localized surface plasmon and MIS structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of low modulation bandwidth, and achieve the effects of increasing modulation bandwidth, simple preparation process, and improving recombination rate and recombination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing an ultrafast micro-LED based on a localized surface plasmon coupling enhanced MIS structure as described above, which includes the following steps:

[0054] S100. Using metal-organic vapor phase epitaxy technology to grow a low-temperature buffer layer on the substrate, and then raise the temperature to grow a high-temperature gallium nitride layer on the buffer layer;

[0055] S200, continue to use metal-organic vapor phase epitaxy technology to grow a p-type active layer on the gallium nitride layer;

[0056] S300. Depositing an insulating layer on the p-type active layer by using plasma-enhanced chemical vapor deposition technology;

[0057] S400, using a chemical wet etching process to transfer the current spreading layer, and growing the current spreading layer on the surface of the insulating layer;

[0058] S500. Evaporating a metal thin film layer on the surface of the current spreading layer by using t...

Embodiment 1

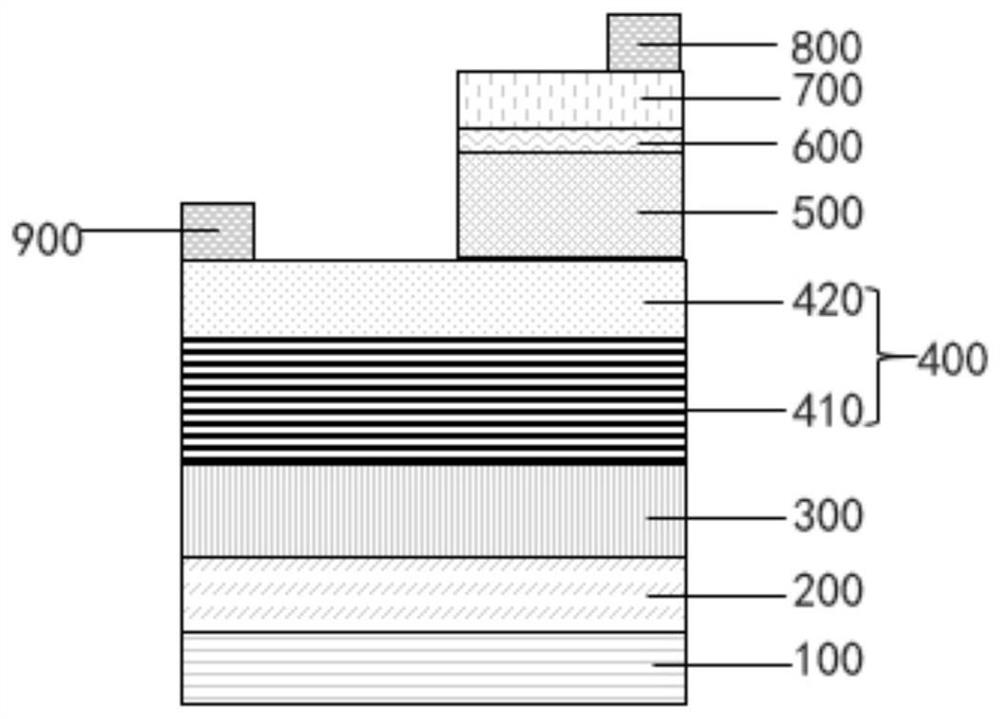

[0065] The present invention provides as Figure 1-2 The specific structure of the ultrafast micro-LED based on the localized surface plasmon coupling enhanced MIS structure shown in Example 1, and its preparation method is as follows:

[0066] Among them, in the preparation process, trimethylaluminum (TMAl) and trimethylgallium (TMGa) were used as group III sources, ammonia (NH3) was used as group V sources, and dipentyl magnesium (Cp2Mg) was used as p-type active layer doping agent, high-purity hydrogen as the carrier gas.

[0067] 1) growing the buffer layer 200 and the gallium nitride layer 300, specifically:

[0068] 1.1) Using metal organic vapor phase epitaxy technology, before growing epitaxy, place sapphire substrate 100 in H 2 In the atmosphere, remove the contamination on the surface at a high temperature of 1100°C and a reaction chamber pressure of 100Torr; after lowering the temperature to 800°C, feed TMGa and NH under a reaction chamber pressure of 500Torr 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com