Flame-retardant epoxy resin as well as preparation method and application thereof

A technology of epoxy resin and resin, which is applied in the field of flame retardant epoxy resin and its preparation, can solve the problems of low flame retardant efficiency, agglomeration of flame retardant particles, and decreased stability of flame retardant effect, and achieve high flame retardant performance, The effect of high physical and mechanical properties and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a preparation method of flame retardant epoxy resin, the steps are as follows:

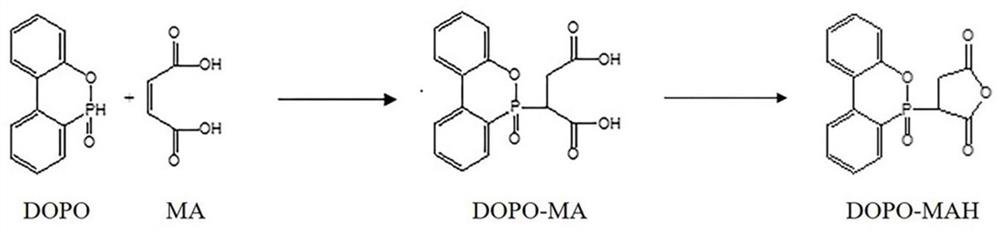

[0065] (1) Synthesis of phosphorus-containing flame retardant curing agent DOPO-MAH:

[0066] 200ml of xylene was placed in a three-necked flask as a solvent, and 60g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) was dissolved in it, and then divided into batches within 30min Add 27.2g of maleic acid (MA), react at a temperature of 125°C for 6h, then cool down to 80°C, add 150ml of tetrahydrofuran into the system, react for 2h, then filter with suction, wash with THF for 3 times, and then filter with suction , to obtain DOPO-maleic acid (DOPO-MA).

[0067] Pour the obtained DOPO-MA and 82ml of acetic anhydride into a three-necked flask, then react in a constant temperature water bath at 130°C for 4.5h, filter with suction, wash twice with acetic anhydride, and filter with suction again to obtain DOPO-maleic acid Anhydride (DOPO-MAH) phosphorus-conta...

Embodiment 2

[0079] This embodiment provides a preparation method of flame retardant epoxy resin, the steps are as follows:

[0080] (1) Synthesis of phosphorus-containing flame retardant curing agent:

[0081] 250ml of xylene was placed in a three-necked flask as a solvent, and 80g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) was dissolved in it, and then added in batches within 40min 35.4g maleic acid (MA), the two reacted at 130°C for 6.5h, then cooled to 85°C, added 200ml tetrahydrofuran into the system, reacted for 2.5h, filtered with suction, washed twice with tetrahydrofuran, and pumped again Filter to obtain DOPO-maleic acid (DOPO-MA).

[0082] Pour the obtained DOPO-MA and 110ml of acetic anhydride into a three-necked flask, then react in a constant temperature water bath at 130°C for 5 hours, filter with suction, wash with acetic anhydride twice, and filter with suction again to obtain DOPO-maleic anhydride (DOPO-MAH) Phosphorous curing agent.

[0083] (2) Synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com