Low-temperature denitration catalyst capable of resisting halogen element Cl poisoning and preparation method and application of low-temperature denitration catalyst

A low-temperature denitrification and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of long preparation cycle, abnormal discharge of target pollutants, limited application range, etc., and achieve good results Effects of anti-halogen Cl poisoning performance, good NOx elimination ability, and high NOx elimination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Mn-Ce-O by Surface Impregnation Combustion Method x / TiO 2 catalyst

[0038] (1) Weigh 2.87g of manganese nitrate (50% aqueous solution), 1.09g of cerium nitrate and 3.80g of glycine and dissolve them in 7mL of deionized water, stir and mix evenly;

[0039] (2) Weigh 2g of anatase titanium dioxide with a particle size of 100nm and add it to the mixed solution, and stir it with a magnetic force for 1h;

[0040] (3) Place the product obtained in step (2) in a muffle furnace preheated to 300°C and burn rapidly for 1-2 minutes, then continue to heat up from 300°C to 450°C, roast at 450°C for 4 hours, and finally grind Prepared Mn-Ce-O x / TiO 2 Catalyst, denoted as MCT-G.

Embodiment 2

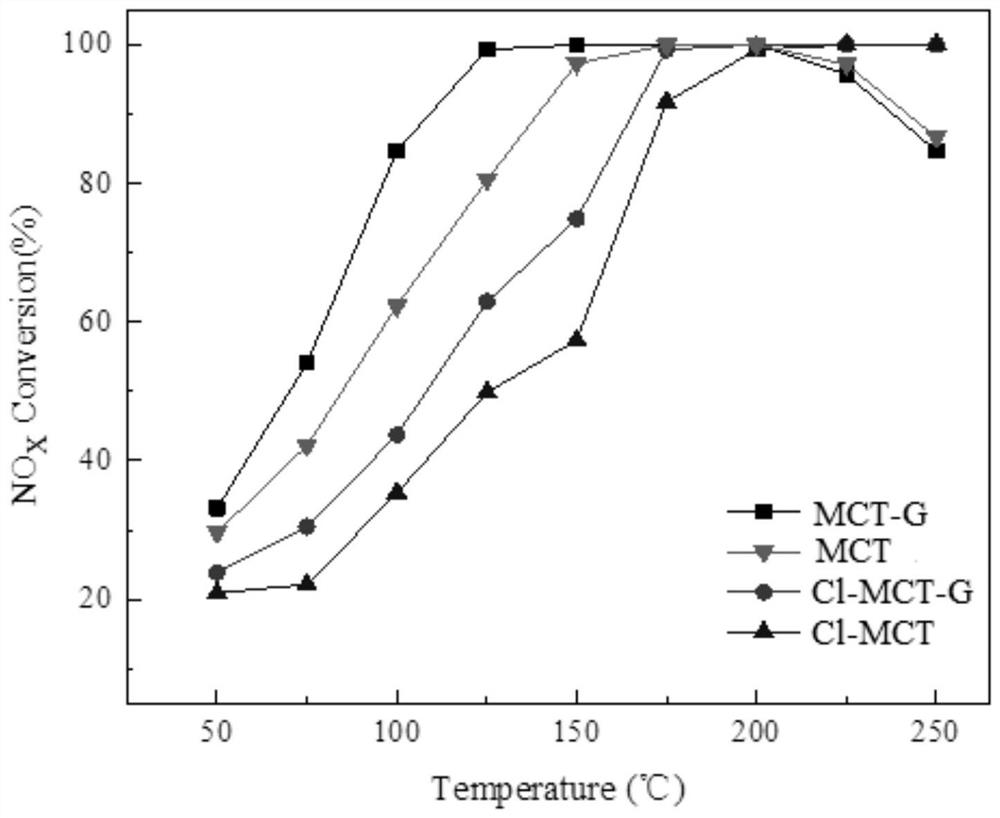

[0057] MCT, MCT-G, Cl-MCT, Cl-MCT-G catalysts for NH 3 -Evaluation of catalytic activity of SCR low temperature denitrification reaction

[0058] The reaction conditions and process of activity test are as follows:

[0059] 500ppm NO, 500ppm NH 3 , 5vol%O 2 , N 2 As carrier gas, all gases are provided by cylinder gas, the total gas flow rate is 200mL / min, and the space velocity (GHSV) is 80000mL / (g·h). During the reaction, ensure that the quartz reaction tube of the catalyst is located in the constant temperature area of the reactor. The activity test temperature is 50-250°C, and the activity test is carried out at every interval of 25°C as a temperature point. The test results are as follows: figure 1 shown.

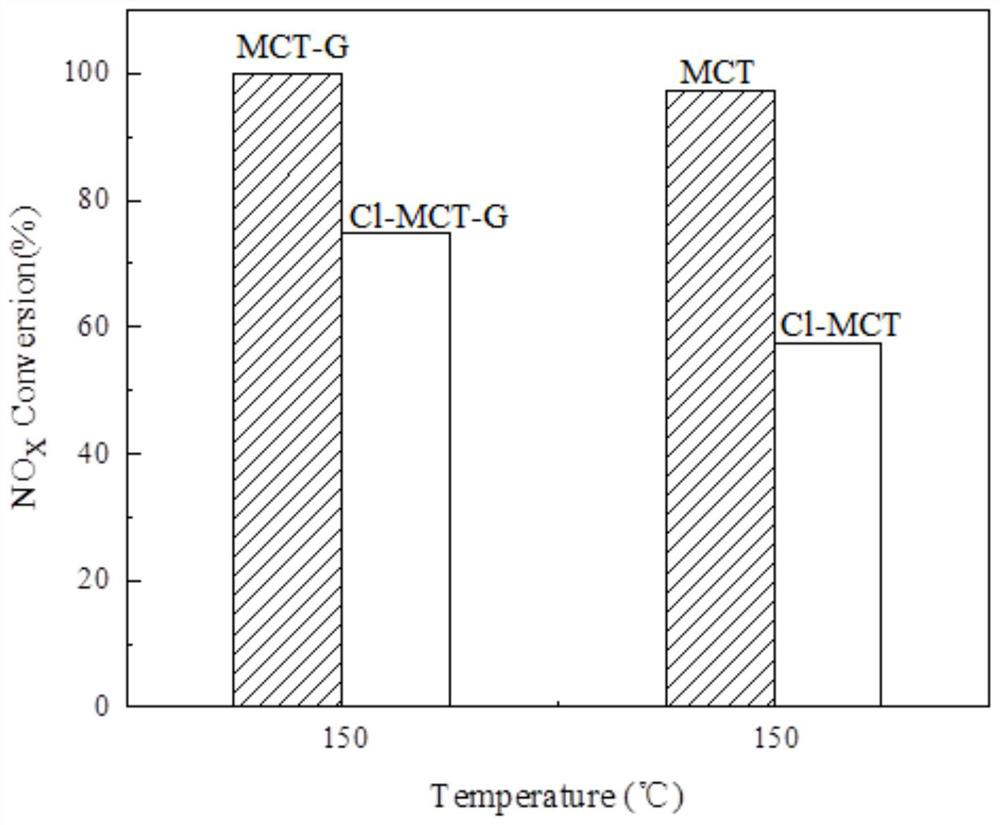

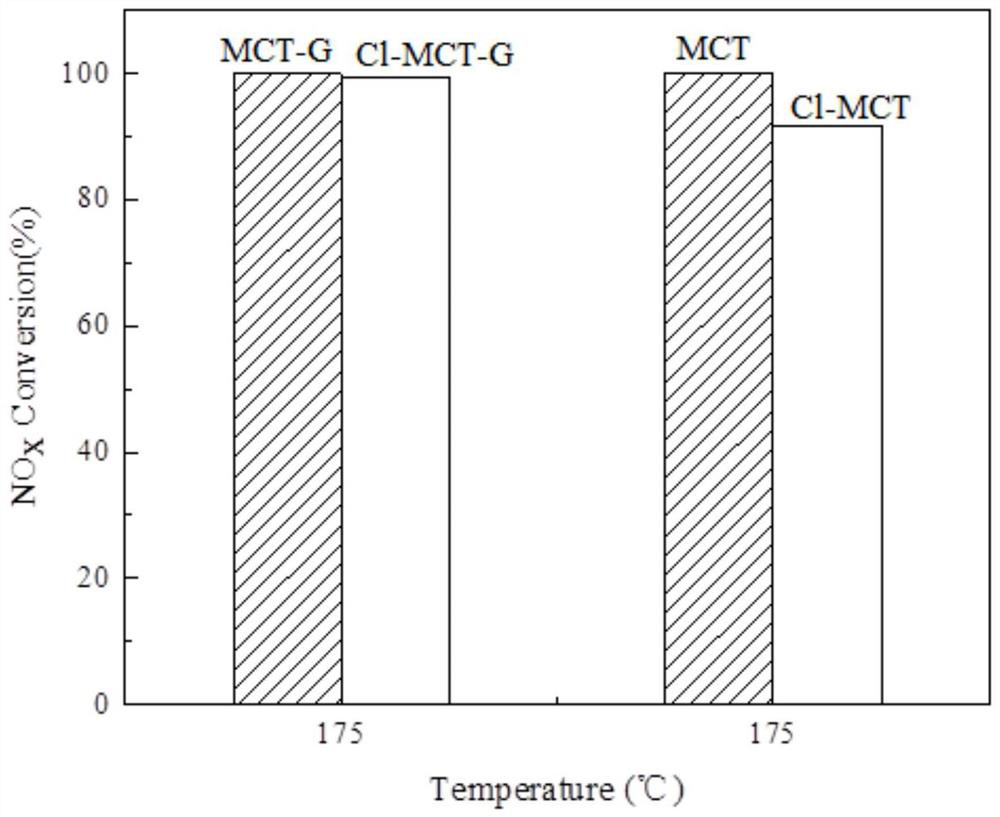

[0060] from figure 1 It can be seen that the prepared Mn-Ce-O x / TiO 2 Catalyst NO x The order of conversion rate is as follows: MCT-G>MCT>Cl-MCT-G>Cl-MCT. At low temperature ( figure 2 As shown, after MCT-G catalyst was poisoned by Cl, NO x The conversion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com