A modified low-temperature SCO denitration catalyst and its preparation method

A denitrification catalyst and low-temperature technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor stability of MOFs materials, achieve cheap raw materials, promote catalytic oxidation reactions, and easily obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

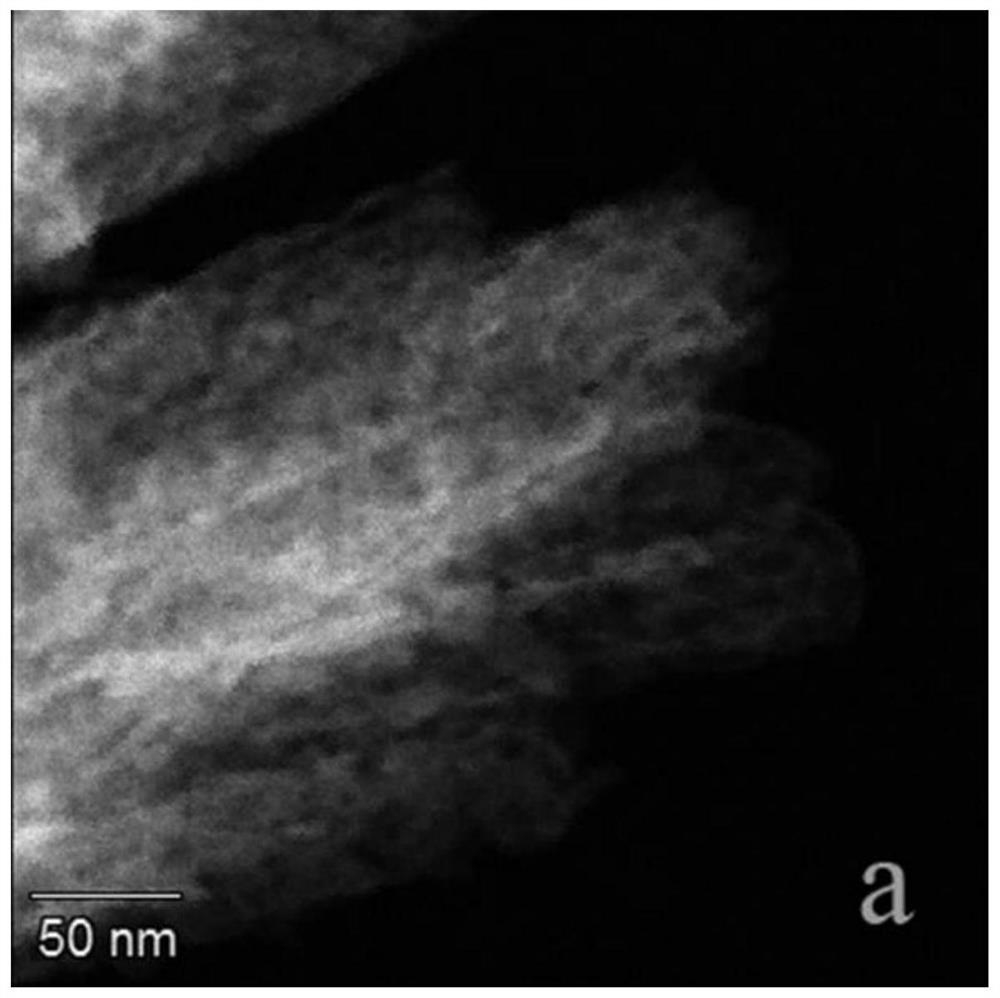

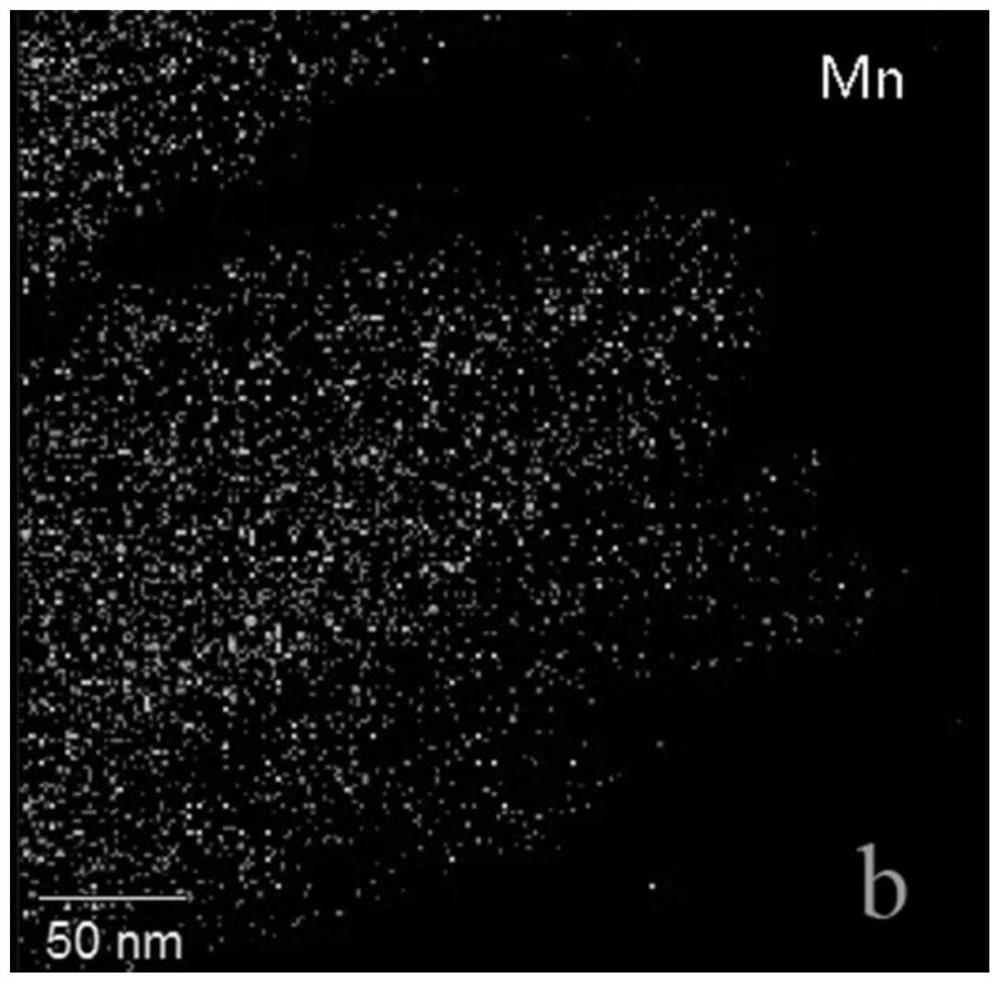

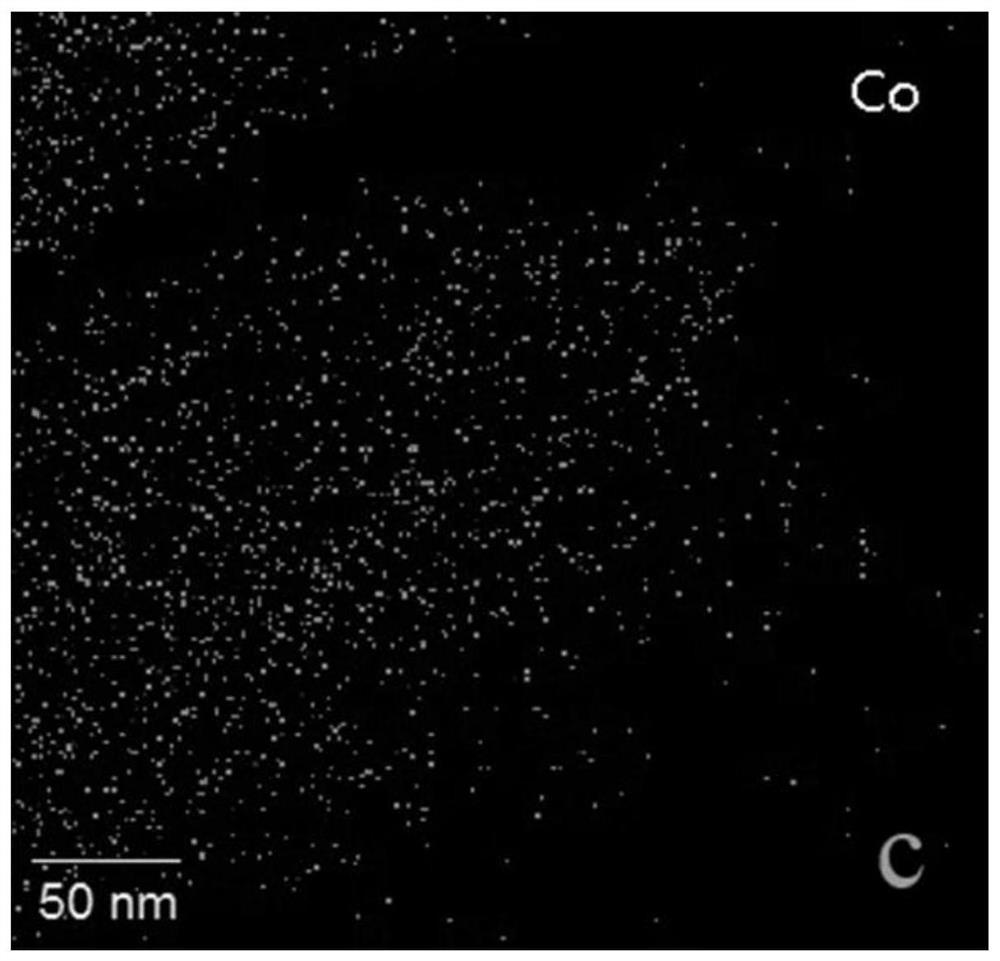

Image

Examples

Embodiment 1

[0041] The preparation of low-temperature SCO denitration catalyst comprises the following steps:

[0042] (1) Mn(NO 3 ) 2 4H 2O(0.852g, 3.4mol), Co(NO 3 ) 2 ·6H 2 O (1.0g, 3.4mol) and Ce (NO 3 ) 2 ·6H 2 O (0.037g, 0.085mol) (the molar ratio of manganese and cobalt is 1:1, and the molar ratio of manganese and cerium is 1:0.025) is added in the DMF of 50mL, adds isonicotinic acid (0.384g, 3.1mol), Ultrasound for 20 minutes to fully mix the solution to obtain a mixed solution;

[0043] (2) Put the mixed solution in a 90°C drying oven and react for 20 hours. After the solution is cooled, remove the supernatant, wash with fresh DMF and ether three times, filter, and place the filtered solid material in a vacuum at 50°C. Dry in a drying box for 24 hours;

[0044] (3) The dried solid material was put into a muffle furnace and roasted at 300° C. for 2 h to prepare a low-temperature SCO denitration catalyst (referred to as Mn-CAT).

Embodiment 2

[0046] The preparation of the modified low-temperature SCO denitration catalyst comprises the following steps:

[0047] (1) Mn(NO 3 ) 2 4H 2 O(0.852g, 3.4mol), Co(NO 3 ) 2 ·6H 2 O (2g, 6.8mol) and Ce (NO 3 ) 2 ·6H 2 O (0.037g, 0.085mol) (the molar ratio of manganese and cobalt is 1:2, and the molar ratio of manganese and cerium is 1:0.025) is added in the DMF of 50mL, adds isonicotinic acid (0.192g, 1.56mol), Ultrasound for 30 minutes to fully mix the solution to obtain a mixed solution;

[0048] (2) Put the mixed solution in a 100°C drying oven and react for 24 hours. After the solution is cooled, remove the supernatant, wash with fresh DMF and ether for 4 times, filter, and place the filtered solid material in a vacuum at 60°C. Dry in a drying box for 20 hours;

[0049] (3) Put the dried solid material into a muffle furnace and roast at 350° C. for 2.5 hours to prepare a low-temperature SCO denitration catalyst (referred to as Mn-CAT).

[0050] (4) Put the prepare...

Embodiment 3

[0052] The preparation of the modified low-temperature SCO denitration catalyst comprises the following steps:

[0053] (1) Mn(NO 3 ) 2 4H 2 O(0.852g, 3.4mol), Co(NO 3 ) 2 ·6H 2 O (0.5g, 1.7mol) and Ce (NO 3 ) 2 ·6H 2 O (0.015g, 0.034mol) (the molar ratio of manganese and cobalt is 1:0.5, and the molar ratio of manganese and cerium is 1:0.01) is added in 50mL of DMF, isonicotinic acid (0.768g, 6.2mol) is added, Ultrasound for 40 minutes to fully mix the solution to obtain a mixed solution;

[0054] (2) Put the mixed solution in a 110°C drying oven and react for 30 hours. After the solution is cooled, remove the supernatant, wash with fresh DMF and ether for 5 times, filter, and place the filtered solid material in a vacuum at 75°C. Dry in a drying box for 22 hours;

[0055] (3) The dried solid material was put into a muffle furnace and roasted at 400° C. for 3 h to prepare a low-temperature SCO denitration catalyst (referred to as Mn-CAT).

[0056] (4) Put the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com