Preparation method of samarium-cobalt permanent magnet suitable for high-temperature and high-pressure pure hydrogen environment

A high temperature and high pressure, samarium cobalt magnet technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of unusable materials, failure of samarium cobalt permanent magnet materials, etc., to increase the density and improve the intergranular Continuity, the effect of hindering the entry of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

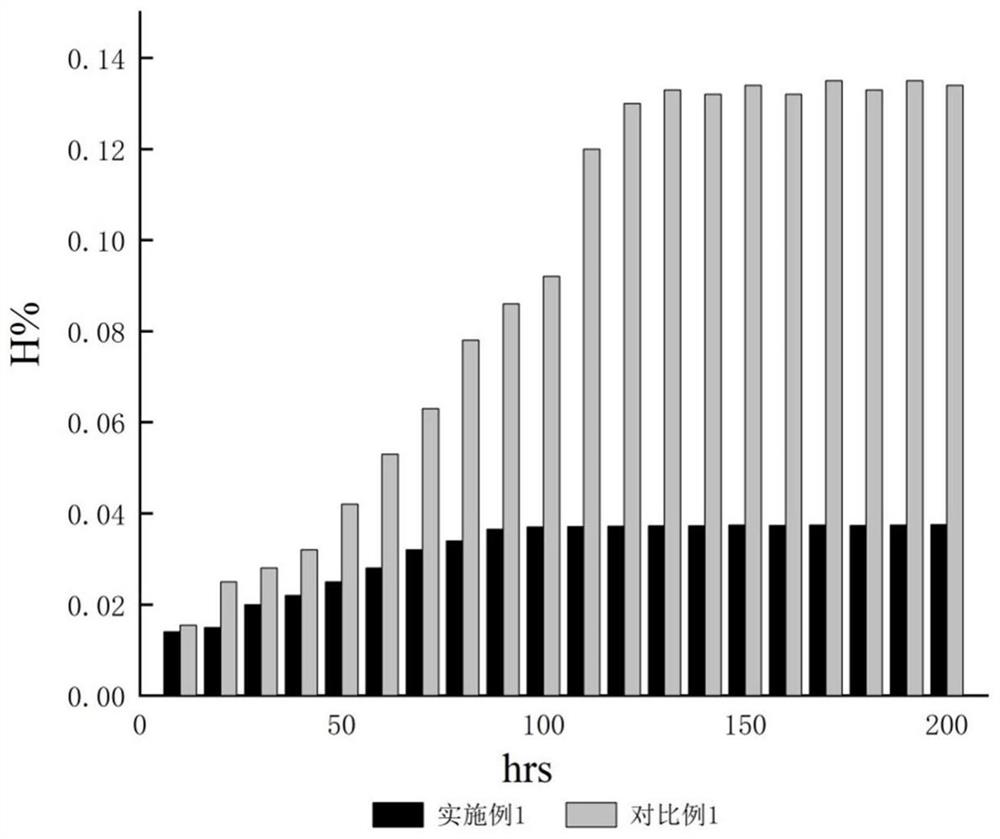

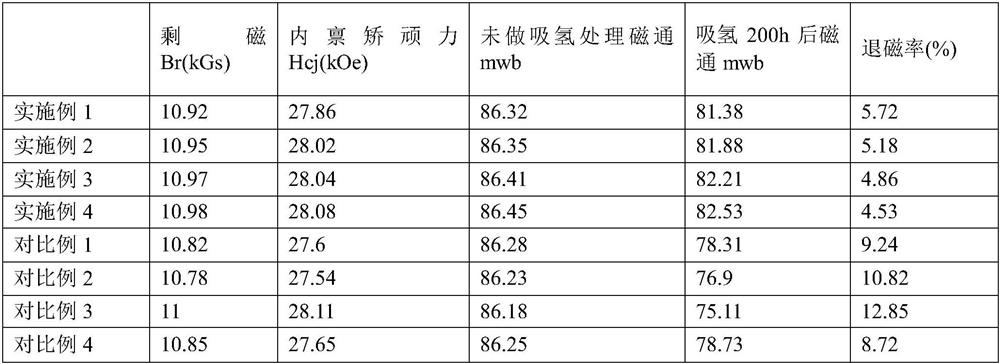

Examples

preparation example Construction

[0036] A samarium cobalt permanent magnet suitable for high temperature and high pressure pure hydrogen environment, its expression (excluding the coating) is: Sm(Co 1-x-y-v Fe x Cu y Zr v ) z, wherein x=0.18~0.26, y=0.14~0.2, v=0.01~0.03, z=7.0~7.5; z is the atomic ratio of transition group elements Co, Fe, Cu, Zr and rare earth element Sm, and its preparation method includes The following steps:

[0037] (1) According to the ratio of each element, the raw materials are melted in an inert environment to obtain alloy ingots or slabs.

[0038] (2) Crushing the obtained ingot or cast sheet under a nitrogen environment, and then jet milling under an inert environment to obtain samarium cobalt powder.

[0039] (3) The obtained samarium-cobalt powder is oriented and formed in an inert environment and a 1-5T magnetic field, and then cold isostatically pressed at 180-230MPa to obtain a samarium-cobalt magnet green body with a particle size of 3.8-4.5 μm.

[0040] (4) Sinter the...

Embodiment 1

[0043] A samarium cobalt permanent magnet suitable for high temperature and high pressure pure hydrogen environment, its expression (excluding the coating) is Sm(Co 0.65 Fe 0.18 Cu 0.15 Zr 0.02 ) 7.1 , the specific preparation steps are as follows:

[0044] (1) Put the samarium-cobalt magnet raw material into the vacuum melting induction furnace after batching according to the element ratio, and obtain the alloy ingot by melting in an inert environment;

[0045] (2) Pass the ingot obtained by smelting into nitrogen for crushing treatment, and then produce samarium cobalt powder with an average particle size of 4.1 μm through jet milling under an inert environment;

[0046] (3) Orientate the samarium-cobalt powder under the protection of argon gas and in a magnetic field (the magnetic field strength is 2T), and then perform cold isostatic pressing for 30 minutes (the pressure for cold isostatic pressing is 200MPa) to obtain a samarium-cobalt magnet green body;

[0047] (4...

Embodiment 2

[0051] A samarium cobalt permanent magnet suitable for high temperature and high pressure pure hydrogen environment, its expression (excluding the coating) is Sm(Co 0.61 Fe 0.2 Cu 0.16 Zr 0.03 ) 7.2 , the specific preparation steps are as follows:

[0052] (1) Put the samarium-cobalt magnet raw material into the vacuum melting induction furnace after batching according to the element ratio, and obtain the alloy ingot by melting in an inert environment;

[0053] (2) Pass the ingot obtained by smelting into nitrogen for crushing treatment, and then produce samarium cobalt powder with an average particle size of 4.1 μm through jet milling under an inert environment;

[0054] (3) Orientate the samarium-cobalt powder under the protection of argon gas and in a magnetic field (the magnetic field strength is 2T), and then perform cold isostatic pressing for 30 minutes (the pressure for cold isostatic pressing is 200MPa) to obtain a samarium-cobalt magnet green body;

[0055] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com