Iron-based soft magnetic composite material and preparation method thereof

A soft magnetic composite material, iron-based technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of reducing the magnetic permeability of stator magnets, environmental pollution of insulating paint, and increasing process flow, etc. The effect of improving magnet resistivity, protecting the environment, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

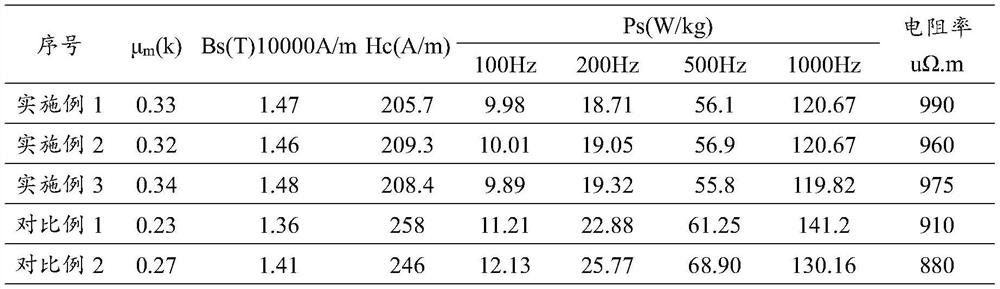

Embodiment 1

[0038] A method for preparing an iron-based soft magnetic composite material, comprising:

[0039] 1. Take water and atomize iron powder (purity>99.0%, particle size 75-200μm, apparent density 3.0g / cm 3 ) to perform mechanical ball milling pretreatment, the ball-to-material ratio is 5:1, the ball mill rotating speed is 450 rpm, and the pretreatment time is 8 minutes;

[0040] 2. Mix the orthophosphoric acid-ethanol solution with a volume ratio of 1:60 and the pretreated iron powder, dry at 60°C for 60 minutes, and sieve; mix the 1:20 epoxy resin-ethanol solution with phosphoric acid-coated iron powder evenly Mix, dry again at 60°C for 60 minutes, and then sieve to obtain inorganic-organic composite coating powder;

[0041] 3. Add 0.5wt% zinc stearate lubricant to the powder and mix evenly; use 1000MPa pressure to press and form;

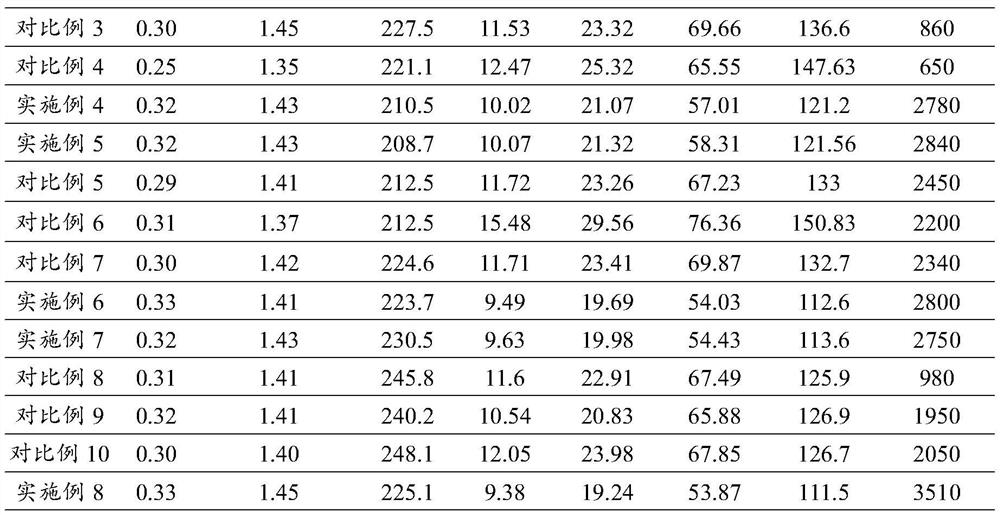

[0042] 4. Place the pressed sample in an annealing furnace and vacuumize to 10 -3 Pa filled with nitrogen to stabilize to 0.04MPa, start heating,...

Embodiment 2

[0045] A method for preparing an iron-based soft magnetic composite material, comprising:

[0046] 1. Take water and atomize iron powder (purity>99.0%, particle size 75-200μm, apparent density 3.0g / cm 3 ) to perform mechanical ball milling pretreatment, the ball-to-material ratio is 3:1, the ball mill rotating speed is 500 rpm, and the pretreatment time is 5 minutes;

[0047] 2. Mix 1:80 orthophosphoric acid-ethanol solution with pretreated iron powder, dry at 80°C for 40 minutes, and sieve; mix 1:15 epoxy resin-ethanol solution with phosphoric acid-coated iron powder evenly, Dry again at 50°C for 60 minutes and sieve to obtain inorganic-organic composite coating powder;

[0048] 3. Add 0.5wt% zinc stearate lubricant to the powder and mix evenly; use 900MPa pressure to press and form;

[0049] 4. Place the pressed sample in an annealing furnace and vacuumize to 10 -3 Pa filled with nitrogen to stabilize to 0.04MPa, start heating, from room temperature to 260 ° C, the heatin...

Embodiment 3

[0051] A method for preparing an iron-based soft magnetic composite material, comprising:

[0052] 1. Take reduced iron powder (purity>99.0%, particle size is 75-200μm, apparent density is 4.5g / cm 3 ) to perform mechanical ball milling pretreatment, the ball-to-material ratio is 6:1, the ball mill rotating speed is 300 rpm, and the pretreatment time is 10 minutes;

[0053] 2. Mix 1:70 orthophosphoric acid-ethanol solution with pretreated iron powder, dry at 50°C for 60 minutes, and sieve; mix 1:30 epoxy resin-ethanol solution with phosphoric acid-coated iron powder evenly, Dry again at 80°C for 40 minutes and sieve to obtain inorganic-organic composite coating powder;

[0054] 3. Add 0.7wt% zinc stearate lubricant to the powder and mix evenly; use 800MPa pressure to press and form;

[0055] 4. Place the pressed sample in an annealing furnace and vacuumize to 10 -3 Pa filled with nitrogen to stabilize to 0.02MPa, start heating, from room temperature to 270°C, the heating rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com