Metal-doped cryptomelane molecular-sieve catalyst as well as preparation method and application thereof

A metal-doped, manganese-potassium ore technology, applied in molecular sieve catalysts, catalyst activation/preparation, separation methods, etc., can solve the problems of ammonia escape, high carbon monoxide concentration in exhaust smoke, etc., and achieve improved removal rate, excellent resistance to sulfur and water Performance, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

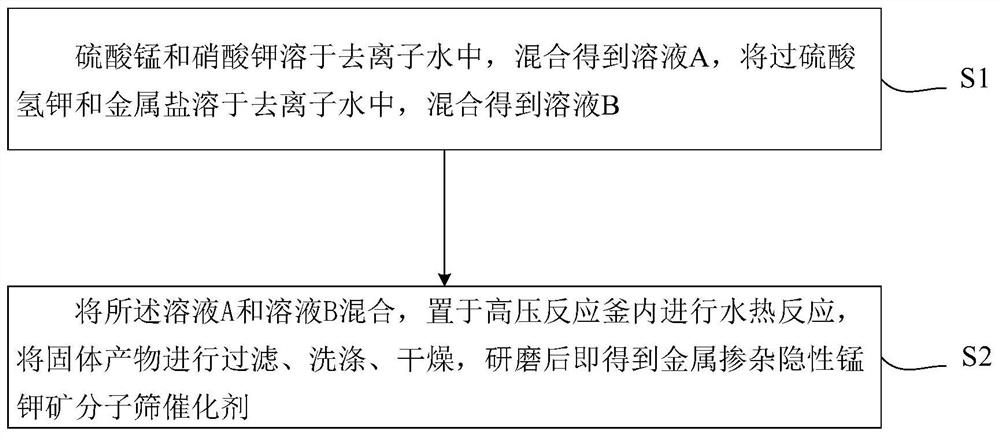

[0029] combine figure 1 Shown, a kind of preparation method of metal-doped recessive manganese potassium ore molecular sieve catalyst comprises the steps:

[0030] S1, manganese sulfate MnSO 4 ·H 2 O and potassium nitrate KNO 3 Dissolve in deionized water, mix to obtain solution A, dissolve potassium hydrogen persulfate and metal salt in deionized water, and mix to obtain solution B;

[0031] S2. Mix solution A and solution B, and place them in a high-pressure reactor for hydrothermal reaction, filter, wash, dry the solid product, and obtain the metal-doped latent manganese-potassium ore molecular sieve catalyst after grinding.

[0032] It can be understood that cryptopotassium manganese oxide molecular sieve is a new type of material similar to zeolite molecular sieve structure, which has the advantages of large specific surface area, low isoelectric point, strong oxidation ability, and high cation exchange capacity. The pore structure makes it exhibit excellent conductiv...

Embodiment 1

[0050] This embodiment provides a method for preparing a metal-doped recessive manganite molecular sieve catalyst, comprising the following steps:

[0051] 1) Add 0.69gMnSO 4 ·H 2 O and 0.83g KNO 3 Dissolve in 25mL of deionized water, mix with 7.5g of potassium persulfate and 0.356g of cobalt nitrate dissolved in 50mL of deionized water, and stir vigorously;

[0052] 2) Transfer the mixed solution prepared in step 1) to a 100mL polytetrafluoroethylene-lined reactor and seal it at 120°C for 24 hours, then filter the solid product obtained by the reaction, wash it with water, dry it, and then grind it into a powder. A recessive manganite molecular sieve catalyst with a Co doping amount of 0.3 was obtained.

[0053] The recessive manganese ore molecular sieve catalyst with a Co doping amount of 0.3 prepared in Example 1 has a reaction temperature of 150°C and a space velocity of 5000h -1 , CO and NO were respectively under 1000ppm to carry out the out-of-stock reaction.

[0...

Embodiment 2

[0056] This embodiment provides a method for preparing a metal-doped recessive manganite molecular sieve catalyst, comprising the following steps:

[0057] 1) Add 0.69gMnSO 4 ·H 2 O and 0.83g KNO 3 Dissolved in 25mL of deionized water, mixed with 7.5g of potassium persulfate and 0.475g of cobalt nitrate dissolved in 50mL of deionized water, and stirred vigorously;

[0058] 2) Transfer the mixed solution prepared in step 1) to a 100mL polytetrafluoroethylene-lined reactor and seal it at 120°C for 24 hours, then filter the solid product obtained by the reaction, wash it with water, dry it, and then grind it into a powder. A recessive manganite molecular sieve catalyst with a Co doping amount of 0.4 was obtained.

[0059] The recessive manganese ore molecular sieve catalyst with a Co doping amount of 0.4 prepared in Example 2 has a reaction temperature of 150°C and a space velocity of 5000h -1 , CO and NO were respectively under 1000ppm to carry out the out-of-stock reaction....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com