Resource utilization method of 2, 4-dichloroacetophenone wastewater

A technology for dichloroacetophenone and resource utilization, which is applied in chemical instruments and methods, separation/purification of aluminum chloride and carbonyl compounds, etc. And other problems, to achieve the effect of small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

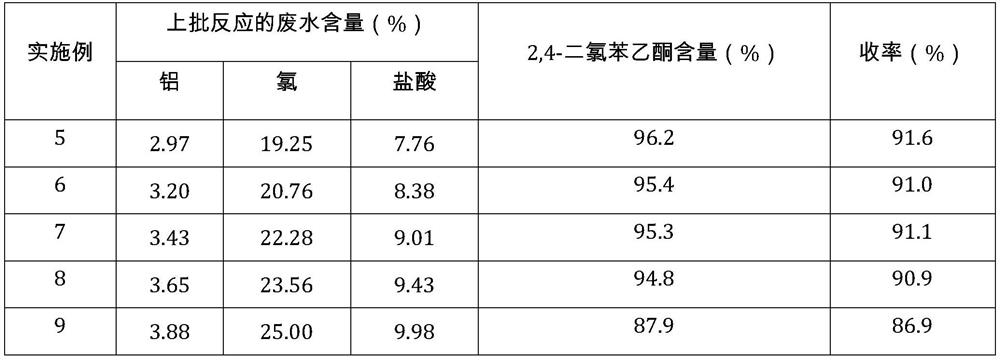

Examples

Embodiment 1

[0023] A kind of resource utilization method of 2,4-dichloroacetophenone waste water, comprises the following steps:

[0024] S1: Put 800g of 2,4-dichloroacetophenone wastewater into a four-necked bottle, add 8g of activated carbon, reflux for adsorption and decolorization, cool, and filter with suction. The filtrate 789.8g is dehydrated under negative pressure until the remaining 270g of the kettle liquid is determined. Aluminum 5.5%;

[0025] S2: Put 74.6g (98.5%, 0.5mol) of m-dichlorobenzene, the still liquid obtained in S1, and 200g of toluene into the four-necked flask, stir the mixture, bubble in hydrogen chloride, heat the reactant, and use a water separator to carry out The toluene is refluxed with water, and the acidic water is separated from the water separator, and the water is completed, and the toluene is removed at a negative pressure of -0.085MPa;

[0026] S3: Cool the material to 40°C, slowly add 40.5g (99%, 0.515mol) of acetyl chloride dropwise to the materia...

Embodiment 2

[0032] A kind of resource utilization method of 2,4-dichloroacetophenone waste water, comprises the following steps:

[0033] S1: Put 732g of 2,4-dichloroacetophenone waste water produced in Example 1 into the four-necked bottle, add 7.3g of activated carbon, decolorize by reflux adsorption, cool, filter with suction, dehydrate 714g of filtrate under negative pressure, and dehydrate to the still liquid The remaining 261g was determined to contain 5.5% aluminum;

[0034] S2: drop into the four-necked bottle 74.6g (98.5%, 0.5mol) of m-dichlorobenzene, the still liquid obtained in S1 and 200g of toluene, add anhydrous aluminum trichloride 2.5g (99%, 0.018mol), Stir the mixture, bubble in hydrogen chloride, heat the reactant, use the water separator to reflux the toluene with water, separate the acidic water from the water separator, and remove the toluene under a negative pressure of -0.085MPa;

[0035] S3: Cool the material to 40°C, slowly add 40.5g (99%, 0.515mol) of acetyl ch...

Embodiment 3

[0040] A kind of resource utilization method of 2,4-dichloroacetophenone waste water, comprises the following steps:

[0041] S1: Put 655g of 2,4-dichloroacetophenone wastewater produced in Example 1 into the four-necked bottle, add 6.6g of activated carbon, reflux for adsorption and decolorization, cool, and suction filter, dehydrate 632g of filtrate under negative pressure, and dehydrate to the kettle liquid The remaining 261g was determined to contain 5.5% aluminum;

[0042] S2: 74.6g (98.5%, 0.5mol) of m-dichlorobenzene, the still liquid obtained in S1 and 200g of toluene are dropped into the four-necked flask, and 1.4g (99%, 0.018mol) of aluminum hydroxide is added, and the mixture is stirred, Bubble hydrogen chloride, heat the reactant, use the water separator to carry out toluene reflux with water, separate the acidic water from the water separator, and remove the toluene with a negative pressure of -0.085MPa;

[0043] S3: Cool the material to 40°C, slowly add 40.5g (9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com