Elastic fiber as well as preparation method and application thereof

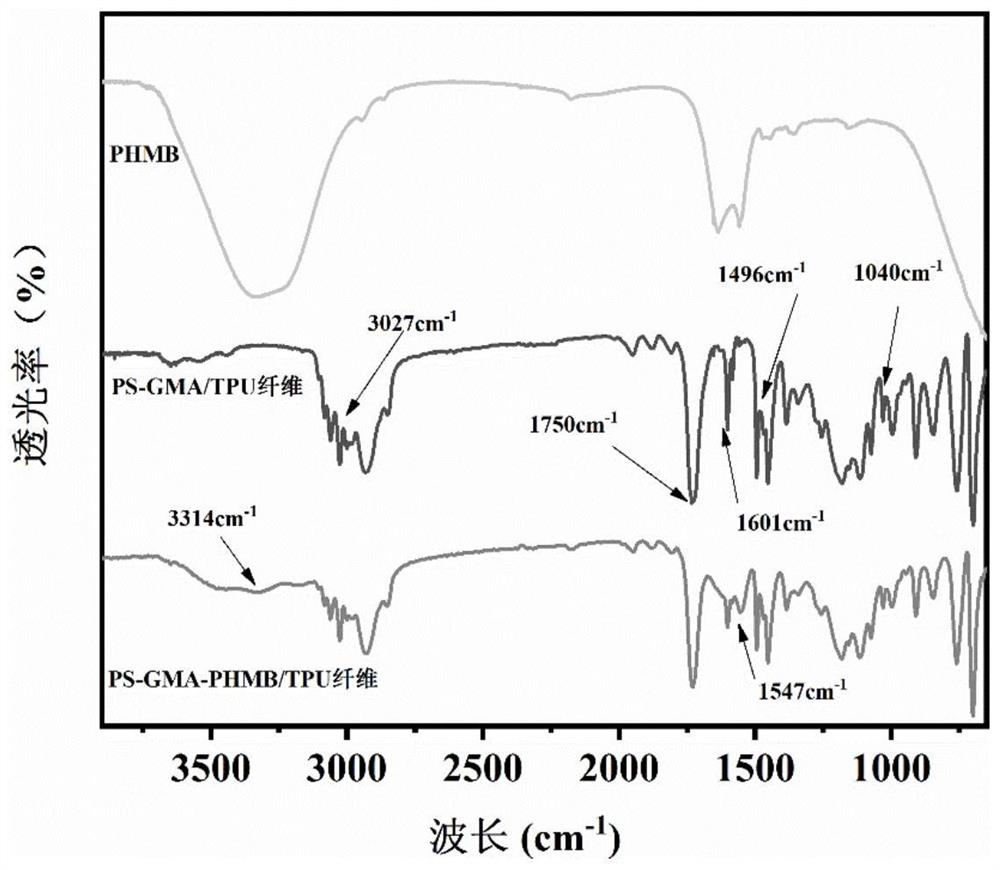

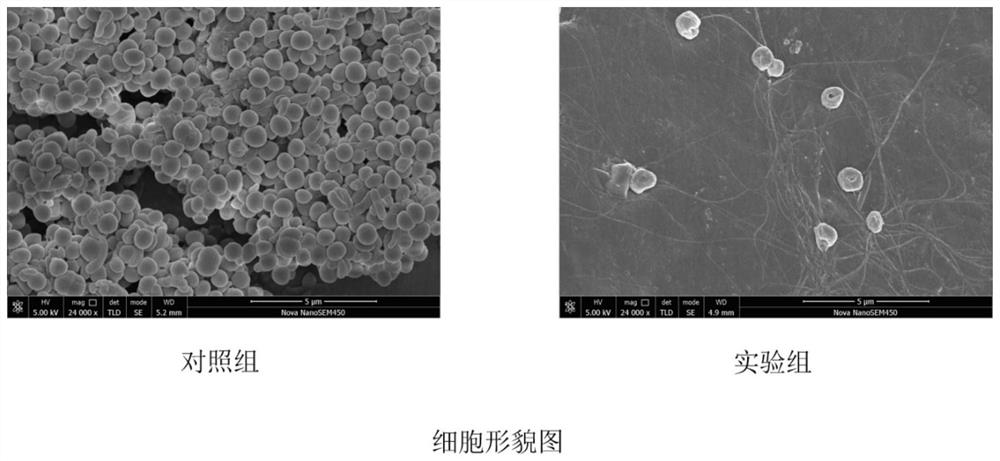

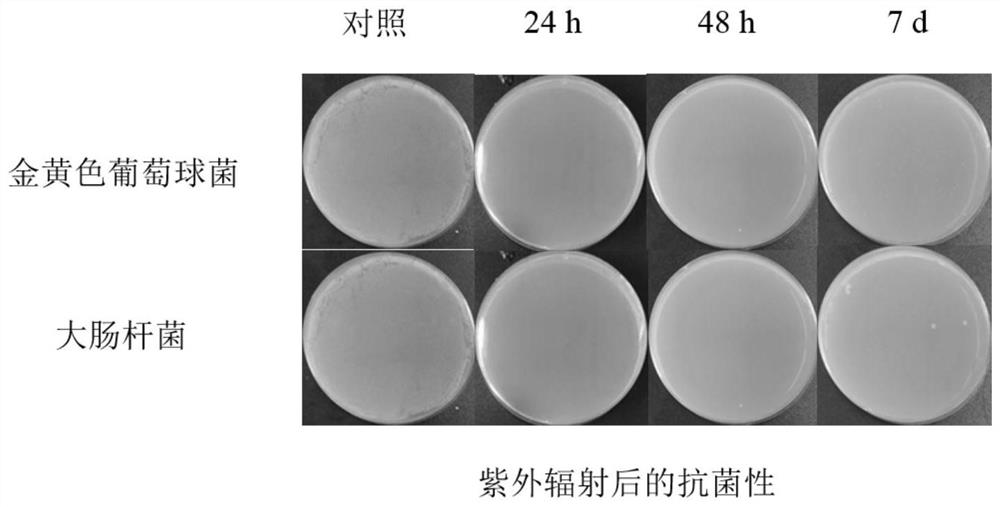

An elastic fiber, PS-GMA technology, applied in the field of textiles, can solve the problems of functional fibers or fabrics with difficult antibacterial performance, unreliable combination, low molecular weight, etc., to achieve continuous and stable antibacterial effect, excellent washing resistance, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the preparation of elastic fiber PS-GMA / TPU of the present invention

[0042]Put the TPU in an oven at 60°C to dry for later use. Configure a PVA aqueous solution with a mass fraction of 0.2%; configure AIBN, styrene, and GMA with a molar ratio of 1:50:25 into a uniform mixed solution, and then add it to the configured PVA aqueous solution (0.2% by mass fraction) to carry out Reaction: The reaction is pre-polymerized at 85°C for 2h, and then heated to 90°C for 4h. After the reaction is completed, the obtained PS-GMA is filtered, washed several times with ethanol and water, and dried to obtain the PS-GMA polymer. PS-GMA and TPU can be processed by wet spinning (made into a mixed spinning solution, the solvent of the spinning solution is DMF, the mass ratio of PS-GMA and TPU is 1:5, and the solid content of the spinning solution is 30%), dry spinning PS-GMA / TPU fibers were obtained by spinning (PS-GMA, TPU mass ratio 1:5) or melt spinning (prepared into sl...

Embodiment 2

[0043] Embodiment 2, the preparation of elastic fiber PS-GMA / TPU of the present invention

[0044] The preparation method of PS-GMA polymer is the same as embodiment 1, then PS-GMA and TPU are passed through wet spinning (being made into mixed spinning solution, and spinning solution solvent is DMF, and the mass ratio of PS-GMA, TPU is 1 :3, the solid content of the spinning solution is 20%); or by dry spinning (PS-GMA, TPU mass ratio 1:3) or melt spinning (prepared into slices, PS-GMA, TPU mass ratio 1:3 ) and other ways to obtain PS-GMA / TPU fiber.

Embodiment 3

[0045] Embodiment 3, the preparation of elastic fiber PS-GMA / TPU of the present invention

[0046] The preparation method of PS-GMA polymer is the same as embodiment 1, then PS-GMA and TPU are passed through wet spinning (being made into mixed spinning solution, and spinning solution solvent is DMF, and the mass ratio of PS-GMA, TPU is 1 :7, the solid content of the spinning solution is 32%); or by dry spinning (PS-GMA, TPU mass ratio 1:7) or melt spinning (prepared into slices, PS-GMA, TPU mass ratio 1:7 ) and other ways to obtain PS-GMA / TPU fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com