Method for strengthening and toughening high-strength steel local region

A high-strength steel, strengthening and toughening technology, applied in the field of strengthening and toughening high-strength steel, can solve the problem of processing area limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

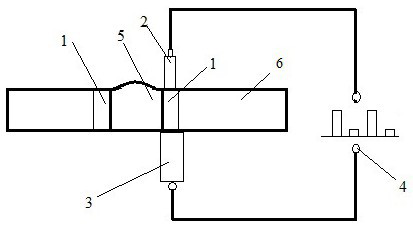

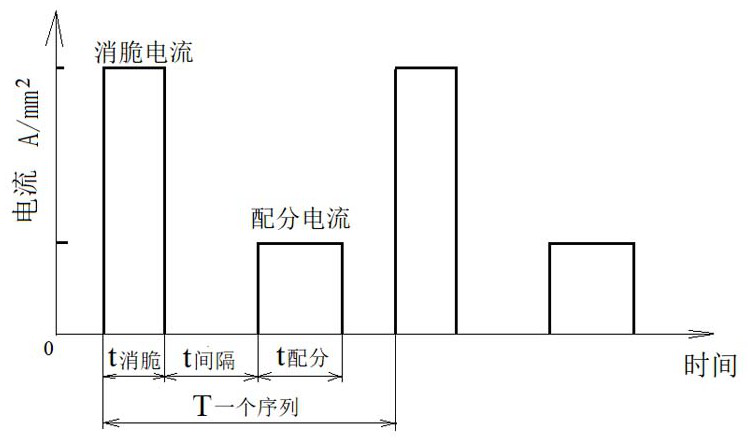

[0050] Such as figure 1 As shown, the high-strength steel samples adjacent to Comparative Example 1 were intercepted, and processed into tensile test and impact test samples respectively as in Comparative Example 1. Install a tungsten alloy electrode with a diameter of 5mm on the moving electrode end of the working platform. Place the tensile specimen to be pulsed on the bench. On the control panel, set the current value of the crisping pulse to 17 A / mm 2 , the width is 30ms, and the distribution pulse current is 4 A / mm 2 , the width is 300ms, the pulse interval is 300ms, the sequence frequency is 1Hz, and the number of pulse sequences is 3. Start the pulse generator switch, the tungsten electrode is driven by the working platform to move down to the surface of the workpiece, and the pulse sequence is sent out. After the sequence number reaches the set number, the pulse switch is closed. The tungsten electrode was raised under the driving of the working platform, and the ...

Embodiment 2

[0055] The pulse sequence parameters of this embodiment 2 and embodiment 1 are the same, the difference is that the sample of embodiment 2 adopts the air cooling state after FH690 welding. Tensile test obtains the yield strength 692 N / mm of embodiment 2 2 , the tensile curve of embodiment 2 sees Figure 10 , the impact toughness value of Example 2 is 0.45 J / mm 2 , the impact toughness value of base metal is 0.46 J / mm 2 .

Embodiment 3

[0059] The implementation of the pulse sequence parameters in this embodiment 3 is the same as that of the embodiment 1, except that the sample material of the embodiment 3 is A36 steel. Tensile test obtains the yield strength 371 N / mm of embodiment 3 2 , the tensile curve of embodiment 3 sees Figure 11 . The impact toughness value of embodiment 3 is 0.19 J / mm 2 , the impact toughness value of the base material in Example 3 is 0.24 J / mm 2 . The current spot diameter is given by Figure 13 It can be seen that the horizontal leucorrhea in the figure is the spot of current action, and the width is less than 0.2mm.

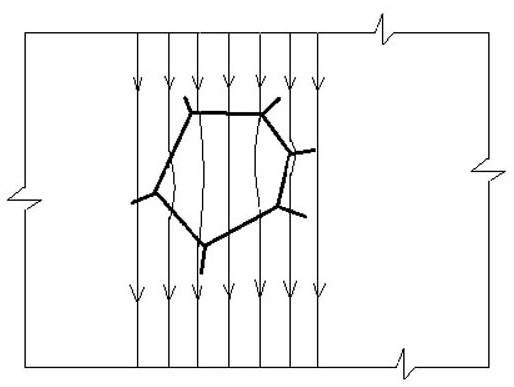

[0060] Such as Figure 8 As shown, the present invention is a localized method for strengthening and toughening high-strength steel. After applying a pulse sequence to the welding heat-affected zone of high-strength steel, the grains of the microstructure become finer. Figure 7 In the scanning electron microscope image of the fracture, dimples appear on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com